Local air return system capable of being quickly constructed

A local and rapid technology, applied in mine/tunnel ventilation, mining equipment, earthwork drilling and mining, etc., can solve problems such as increased excavation volume of return air roadway, difficult construction of ventilation shaft, and restriction of mining progress, etc., to achieve reduction The amount of excavation works, the structure is simple and reliable, and the effect of improving ventilation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and examples, but the present invention is not limited in any way. Any changes or improvements made based on the teaching of the present invention belong to the protection scope of the present invention.

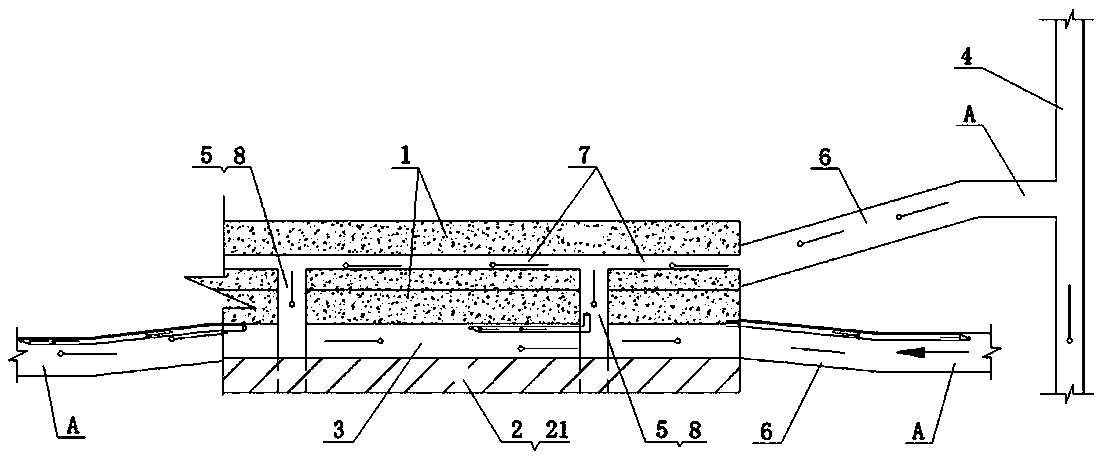

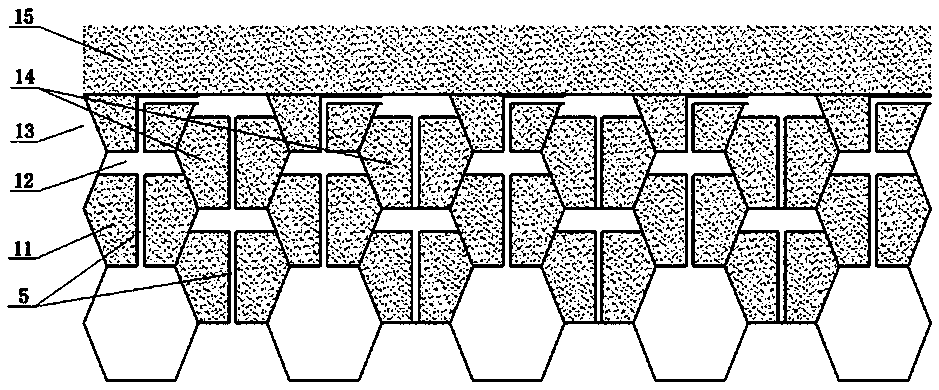

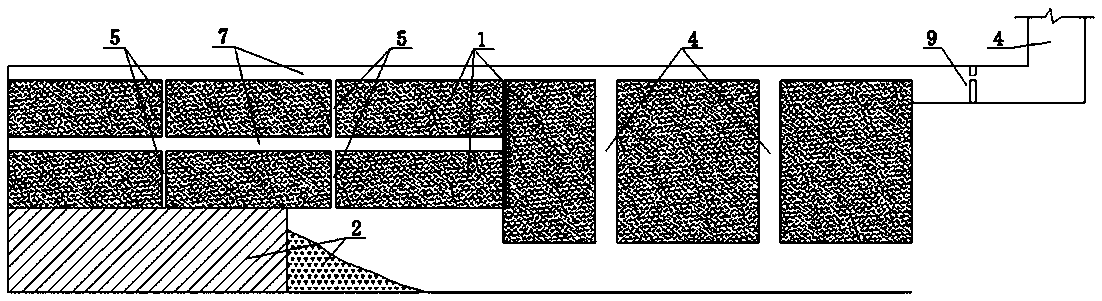

[0012] Such as Figures 1 to 4 As shown, the present invention includes goaf filling layer 1, ore body 2, vein-along roadway 3, return air shaft 4, and return air duct 5, and described vein-along roadway 3 is arranged along the direction of ore body 2, and described vein-along roadway 3 and the top of its extending direction is arranged with a goaf filling layer 1, and the return air duct 5 is vertically or obliquely embedded in the gob filling layer 1, and the lower end of the return air duct 5 is connected to the roadway 3 along the vein or extends into the roadway along the vein. The extension direction of the vein roadway 3 and the upper end is connected to the retu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com