Fan control method and system and electrical appliance equipment provided with heat dissipation fan

A control system and fan technology, applied in fan control methods, electrical equipment, and system fields, can solve the problems of not being able to reflect the temperature rise of devices in the electrical cavity in real time, the impact of the life of the driver chip, and the inability to obtain noise status, etc., to ensure the service life , reduce equipment maintenance costs, the effect of simple circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

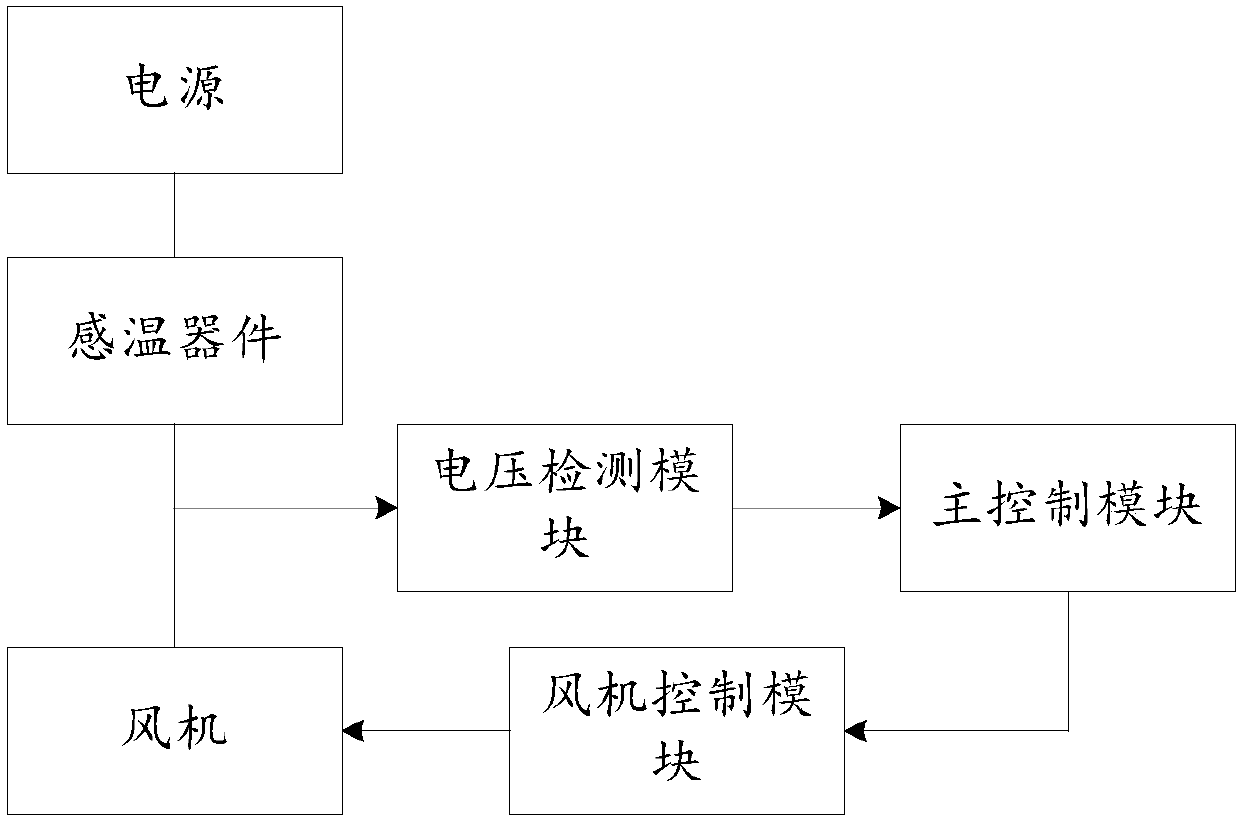

[0049] Such as figure 1 As shown, the present invention provides a fan control system, including:

[0050] Temperature sensing device, the temperature sensing device is connected between the fan voltage input terminal and the power supply, and is arranged near the important components in the electrical appliance or in the area of poor heat dissipation in the electrical appliance, for sensing the temperature change of the environment where it is located, the temperature sensing device The resistance value of the device changes with temperature;

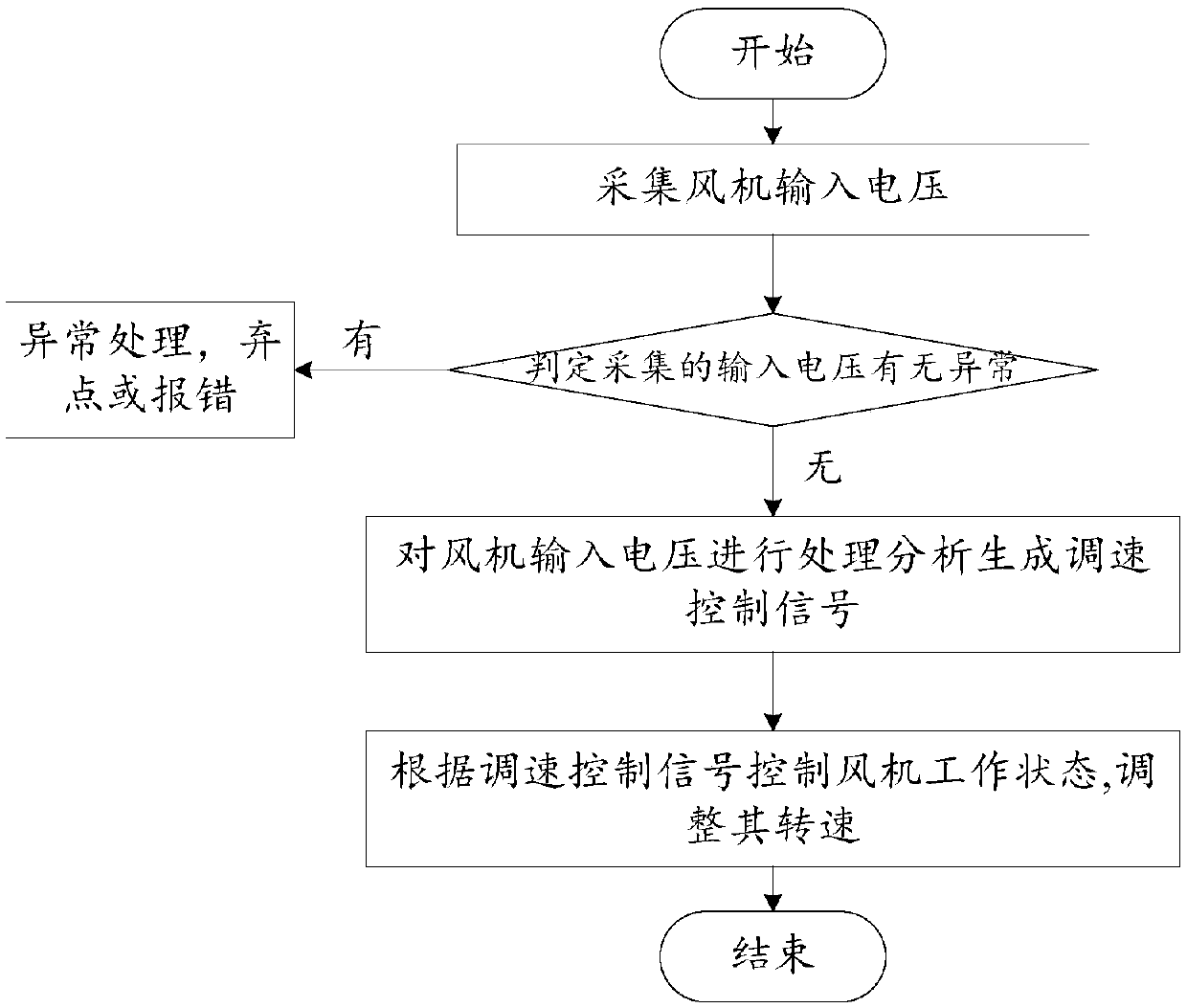

[0051] The voltage detection module is connected to the input terminal of the fan voltage and used to collect the input voltage of the fan;

[0052] The main control mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com