An evaporating tube combustion chamber

An evaporation tube and combustion chamber technology, applied in combustion chambers, continuous combustion chambers, combustion methods, etc., can solve the problems of limited atomization effect of large-scale particle size droplets, widen the stable working boundary, reduce the risk of flameout, reduce the The effect of smoke index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

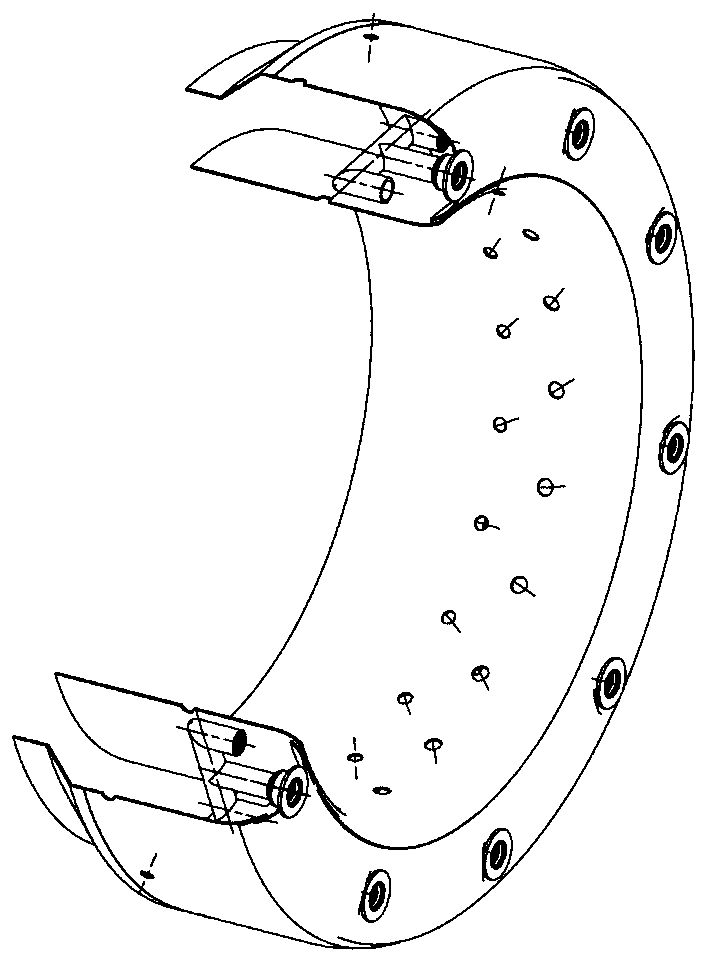

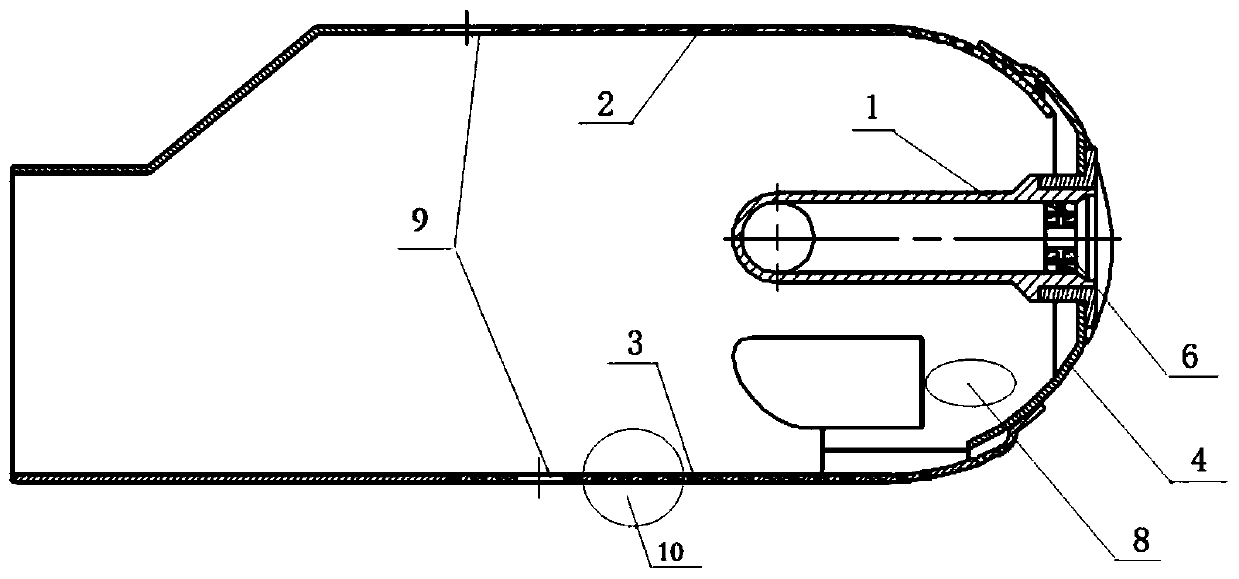

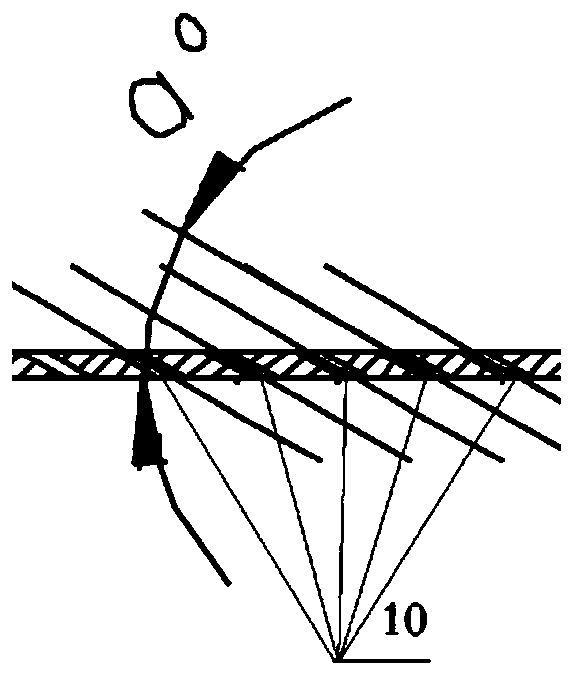

[0029] Such as Figure 1~5 As shown, the evaporating tube combustion chamber of the present invention has a main structure including evaporating tube assembly 1, flame tube outer tube 2, flame tube inner tube 3 and flame tube head 4 and other components, and the components are integrated by welding, wherein The internal area formed between the outer cylinder 2 of the flame cylinder, the inner cylinder 3 of the flame cylinder and the head 4 of the flame cylinder forms a flow field space in the combustion chamber. The evaporating tube assembly 1 at least includes a plurality of evaporating tubes 5 uniformly distributed along the circumference of the flame tube head 4 , and an inlet swirler 6 and an outlet swirler 7 arranged at the inlet and outlet of the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap