Connecting rod assembly, piston type compression mechanism and refrigerator

A technology of connecting rod assembly and compression mechanism, which is applied to connecting rods, liquid variable capacity machinery, pump components, etc., can solve problems such as large oil discharge rate of compressors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

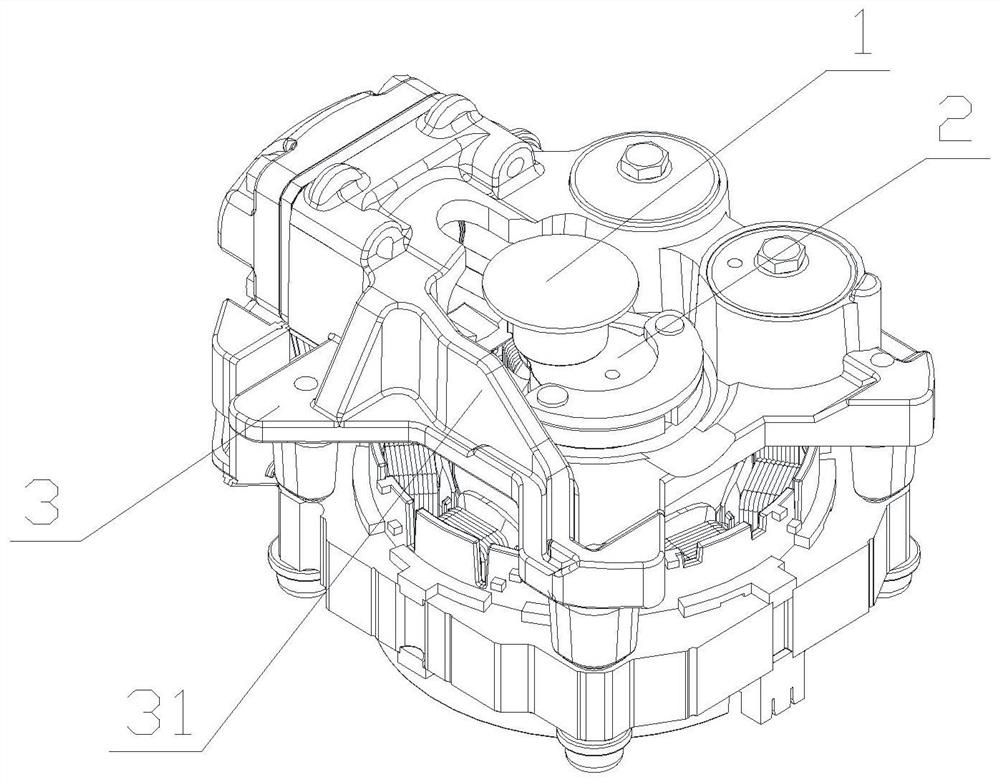

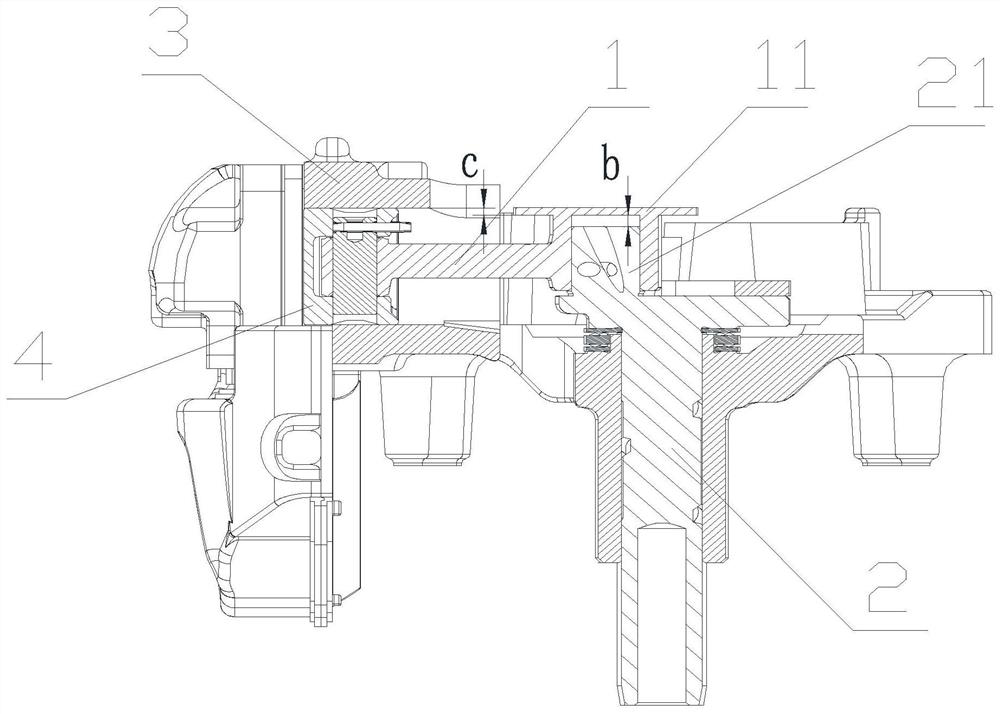

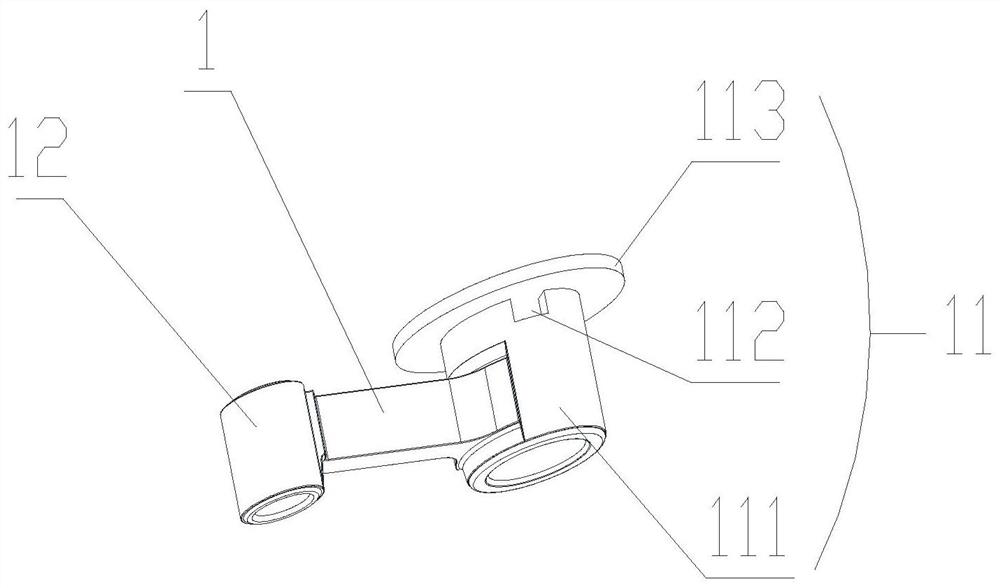

[0031] see in conjunction Figure 1 to Figure 6 As shown, according to an embodiment of the present application, a connecting rod assembly includes:

[0032] connecting rod 1, including a first end 11 connected to the eccentric shaft 21 of the crankshaft 2;

[0033] The first end 11 includes a ring body 111 and a top cover 113. An oil storage space is arranged inside the ring body 111. The top cover 113 is arranged on one end of the ring body 111 and covers at least part of the oil storage space. oil space; the ring body 111 is sheathed on the outer periphery of the eccentric shaft 21; the first end 11 is provided with an oil throwing hole 112 communicating with the oil storage space; when the crankshaft 2 rotates, the The oil on the crankshaft 2 is thrown out through the oil throwing hole 112 .

[0034] Since the conventional crankshaft 2 is provided with an oil supply hole, the oil at the bottom is delivered to the top of the crankshaft 2 for lubricating the first end 11 a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap