Tractor protective device testing platform and testing method thereof

A protection device, tractor technology, applied in the direction of measuring device, testing of mechanical parts, testing of machine/structural parts, etc., can solve the problems of unsafe, low precision, single function, etc., and achieve the effect of convenient disassembly and assembly and high precision

Pending Publication Date: 2018-02-23

LUOYANG XIYUAN VEHICLE & POWER INSPECTION INST

View PDF17 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

When carrying out longitudinal loading test and lateral loading test, some need multiple hydraulic cylinders to complete the longitudinal and lateral loading, and some need to move the loading device or the test piece by driving multiple times during the test, the operation is complicat

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

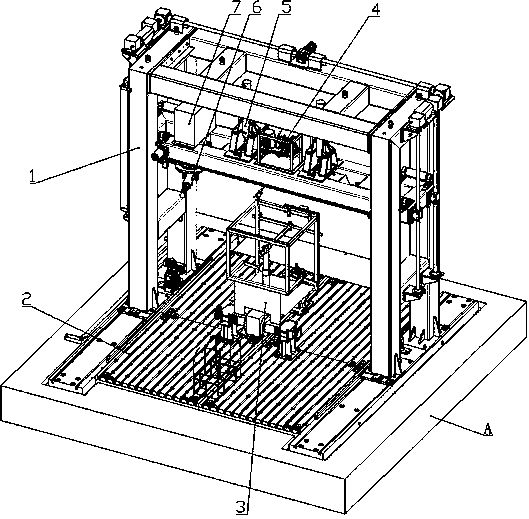

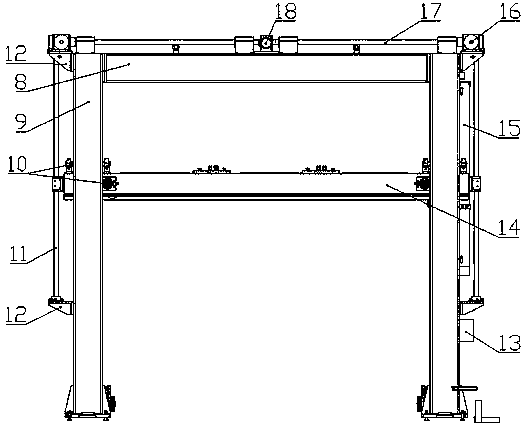

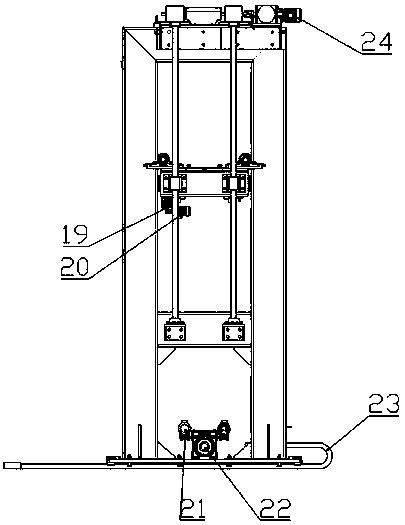

The invention provides a tractor protective device testing platform and a testing method thereof. The testing platform comprises a mechanical structure system which comprises a gantry framework assembly, a cast iron platform assembly and a tested object tooling assembly; a hydraulic system which comprises a hydraulic pressure station, a crushing oil cylinder group of an integrated force displacement senor, a rotating oil cylinder group of the integrated force displacement sensor and a hydraulic pipeline and an electrical control system which comprises a control cabinet and the like; the gantryframework assembly and the tested object tooling assembly are installed on the cast iron platform assembly which is fixed to a foundation A; the hydraulic pressure station and the crushing oil cylinder group of the integrated force displacement senor are installed on the gantry framework assembly, the rotating oil cylinder group of the integrated force displacement sensor is installed on the gantry framework assembly in a sliding mode, the hydraulic pipeline is connected with input ends and output ends of the hydraulic pressure station, the crushing oil cylinder group of the integrated forcedisplacement senor and the rotating oil cylinder group of the integrated force displacement sensor separately; the control cabinet is installed on the gantry framework assembly, and a computer is located outside the gantry framework assembly. The testing method is scientific and reasonable and high in practicability.

Description

technical field [0001] The invention belongs to the field of tractor test equipment, and relates to a tractor protective device test bench and a test method thereof. Background technique [0002] At present, there are mainly three types of static tests on tractor protective devices at home and abroad: longitudinal loading test, lateral loading test and crushing test. The purpose of the test is to verify the rigidity and strength of the tractor protective device, so as to minimize the possibility of injury to the driver due to a rollover accident during normal operation of the tractor. [0003] In June 2014, Chen Xiaoling from Nanjing Agricultural University published "Design and Research on the Strength Test Bench of Tractor Protective Devices" on CNKI, pointing out that the test bench is composed of two major devices, namely: horizontal loading device and crushing loading device. The horizontal loading device mainly consists of four parts: a vertical loading beam, a horizo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M13/00

CPCG01M13/00

Inventor 韩建刚陈俊杰王宁毅李瑞强刘琨邓浩刘江辉赵亚燊张琳琳石峰郭蕊蕊李华雷杨倩雯

Owner LUOYANG XIYUAN VEHICLE & POWER INSPECTION INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com