Transport and inspection control system of converter station hardware joint, and work method thereof

A technology for management and control systems and converter stations, applied to instruments, data processing applications, resources, etc., can solve problems such as difficult operation and maintenance management, cumbersome input data, messy management data, etc., to improve operation and maintenance efficiency and information extraction speed , the effect of reducing the number of DC outages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

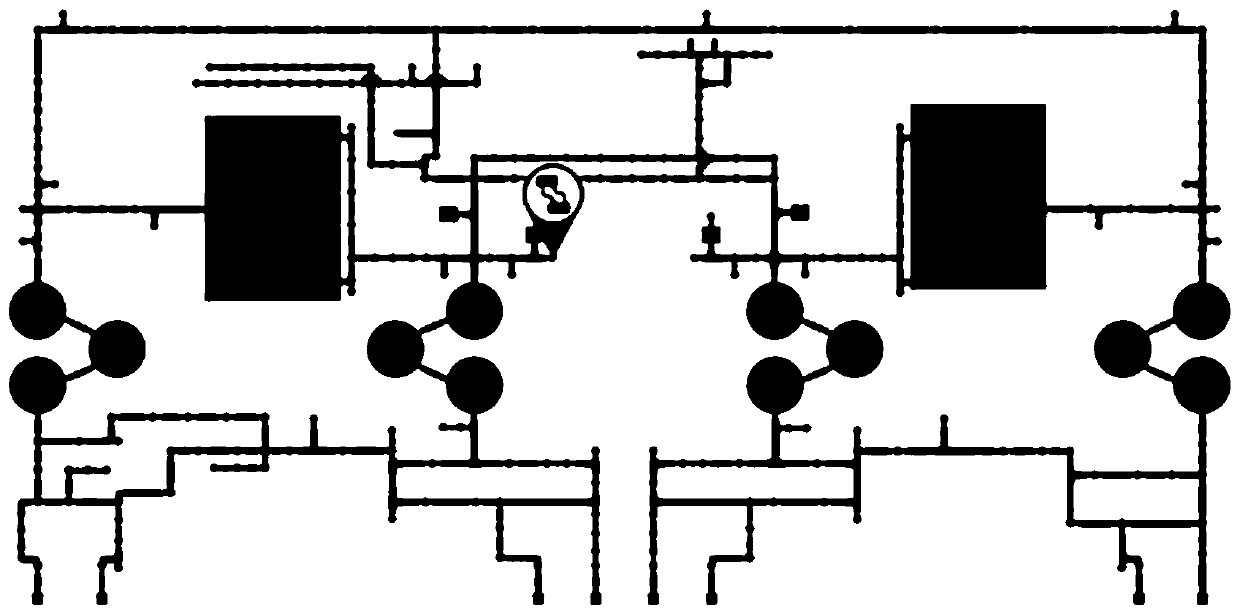

[0046] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0047] The present invention includes:

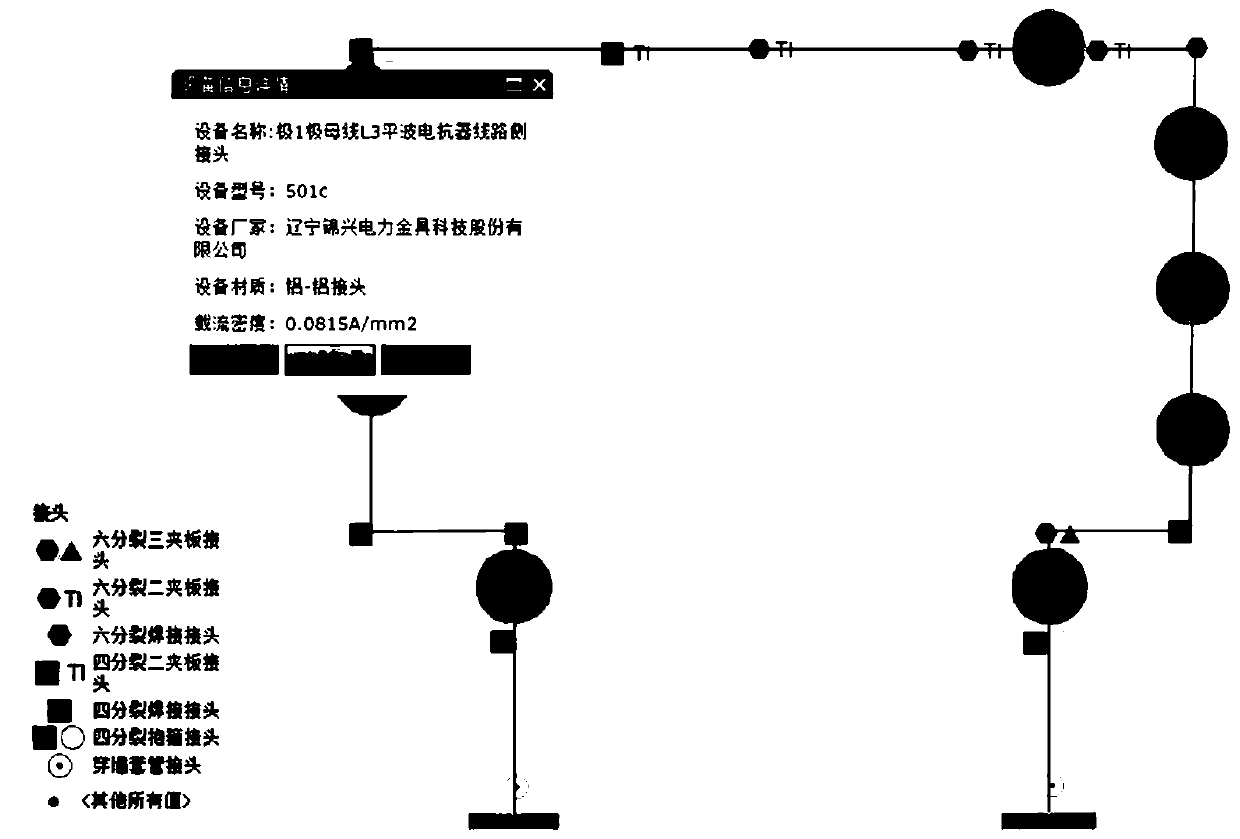

[0048] Equipment management module: dual naming of joints, including on-site naming for on-site identification and file naming for file management, on-site naming and file naming are associated, file management is integrated, and the joints in the station are named one by one, and on-site production Identification plate, which integrates the basic information into the corresponding joint file in the system; the basic information includes the equipment model of the fitting joint, equipment manufacturer, and current-carrying density;

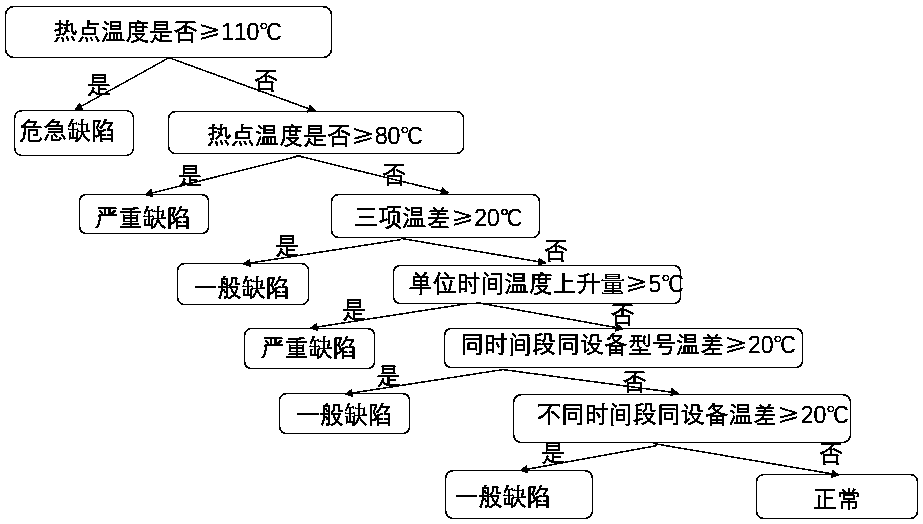

[0049] Fault prediction module: used for intelligent prediction according to the established fault judgment method; the comprehensive judgment formulation strategy includes: single hot spot alarm temperature, single hot spot temperature rising trend alarm, three-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com