Positioning switch box

A switch box and positioning arm technology, applied in the direction of electrical switches, electrical components, circuits, etc., can solve the problems of easy to get crooked, and the bottom box is not easy to adjust the position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

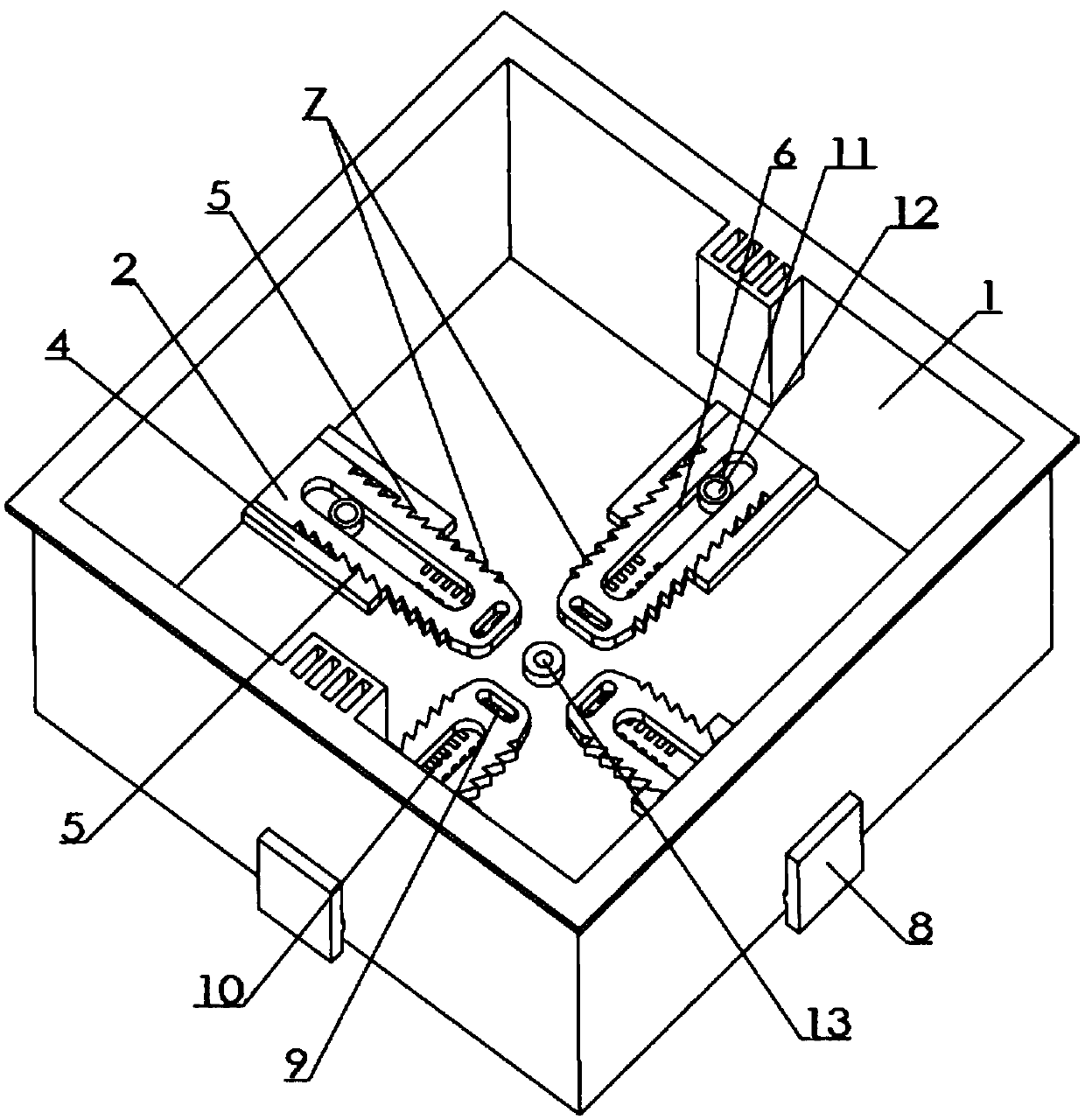

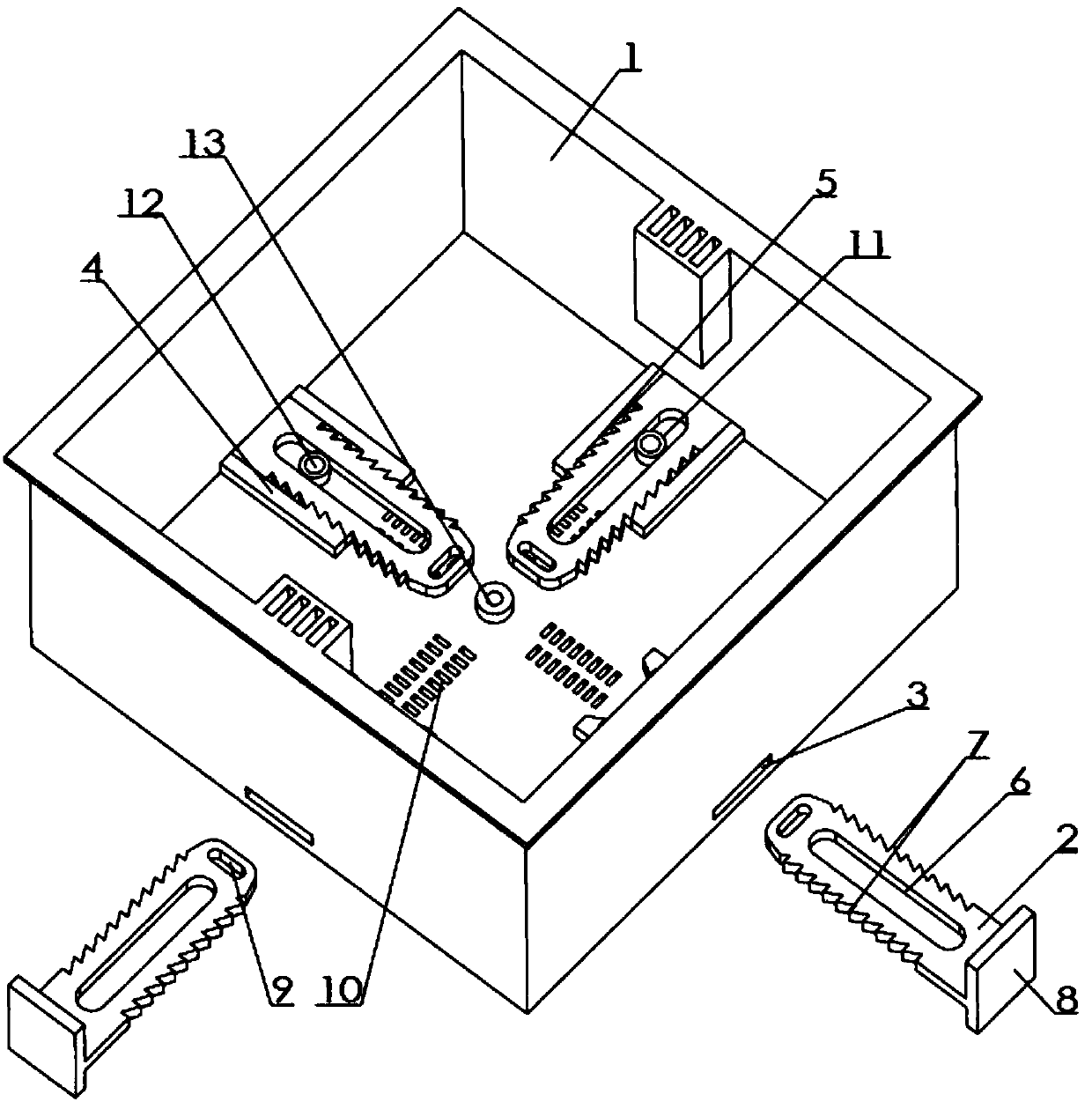

[0014] Examples of the present invention figure 1 , 2 As shown, the positioning switch box is provided with a bottom box 1 and a positioning support arm 2, and the bottom of the four walls of the bottom box is centered and close to the bottom of the box. There are barbs 5 on the opposite surfaces of the inner ends of the two projections, the inner ends of the positioning arms extend from the gap to the bottom middle of the bottom box through the slideway, and the middle part of the positioning arms is provided with a strip slide rail 6, so that Its two sides have the elasticity of deformation, and the edges of both sides of the positioning support arm are provided with teeth 7 that cooperate with the barbs. The inner end of the arm is provided with a dial hole 9, and the bottom box bottom of the lower part of the positioning support arm is provided with bottom holes 10 distributed along the positioning support arm. The tool moves the positioning support arm outwardly, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com