Jigs for Flange Shaping

A flange and fixture technology, which is applied in the direction of gear teeth, gear cutting machines, manufacturing tools, etc., can solve the problems of easy movement of the flange plate and few fixed limit positions, so as to achieve fixed and stable, not easy to move or deviate moving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

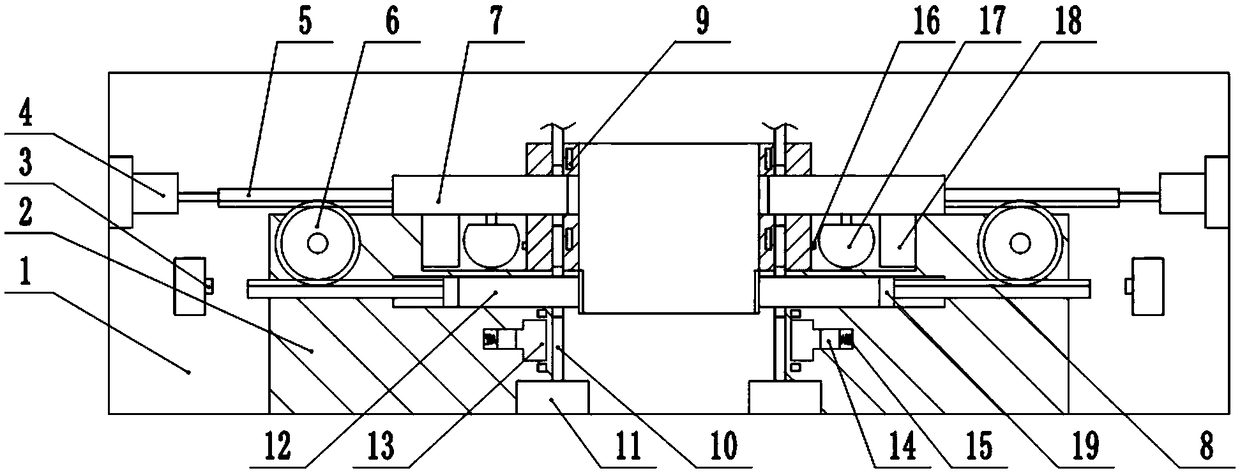

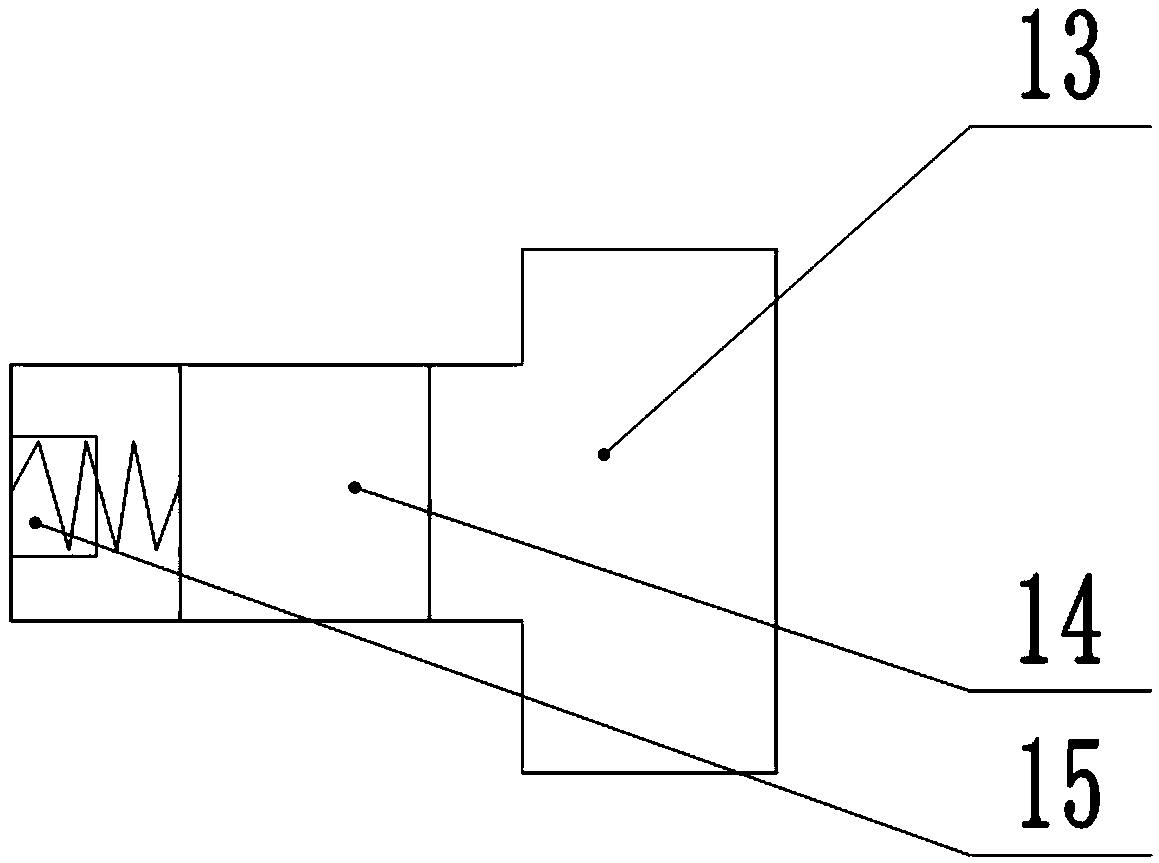

[0018] The reference signs in the drawings of the description include: frame 1, positioning plate 2, third button 3, cylinder 4, first rack 5, gear 6, pressing rod 7, second rack 8, electric heating wire 9 , cold air channel 10, air supply box 11, negative pressure channel 12, water storage tank 13, first piston 14, second button 15, first button 16, water bag 17, pressure plate 18, second piston 19.

[0019] Example basic reference figure 1 and figure 2 Shown: The jig for flange gear shaping includes frame 1, on which frame 1 is welded with positioning disc 2, on which positioning disc 2 is provided with positioning grooves, and on positioning disc 2, there are two pressure plates symmetrical to the center of the positioning slots. The compression device includes a compression rod 7 for compressing the flange, and a cylinder 4 for driving the compression rod 7 to slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com