Conical shaft coupler

A coupling and tapered shaft technology, which is applied in the field of tapered shaft couplings, can solve the problems of inconvenient disassembly, troublesome installation, disengagement of the shaft head and the connecting pipe, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

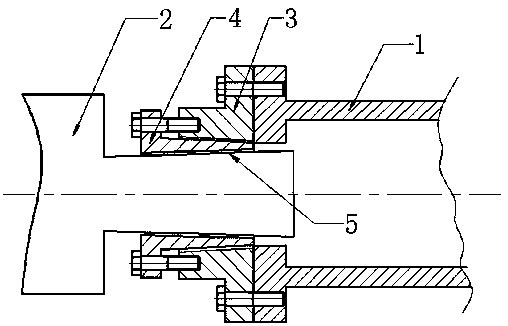

[0012] The tapered shaft coupling of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0013] As shown in the figure, the tapered shaft coupling of the present invention includes a connecting pipe 1 and a shaft head 2 located at both ends of the connecting pipe. Both ends of the connecting pipe 1 are provided with a shaft with an inner tapered hole for installing the shaft head. The sleeve 3 also includes a positioning sleeve 4 for installation between the shaft sleeve and the shaft head. The connection end of the shaft head 2 is set as a truncated cone structure 5 whose diameter gradually increases from the root of the shaft head. The maximum diameter is smaller than the minimum diameter of the inner taper hole of the shaft sleeve 3, so that the installation can be carried out smoothly. The positioning sleeve 4 is a two-half split structure, and the positioning sleeve 4 has an inner hole th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com