independent tensioner

A tensioning device and tensioning technology, which is applied in transmission devices, belts/chains/gears, mechanical equipment, etc., can solve the functional hazards of the tensioning device, and cannot guarantee reliable and durable sealing between the piston hole and the tensioning piston, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

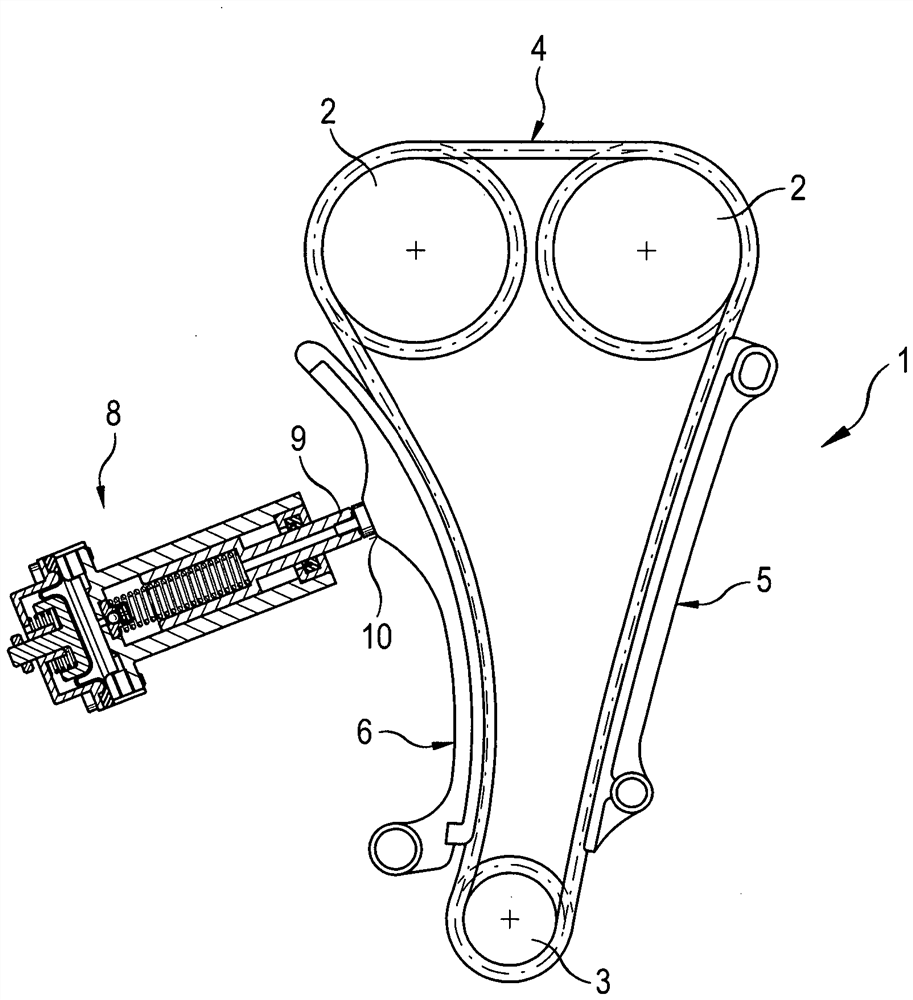

[0029] combustion motor in figure 1 The control chain transmission 1 shown in the figure comprises two upper camshaft sprockets 2, one lower crankshaft sprocket 3, a control chain 4 wound around them, a A guide rail 5 guiding the control chain 4 in the tension side of the device 1 and a pivotably arranged tension rail 6 in the loose side of the control chain drive 1 Squeeze towards the control chain 4. The tensioning rail 6 is pressed onto the control chain 4 by means of a separate tensioning device 8 fastened in the combustion motor. In this case, the separate tensioning device 8 is designed as a flange tensioner and is flanged to the motor component 7 via the fastening means 12 , see also figure 2 . In this case, the piston rod 9 of the tensioning device 8 presses against the pressing area 10 of the pivotably arranged tensioning rail 6 and thus pushes it into the loose side of the control chain drive 1 . The control chain 4 is tensioned.

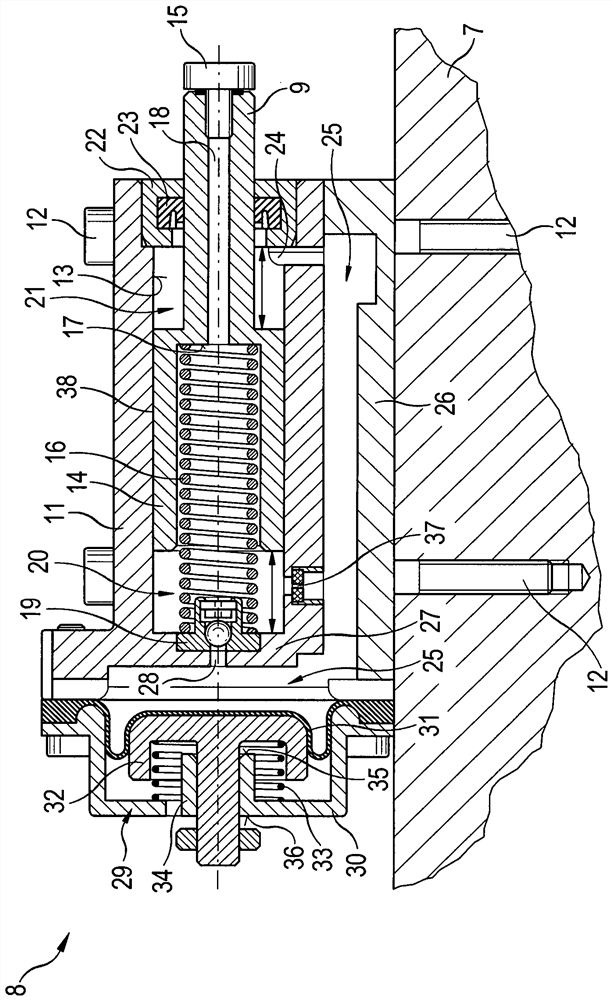

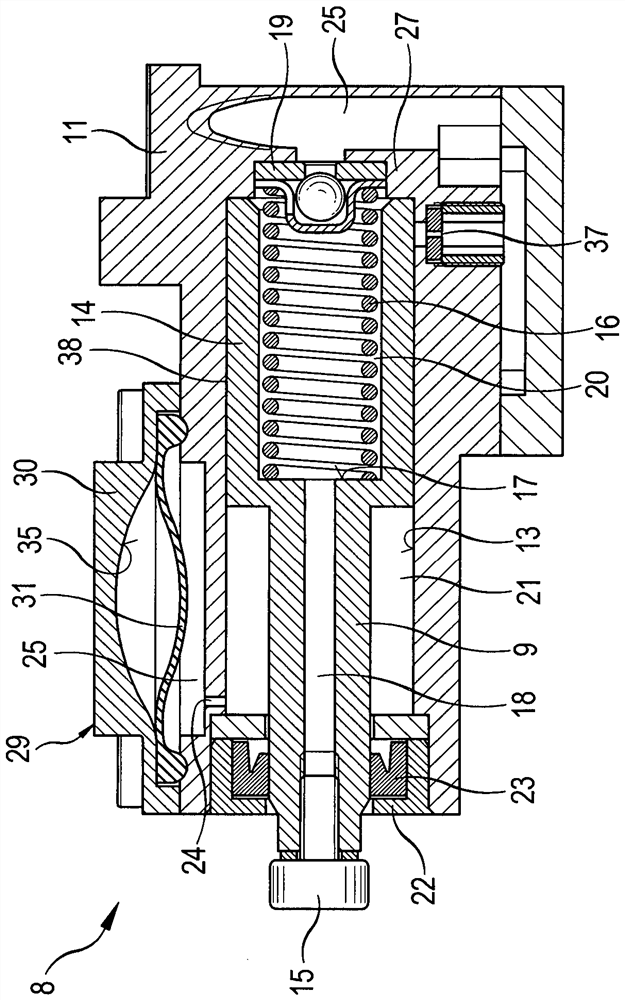

[0030] figure 2 The configu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com