Roller drive

A technology for rollers, drive systems, applied in electric components, asynchronous induction motors, transportation and packaging, etc., can solve problems such as limiting the size of internal motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

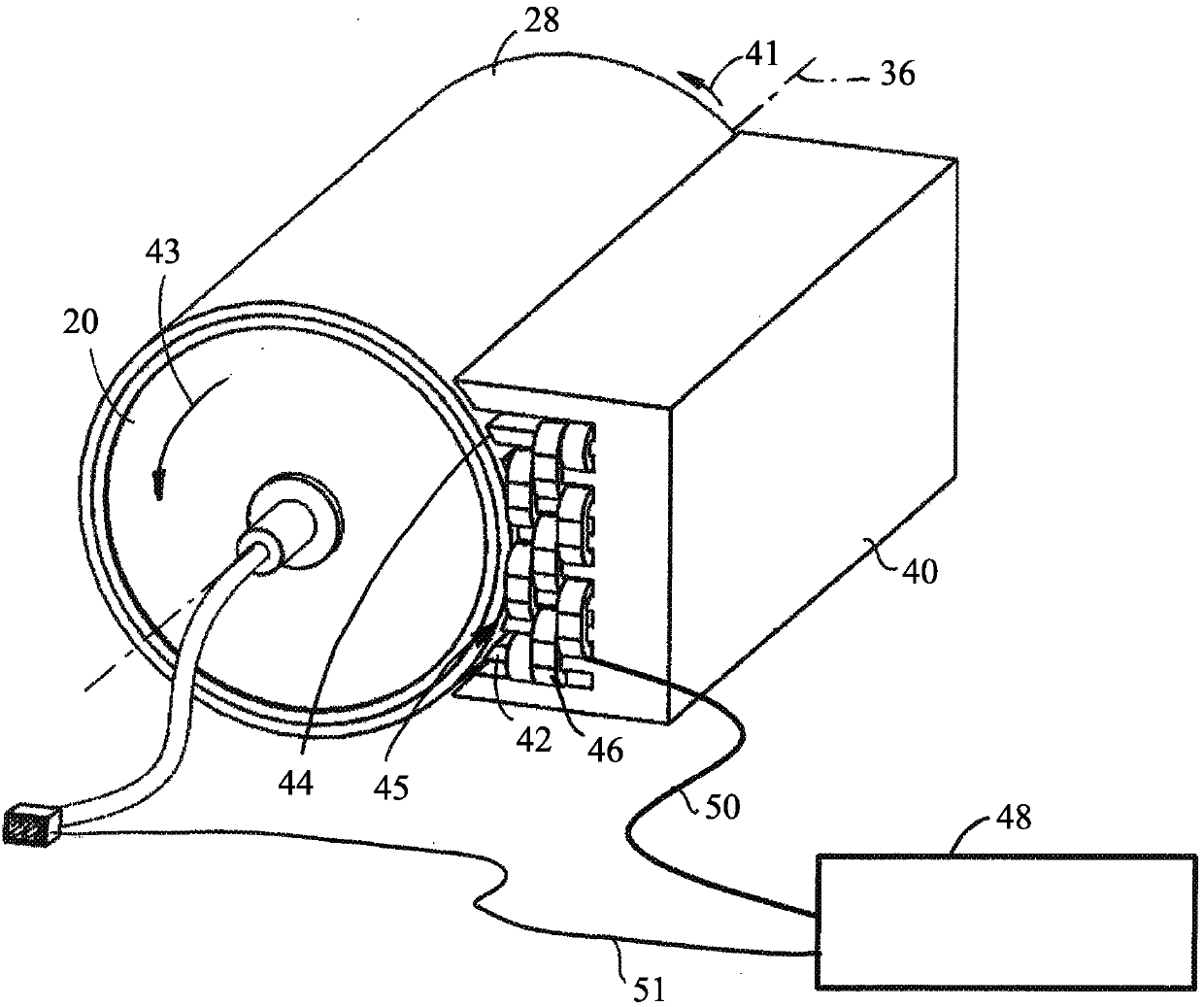

[0019] figure 2 A power assist drive system for a motorized drum embodying features of the present invention is shown in . The stator 40 is positioned close to the cylindrical outer housing 28 of the motorized roller 20 which is stationary mounted at a fixed position in the conveyor frame (not shown). The main drive of the motorized drum is its integrated electric motor. The stator 40 has a pole array 42 terminating in a pole face 44 adjacent the housing 28 . Each pole 42 is surrounded by a winding 46 (eg, a three-phase winding). The pole face 44 defines a curved plane whose shape is complementary to the outer shell 28 of the motorized drum 20 across the air gap 45 . The stator 40 is the source of an external magnetic field positioned proximate to the outer housing 28 .

[0020] The stator 40 extends axially along most of the length of the motorized drum 20 , and circumferentially along only a portion of the cylindrical outer casing 28 . The stator 40 generates flux waves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com