Secondary bran-removing device with multifunctional vibration screen

A vibrating screen, multi-functional technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of increasing product quality, difficult maintenance, complex structure, etc., and achieve the effect of easy popularization and application, easy maintenance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

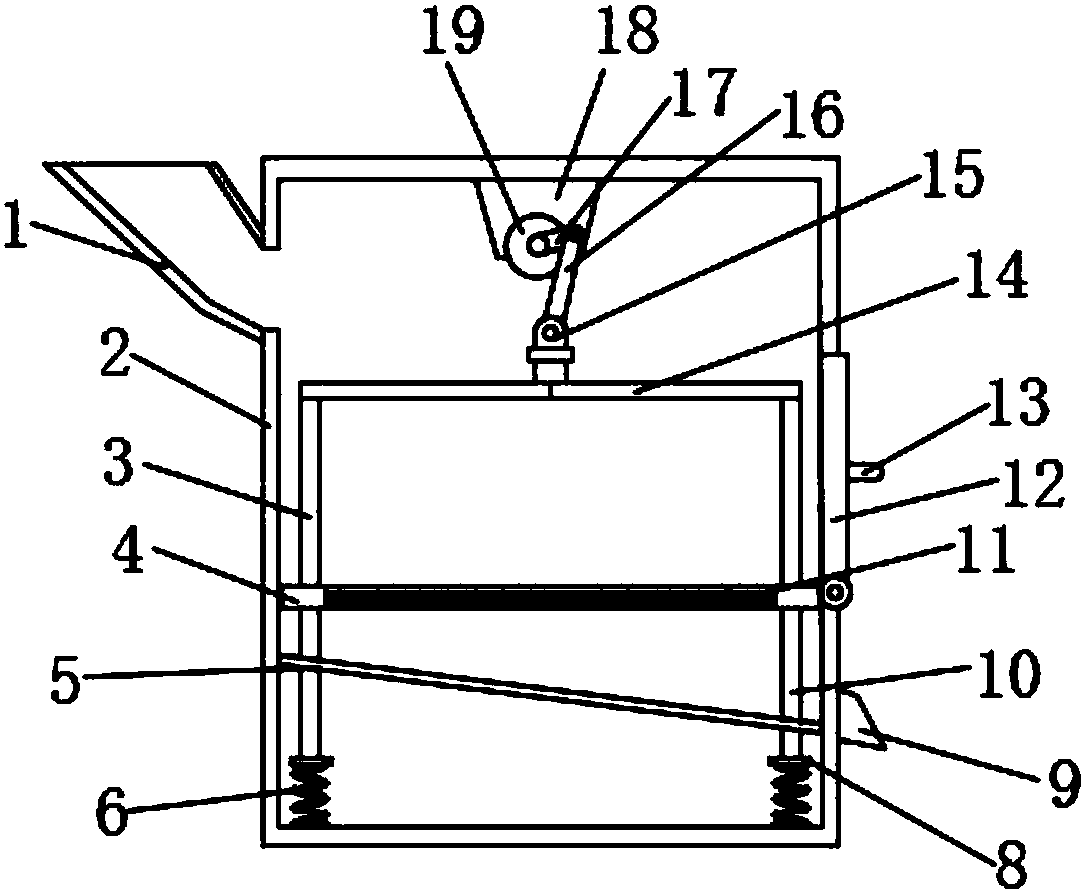

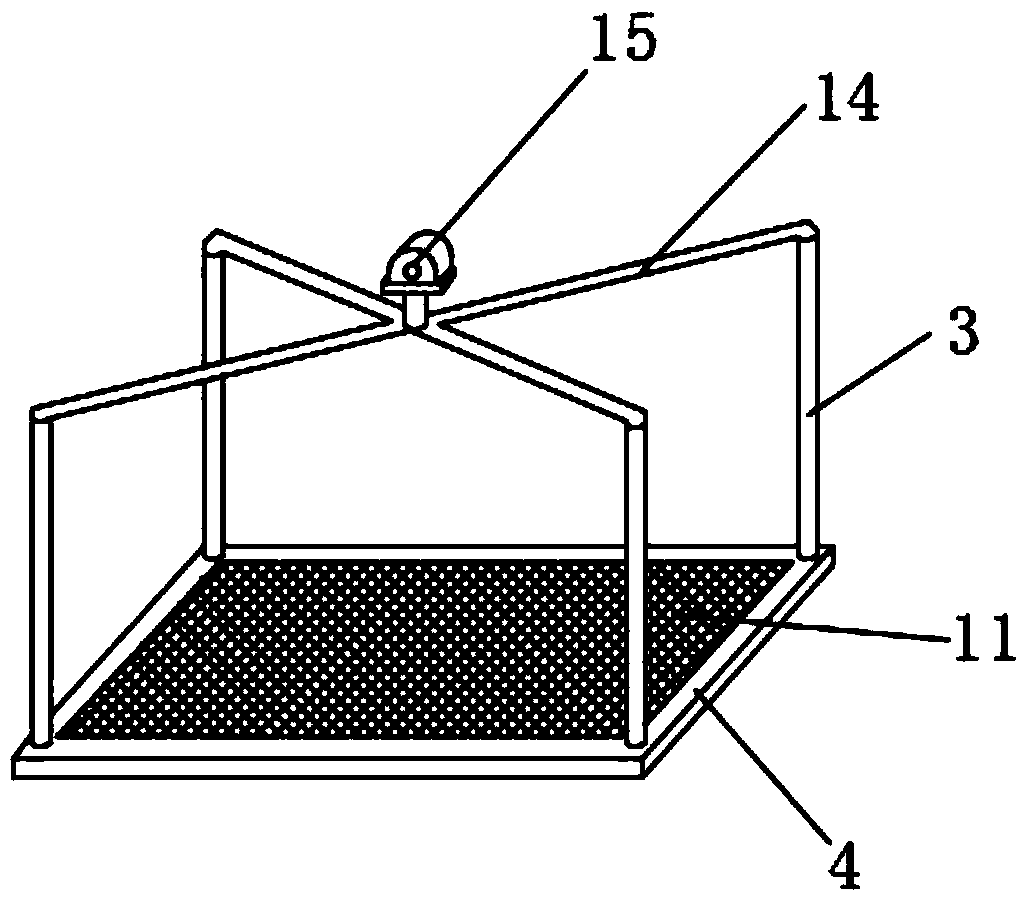

[0017] Embodiment 1: as Figure 1-2 As shown, a secondary bran removal device of a multifunctional vibrating screen includes a sieve cabin 2, the middle part of the inner cavity of the sieve cabin 2 is fixedly connected with a guide plate 5, and the middle part of the material guide plate 5 is movably connected with a limit rod 10, which limits The bottom of the position rod 10 is fixedly connected with a baffle plate 8, and the bottom of the baffle plate 6 and the sieve cabin 2 is fixedly connected with a switching spring 6, and the top of the limit rod 10 is fixedly connected with a screen frame 4, and the inner wall of the screen frame 4 is fixed. A screen 11 is connected, the top of the screen frame 4 is fixedly connected with a connecting rod 3, the top of the connecting rod 3 is fixedly connected with a vibrating screen 14, the top of the vibrating screen 14 is fixedly connected with a pin 15, and the top of the pin 15 is rotatably connected with a The top of the push ro...

Embodiment 2

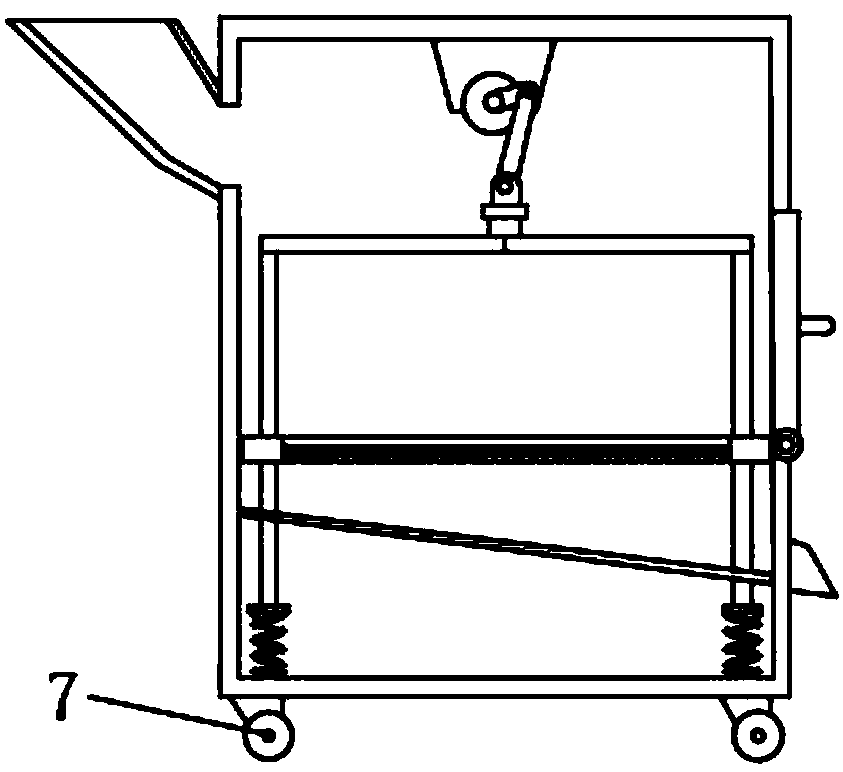

[0019] Such as image 3 , On the basis of Embodiment 1, the bottom of the sieve cabin 2 is fixedly installed with moving wheels 7, and there are at least four groups of moving wheels 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com