A lightweight spacecraft main structure

A technology of spacecraft and main structure, applied in the direction of aerospace vehicles, aircraft, aerospace equipment, etc., can solve the problem of increasing the installation space of equipment, and achieve the effect of reducing the weight of the structure, light weight, and lowering the height of the center of mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

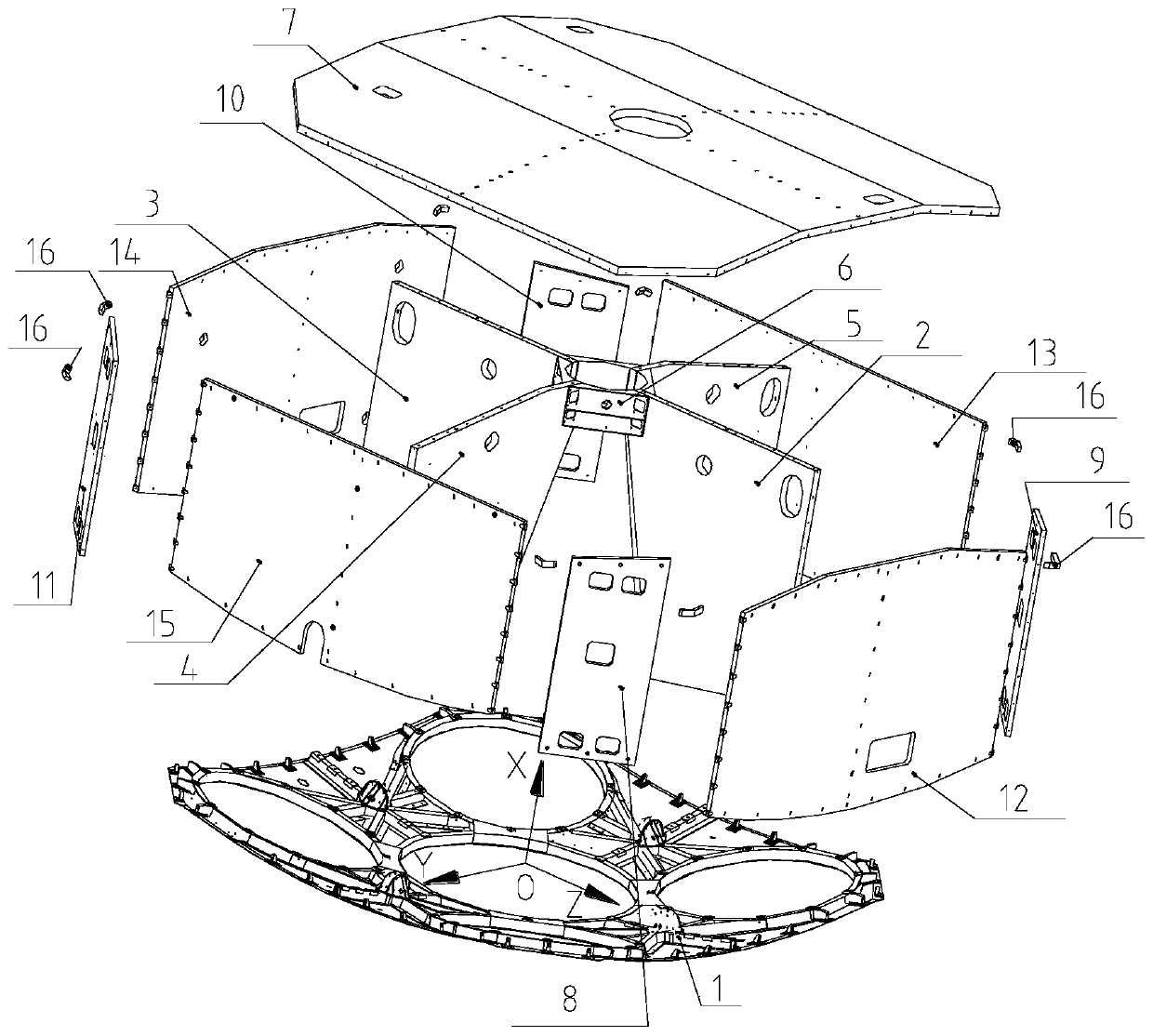

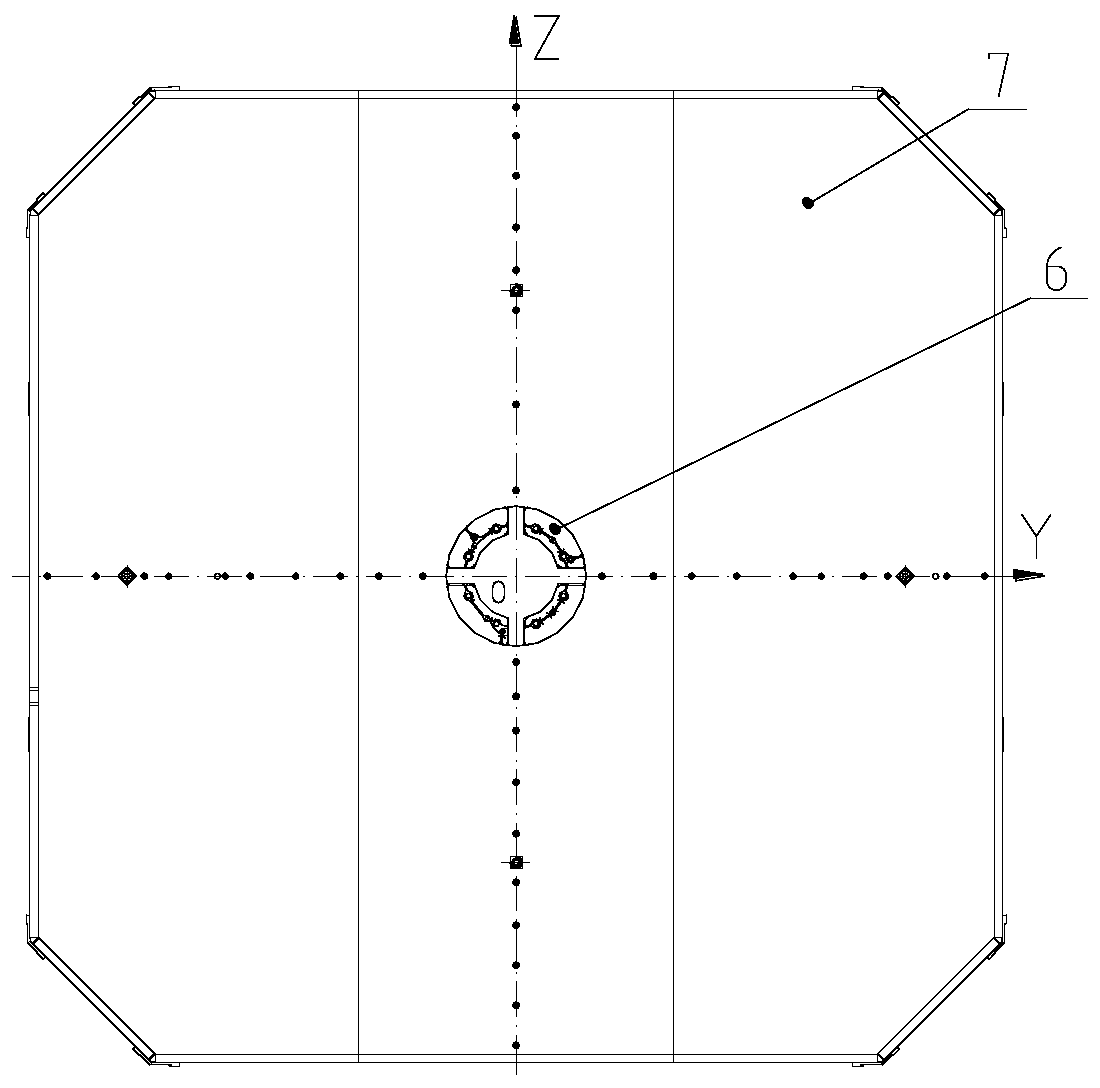

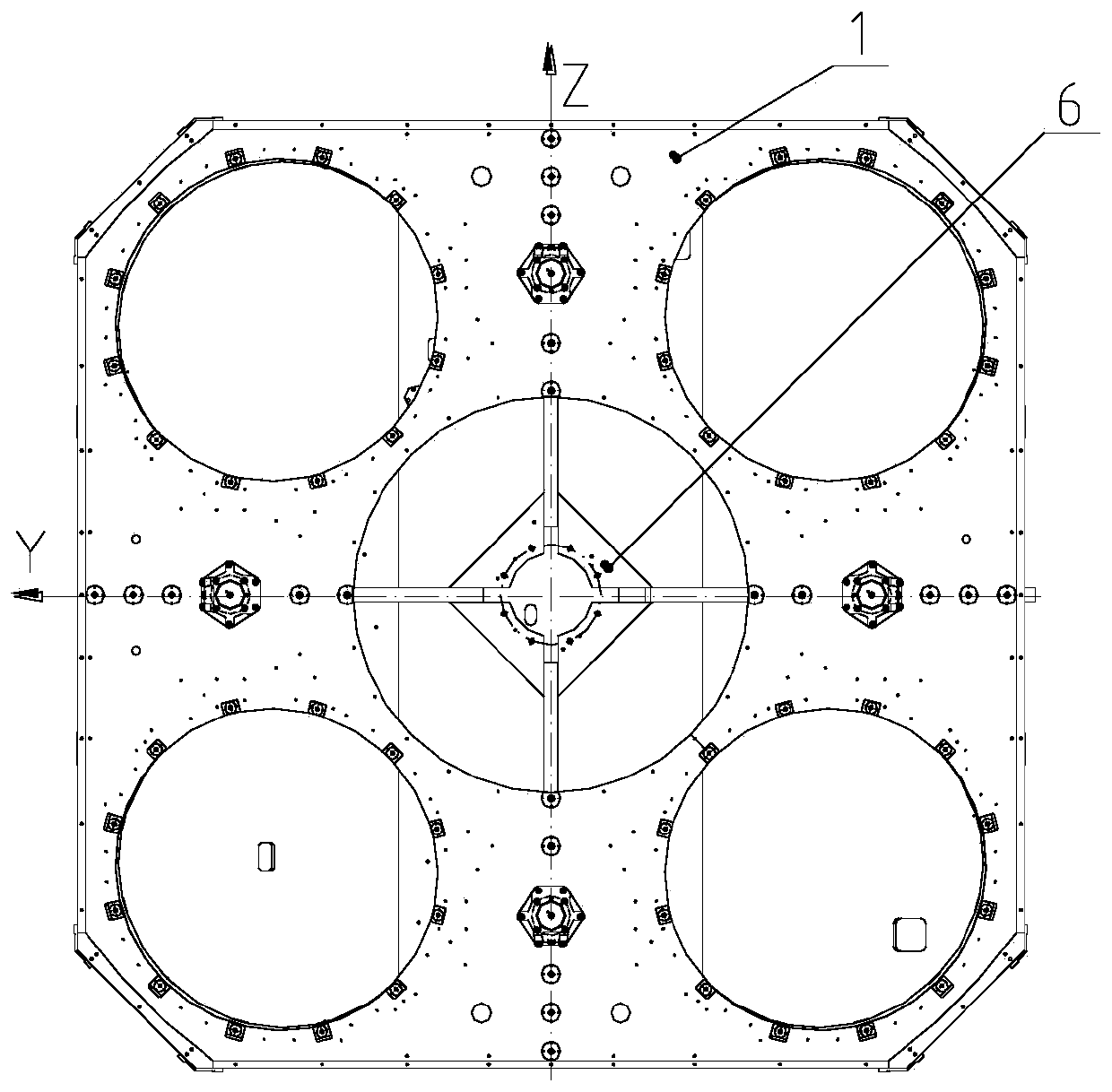

[0029] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0030] A light-weight spacecraft main structure, in order to achieve structural functions with the smallest deck area, it is determined to adopt the structural configuration of octagonal prisms with convex top and bottom, which effectively reduces the structural weight at the overall layout level. After the overall layout of the structure is determined, the load transfer path of the whole structure is optimally designed in combination with the equipment distribution and bearing requirements, and it is determined that the structure on the main load transfer path is composed of an upwardly convex top plate, four partitions and a downwardly convex bottom plate. The load transmission path is shortened, the height of the center of mass is reduced, the structural weight is reduced, and the structural rigidity and bearing capacity are improved.

[0031] Thus, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com