Novel environment-friendly noise-free quick surrounding and pulling device for water conservancy building construction

A noise-free, new device technology, applied in construction, building structure, on-site preparation of building components, etc., can solve the problems of low work efficiency, slowness, high labor intensity of operators, etc., to improve work efficiency and reduce labor costs. The effect of lowering the strength and tightening the mold body is convenient and fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

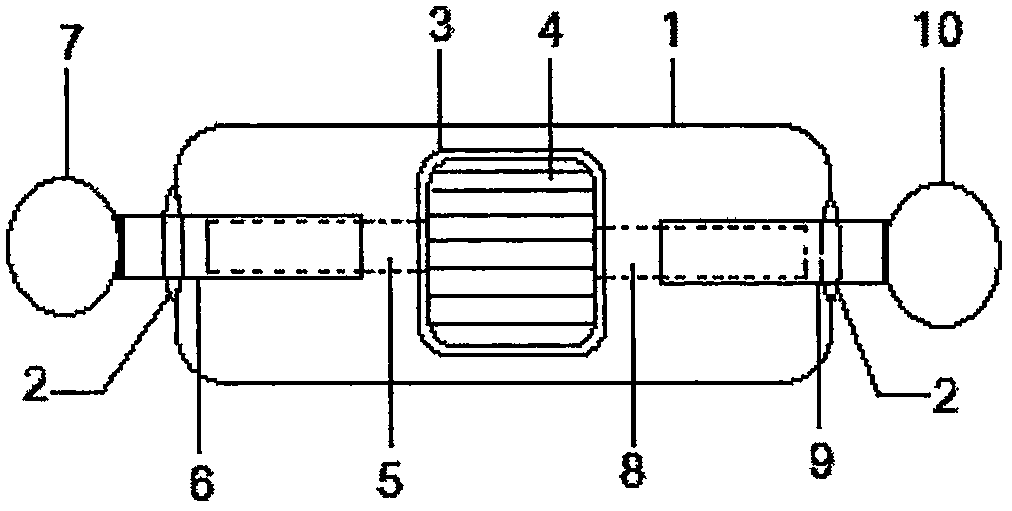

[0008] figure 1 Shown the structure of the present invention, below in conjunction with figure 1 To further illustrate the present invention, the figure 1 Sliding holes 2 are set at both ends of the tensioning tube 1, and a square opening 3 is set in the middle, and an internal force gear 4 is set in the square opening 3, and a reverse full-wire shaft 5 is set at one end of the internal force gear 4, and a reverse full-wire The shaft 5 is equipped with a reverse internal full wire tensioning sleeve 6, the outer end of the reverse internal full wire tensioning sleeve 6 is provided with a first circular pull ring 7, and the other side of the internal force gear 4 is provided with a forward full wire Shaft 8, forward full wire through shaft 8 is provided with positive inner full wire tightening sleeve 9 outside, and the outer end of forward inner full wire tension sleeve 9 is provided with a second circular pull ring 10 .

[0009] The use process of the present invention is: wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com