Solar conveyor

A technology of conveyors and solar energy, applied in the field of conveyors, can solve the problems of high power consumption, waste of energy, and impact on transmission efficiency of conveyors, and achieve the effects of improving photoelectric replacement efficiency, improving absorption capacity, and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

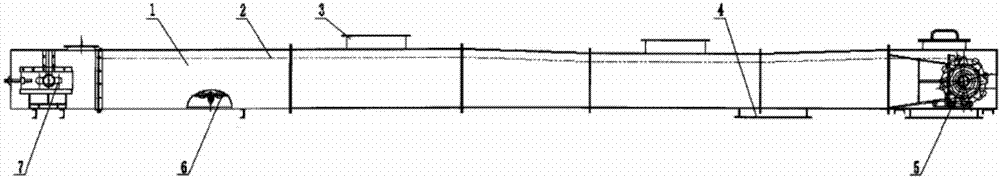

[0014] As shown in the drawings: a solar conveyor, which includes a shell part and a transmission part that plays a role in transmission, the shell part includes a casing 1, a chain guide rail 2, a material inlet 3 and a material discharge port 4, so The top of the casing 1 is provided with a material inlet 3, the bottom of the casing 1 is provided with a discharge port 4, the inside of the casing 1 is provided with a chain guide rail 2, and the transmission part includes a driving device 5, a scraper chain 6 and Tensioning device 7 , the driving device 5 is installed at one end of the casing 1 and connected with the scraper chain 6 , and the tensioning device 7 is installed at the other end of the casing 1 .

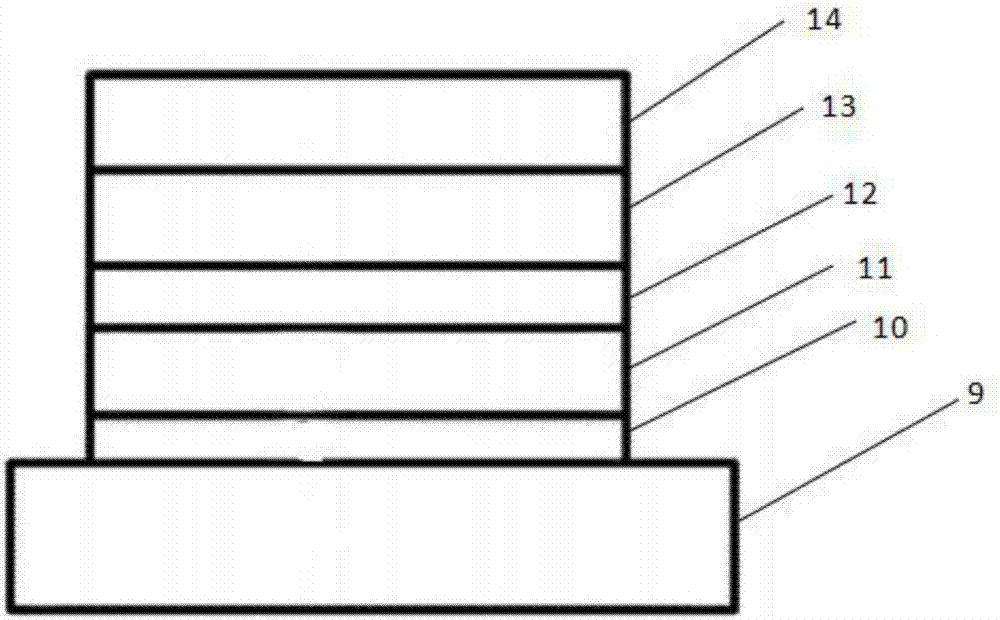

[0015] The surface of the casing is wrapped with a layer of copper indium gallium selenid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com