Pressure relief structure for offshore wind turbine

A technology of wind power generator and pressure relief structure, applied in the direction of valve casing structure, engine components, mechanical equipment, etc., can solve the problems of low working efficiency, inconvenience, and inability to complete pressure relief, so as to improve the efficiency of pressure relief and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

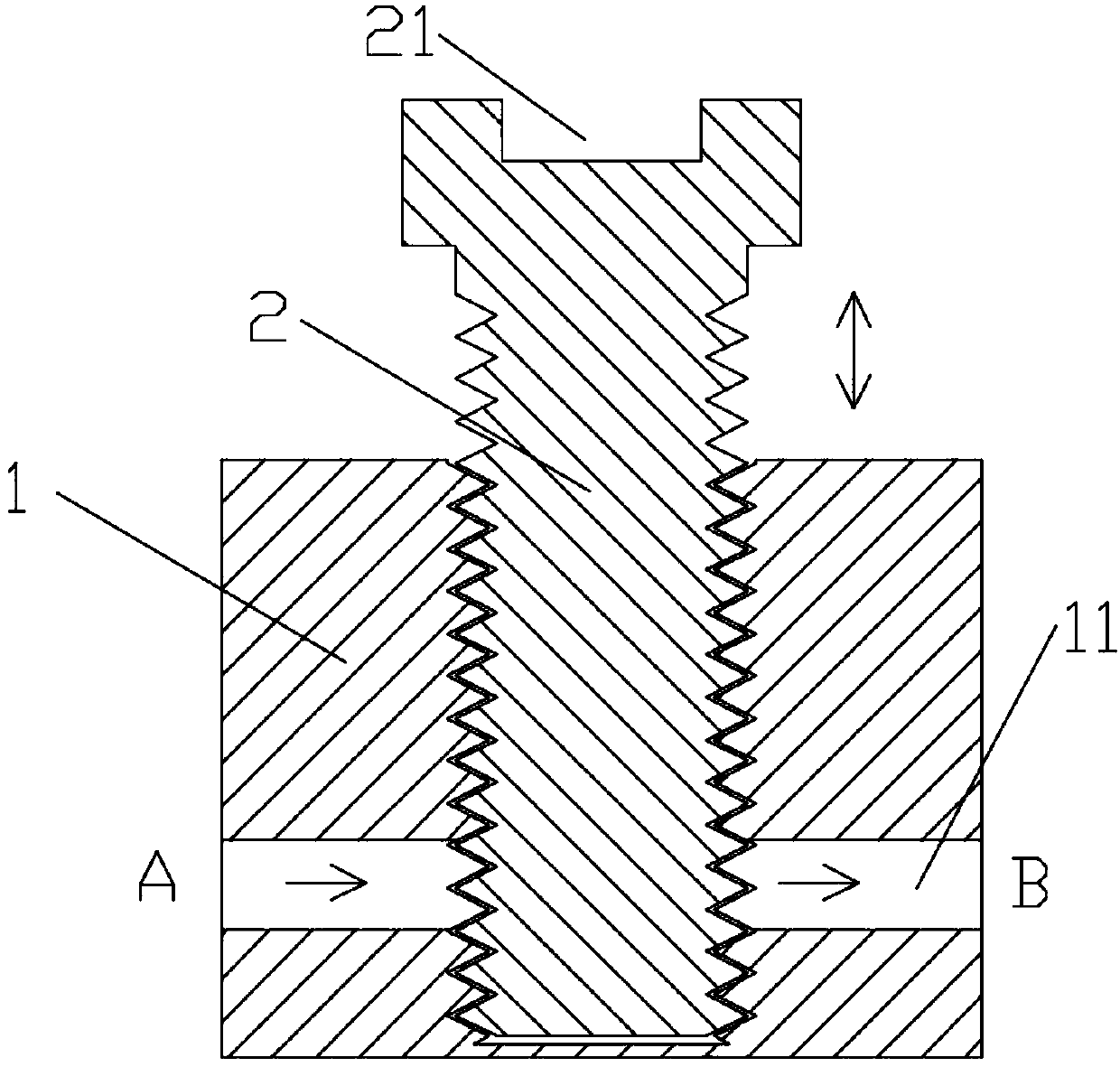

[0034] In order to achieve the purpose of the present invention, as shown in the figure, an embodiment of the present invention is: a pressure relief structure for offshore wind power generators, including:

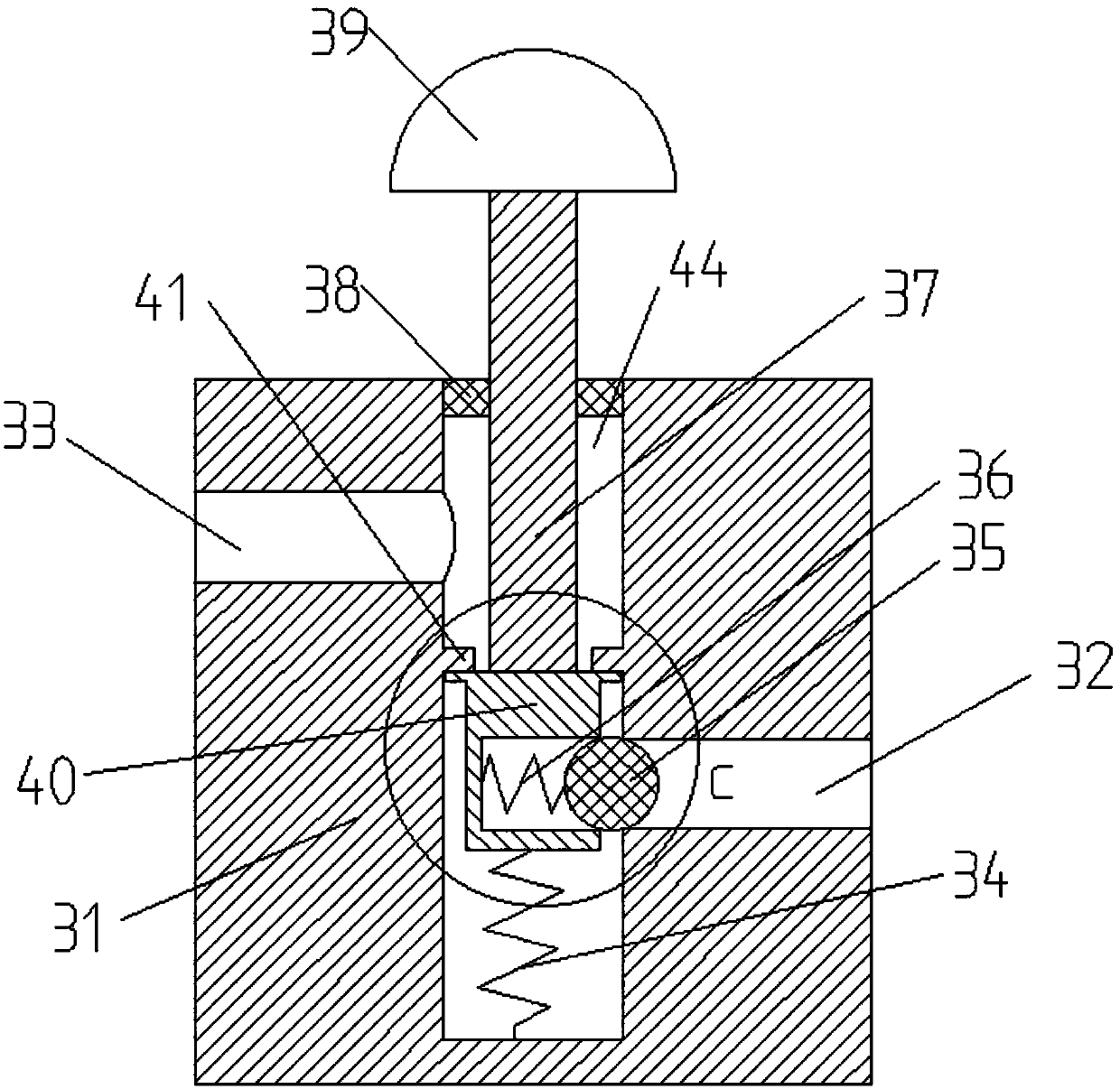

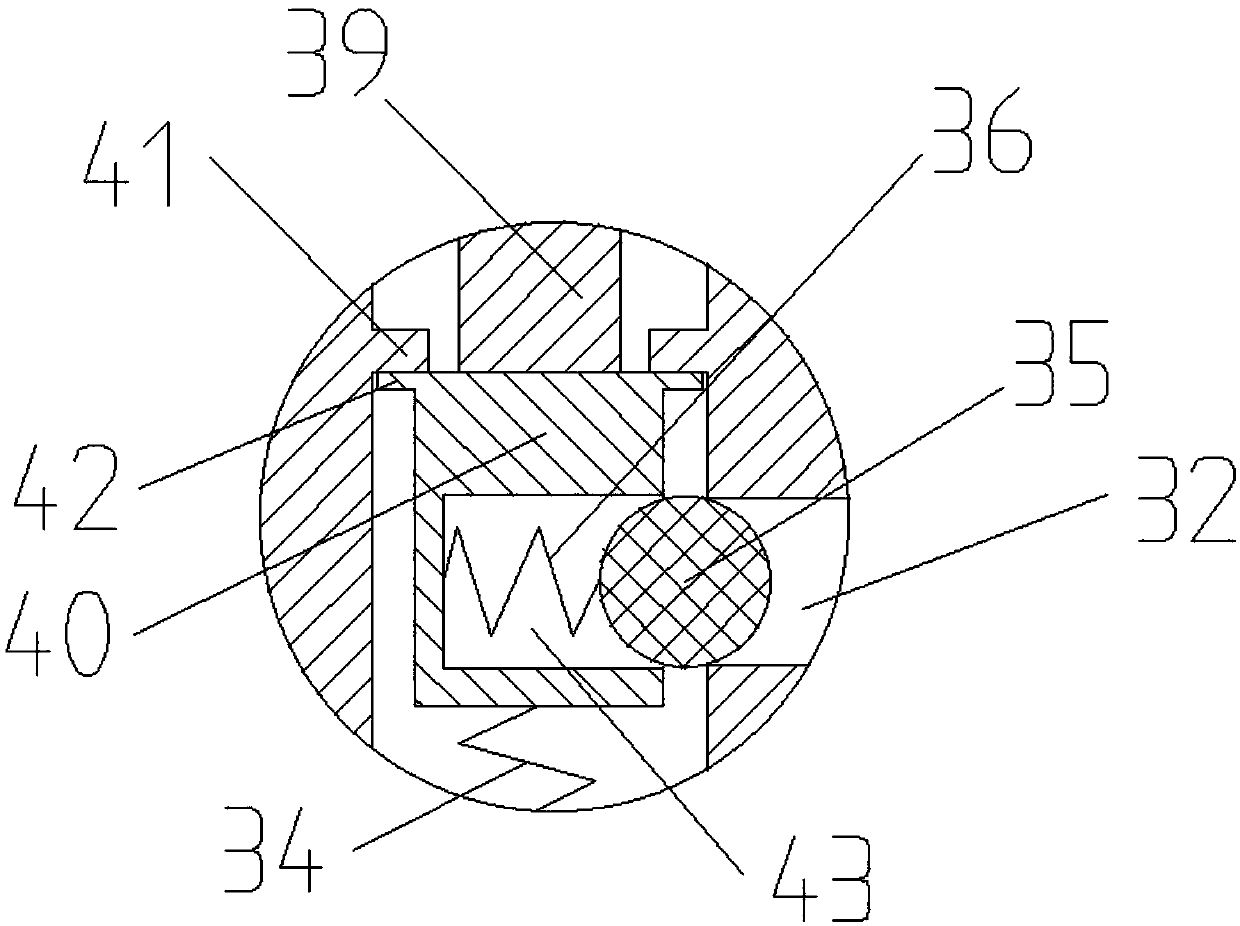

[0035] The valve body 31 has an oil inlet 33 and an oil outlet 32 on both sides of the valve body 31. A blind hole 44 is provided in the middle of the valve body 31. The height of the oil inlet 33 is higher than that of the oil outlet 32. , the normal circulation of the pressure relief passage can be guaranteed, and the backflow phenomenon can be avoided. The oil inlet 33, the blind hole 44 and the oil outlet 32 form a pressure relief passage, and the inner wall of the blind hole 44 is provided with a limit stopper 41. 41 is located between the oil outlet 32 and the oil inlet 33 in the vertical direction;

[0036] Slide bar 37, slide bar 37 moves up and down along the axis of blind hole 44, is provided with T-shaped slide block 40 below slide bar 37, and T-shaped sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com