Gas pipe joint for gas stove

A technology for gas pipe joints and gas stoves, which is applied in the direction of pipes/pipe joints/fittings, sleeves/sockets, passing components, etc., which can solve problems such as locking crooked joints, ineffective tightening, and gas leakage, so as to avoid swinging and Gas leakage, avoiding the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in further detail by specific embodiment now in conjunction with accompanying drawing:

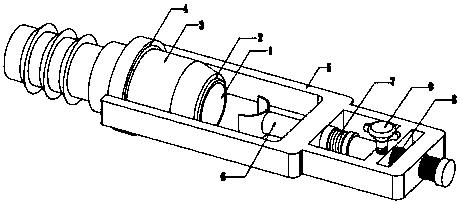

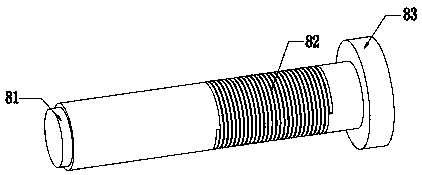

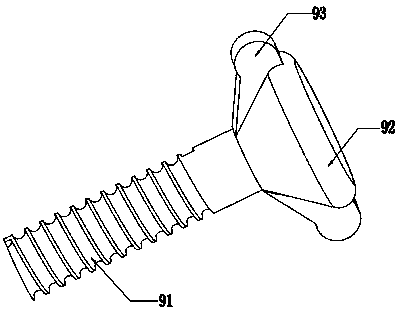

[0030] Such as Figure 1 to Figure 12 As shown, a gas stove gas pipe joint, the gas stove gas pipe joint includes a gas pipe (1), a front sealing ring (2), a sealing joint (3), a middle sealing ring (4), and a push rod support frame (5) , ejector rod (6), ejector rod spring (7), power rod (8), rotating rod (9); the air pipe (1) is cylindrical as a whole; the front sealing ring (2) is set on the sealing The inner side of the front of the joint (3); the intermediate sealing ring (4) is set at the limit block (34) of the intermediate sealing joint of the sealing joint (3); ) is connected to the sealing joint (3); the ejector rod (6) is installed in the ejector rod support frame (5); the ejector rod spring (7) is installed in the ejector rod (6) and Between the power rods (8); the rotating rod (9) is installed on the ejector rod support frame (5).

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com