A surface acoustic wave filter chip packaging structure

A chip packaging structure and surface acoustic wave filtering technology, applied in impedance networks, electrical components, etc., can solve the problems of thermal expansion of substrates, affecting the characteristics of electronic components, and brittleness of metal bumps and substrates. The effect of improving product reliability and improving manufacturing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

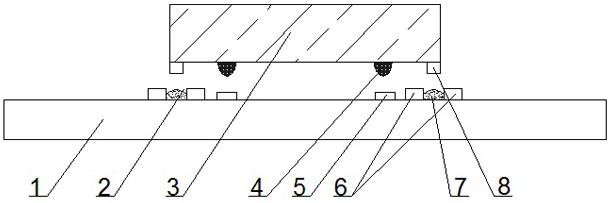

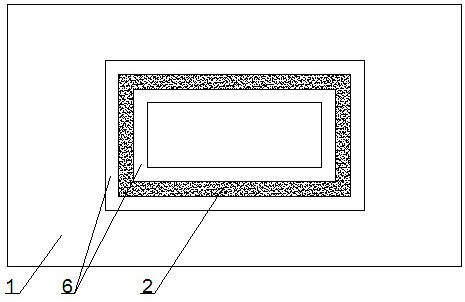

[0026] Such as figure 1 As shown, a surface acoustic wave filter chip packaging structure in this embodiment includes a substrate 1, a trench structure 2 is provided on the surface of the substrate 1, and the trench structure 2 is formed by a substrate circuit 6. Above the substrate 1 A chip 3 is provided, the bottom of the chip 3 is provided with a conductor 4, the chip 3 is electrically connected to the substrate circuit 5 through the conductor 4, a ring of bumps 8 is arranged around the bottom of the chip 3, and the bump 8 is located on the chip 3 the active area and the periphery of the conductor 4, the bump 8 fits with the trench structure 2, thereby forming a cavity structure in the active area of the chip 3, and the periphery of the chip 3 and the trench structure 2 is encapsulated with a plastic encapsulant;

[0027] Further, the bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com