Stabilized concentrated liquid human milk fortifier

A human milk fortifier, liquid technology, applied in the field of improved stabilizer, long-term stable, concentrated liquid human milk fortifier, can solve problems such as limited success, and achieve the effect of reducing volume replacement and reducing the risk of microbial contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The concentrated liquids and corresponding methods of preparation of the present disclosure may comprise, consist of, or consist essentially of the elements and limitations of those described herein and any additional or optional ingredients, components described herein or otherwise useful in concentrated liquids points or limits.

[0050] product form

[0051] Although discussed primarily as concentrated liquid human milk fortifiers, those skilled in the art will recognize that the concentrate compositions described herein may additionally include other concentrated liquid nutritional compositions, which may be suspensions, emulsions, or clear or substantially clear of liquid. The resulting concentrated liquid nutritional composition can be used as an infant, child, toddler and / or adult liquid nutritional composition and / or a pharmaceutical liquid nutritional composition.

[0052] The concentrated liquid human milk fortifiers of the present disclosure have a solids c...

Embodiment 1-4

[0127] In Examples 1-4, a concentrated liquid human milk fortifier can be prepared according to the present disclosure. The ingredients of the Concentrated Liquid Human Milk Fortifier are shown in the table below. All ingredient amounts are listed in pounds per approximately 1000 pound batch unless otherwise specified.

[0128]

[0129] Concentrated liquid human milk fortifiers are prepared by dissolving and combining / blending ingredients into a homogeneous aqueous mixture that is sufficiently heat-treated and aseptically filled for long-term physical and microbiological storage stability.

[0130] To begin the preparation process, the macronutrients (carbohydrates, proteins, fats and minerals) are mixed together with several slurries and water. The blend was subjected to an initial heat treatment and then tested to verify proper nutrient levels. Additional details on this process are provided in the following paragraphs.

[0131] An intermediate aqueous carbohydrate-min...

Embodiment 5

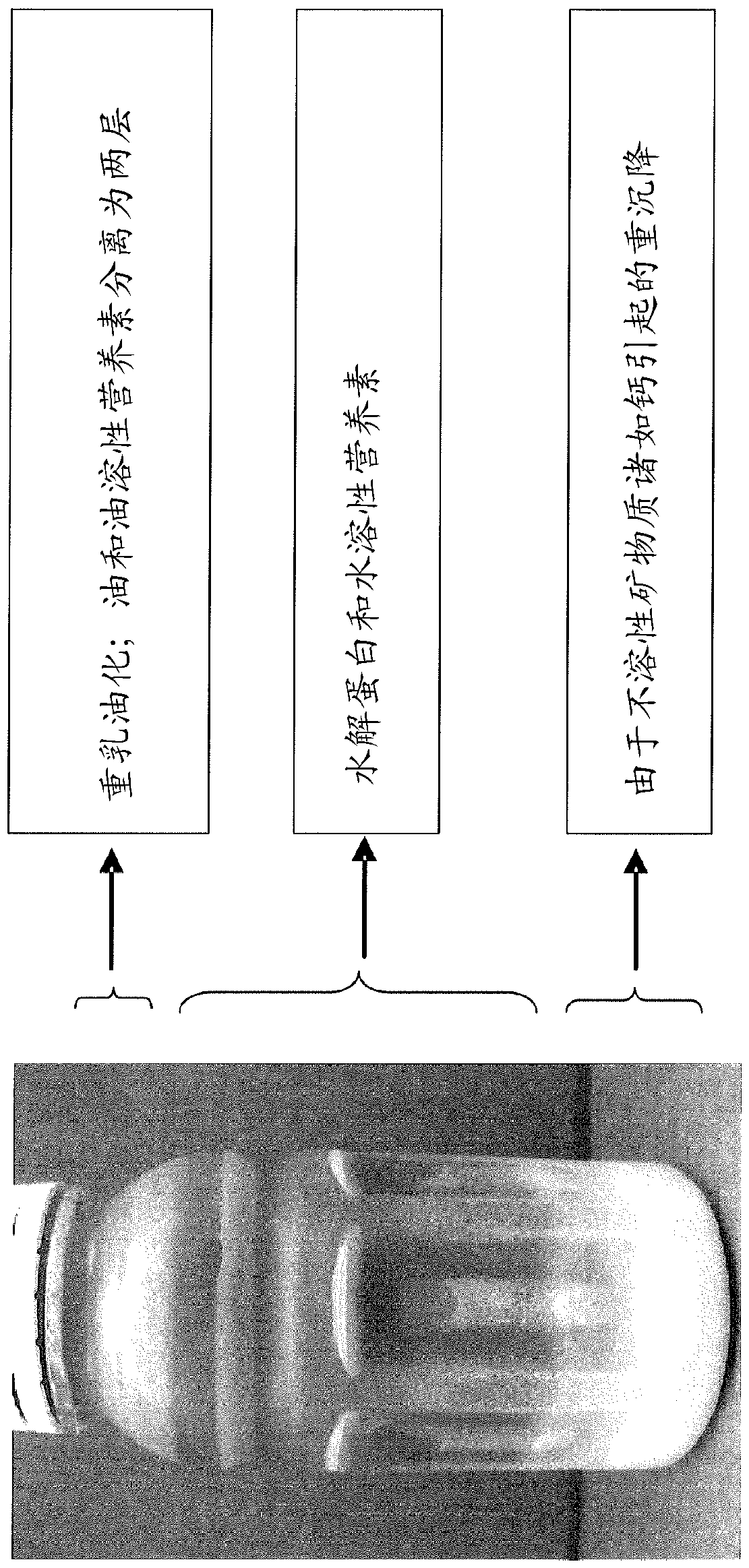

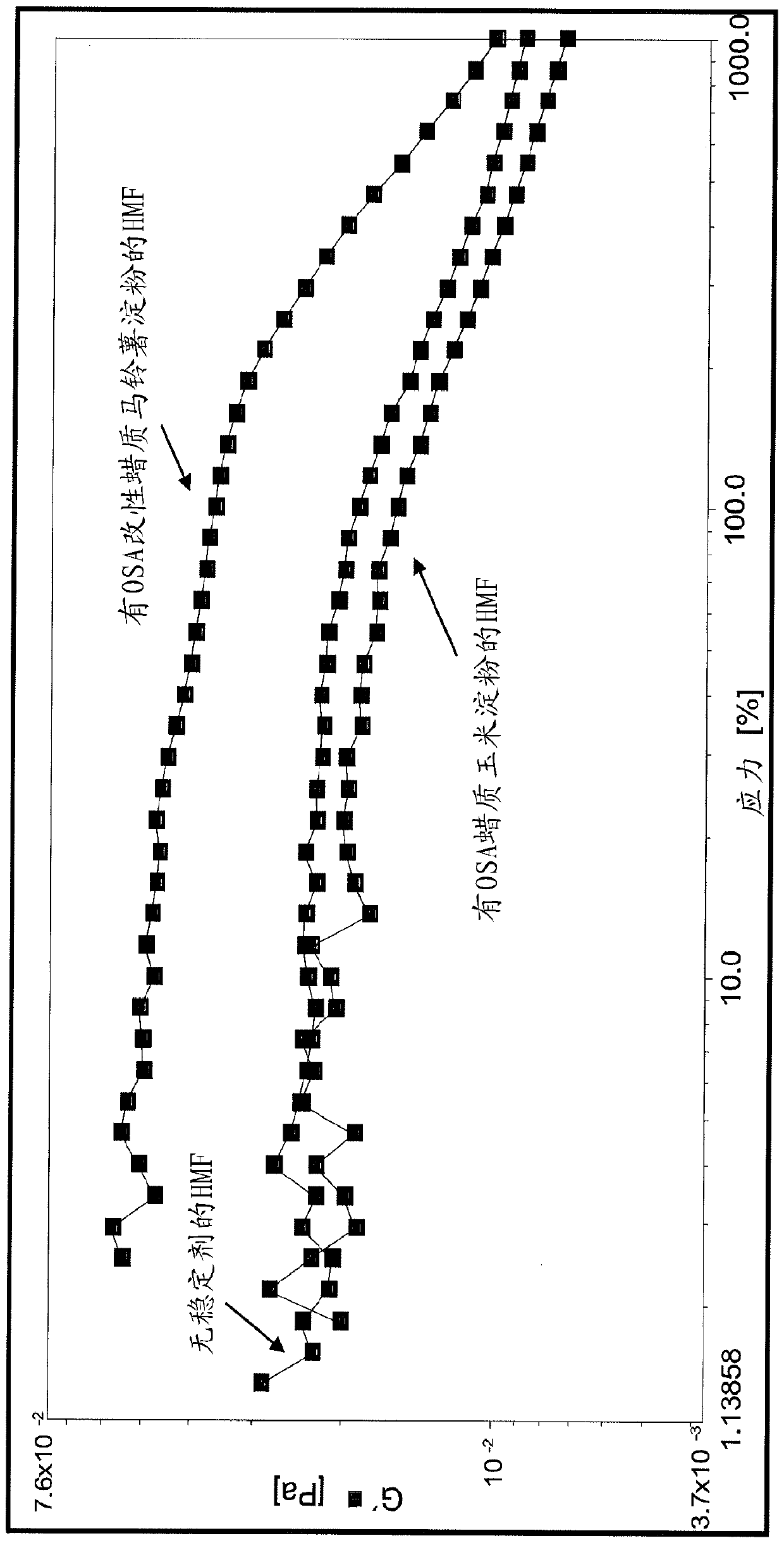

[0140] In this example, OSA-modified waxy potato starch in a concentrated liquid human milk fortifier was analyzed and compared to a control concentrated liquid human milk fortifier without a stabilizer and a concentrated liquid human milk fortifier using OSA-modified waxy corn starch as a stabilizer. Liquid human milk fortifiers for comparison.

[0141] Three samples of liquid human milk fortifier including fully hydrolyzed casein were prepared using a method similar to that described in Examples 1-4: The first sample was a control without added stabilizer. A second sample was prepared that included 1.2% by weight OSA modified waxy corn starch (Uni-Pure® IMF 2332, Ingredion Incorporated (Westchester, IL) Starch Food Innovation, Bridgewater, New Jersey) as a stabilizer. A third sample was prepared which included 1.2% by weight OSA modified waxy potato starch (ELAINE™ MC-160, AVEBE, TheNetherlands) as a stabilizer. The samples were then stored at room temperature for at least ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com