Optical system for LED stage lamp

An optical system and LED light source technology, which is applied in the field of optical systems, can solve problems such as the difficulty of taking into account the uniformity of the spot and the light effect at the same time, and achieve the effect of improving the uniformity of the spot, high light efficiency, and improving the uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

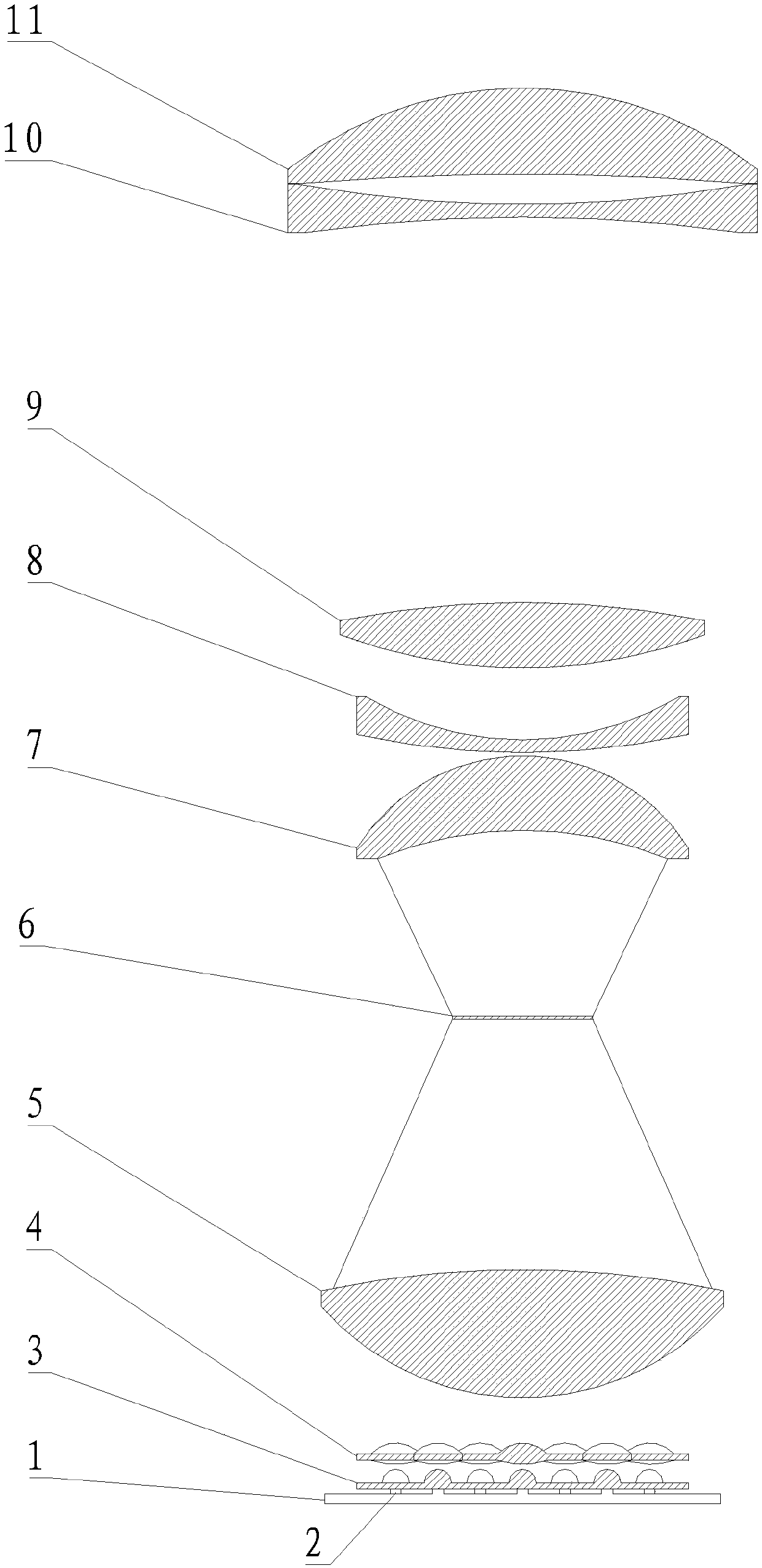

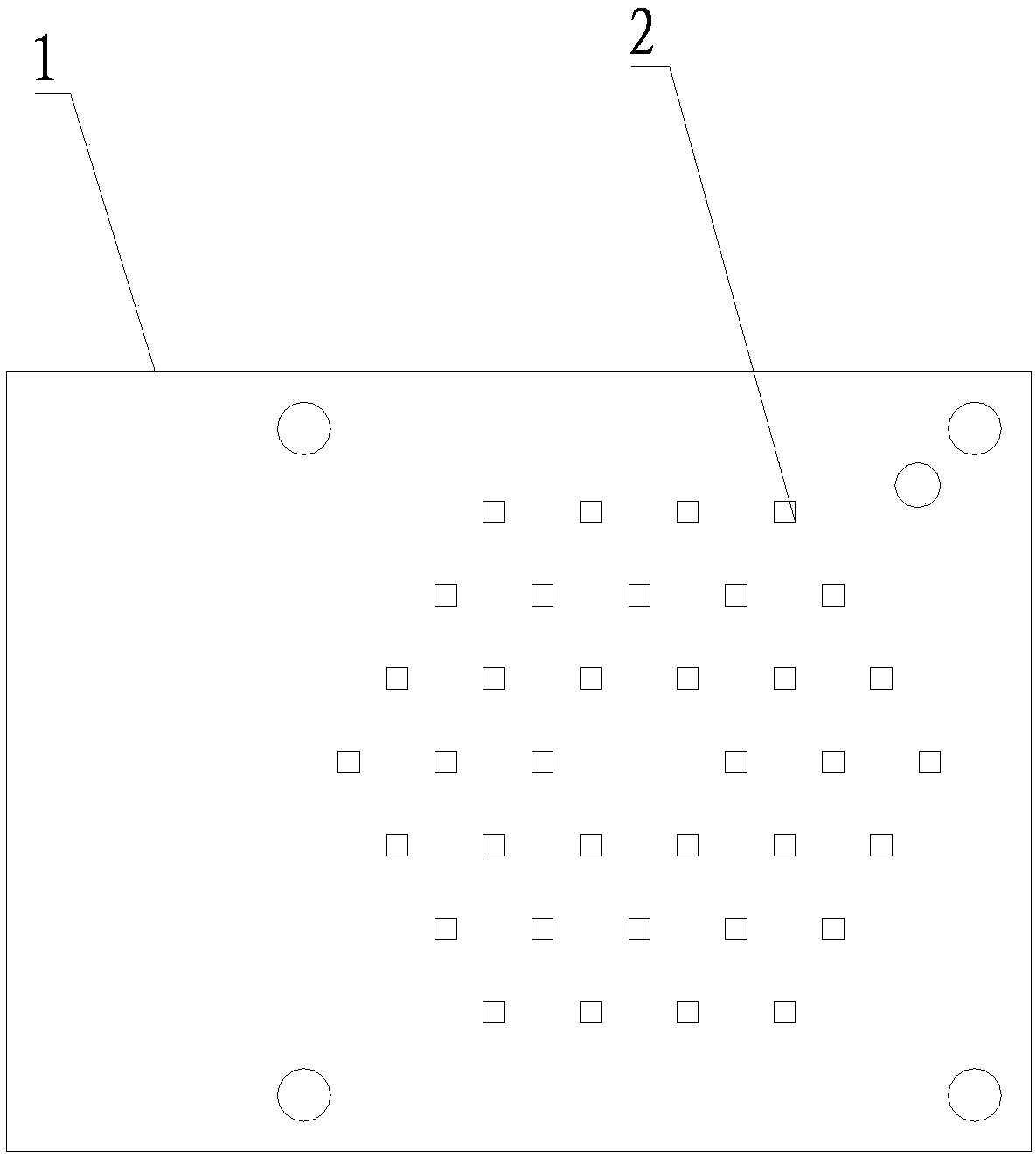

[0030] refer to figure 1 and figure 2 , the number of the LED lamp beads 2 is not less than 18, and no lamp beads are placed in the center of the substrate 1 . In this embodiment, no LED lamp bead 2 is placed at the center of the substrate 1, so that the uniformity of the light spot can be controlled. The greater the number of lamp beads, the more beneficial it is for light mixing. The uneven distribution of light intensity of a single LED light source can be achieved by interfering and superimposing light waves of more light sources and complementing each other to enhance the effect of light mixing and uniform light. Setting the number of 18 is the minimum number required for two hexagonal arrays. If the number is less than 18, it is difficult to increase the power of the optical system, and the second is that the uniformity of the spot will be reduced.

Embodiment 2

[0032] refer to figure 1 and figure 2 The radius of curvature of the light-incident surface of the first lens 12 is 4.5-10.0 mm, the radius of curvature of the light-exit surface is 2-6 mm, and the distance between the first lens 12 and the LED lamp bead 2 is 0.05-0.30 mm. In this embodiment, the distance between the first lens 12 and the LED lamp bead 2 is installed too low, which is not conducive to the installation operation, and the distance is too high, which is not conducive to light collection and affects the light collection efficiency. Therefore, an appropriate distance can be selected within the range of 0.05-0.30 mm according to actual needs. The first lens 12 and the second lens 13 together form a condenser lens group with an effective focal length EFFL value of 3.5mm. The range of curvature radii of the two single lenses depends on the size of the effective focal length. The reason why the effective focal length of the condenser lens group of this program is set...

Embodiment 3

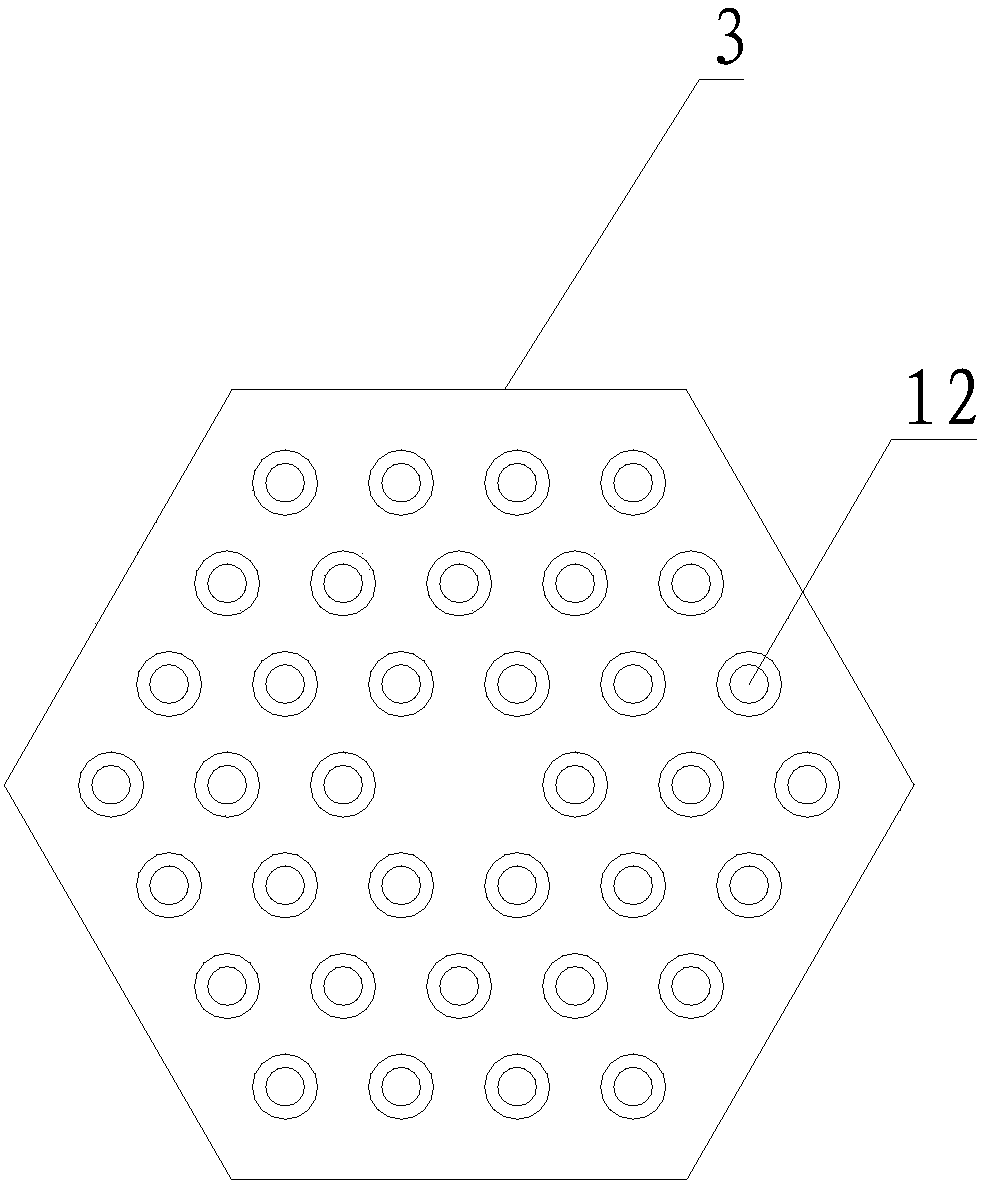

[0034] refer to figure 1 and image 3, the first condenser lens group 3 includes a plurality of first lenses 12; the first lenses 12 are arranged in one-to-one correspondence with the LED lamp beads 2. In this embodiment, the number of first lenses 12 is determined by the number of LED lamp beads 2, and each LED lamp bead 2 is provided with a corresponding first lens 12. After focusing, improve the uniformity of single beam.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap