Asphalt pavement structure analysis equivalent method based on pavement material modulus stress and strain dependent model

A technology for asphalt pavement and pavement materials, which is applied in the direction of applying stable tension/pressure to test the strength of materials, which can solve the diversity of structural layer modulus test methods and the uncertainty of values, and it is difficult to accurately and objectively evaluate the pavement structure. Problems such as real stress state, unfavorable new pavement design and in-service pavement life evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] Taking an asphalt pavement structure as an example, the equivalent method for the analysis of asphalt pavement structure based on the pavement material modulus stress (strain) dependent model is described. The specific steps are as follows:

[0069] Step 1. Select the asphalt pavement structure form, material type and calculation and analysis system to be analyzed.

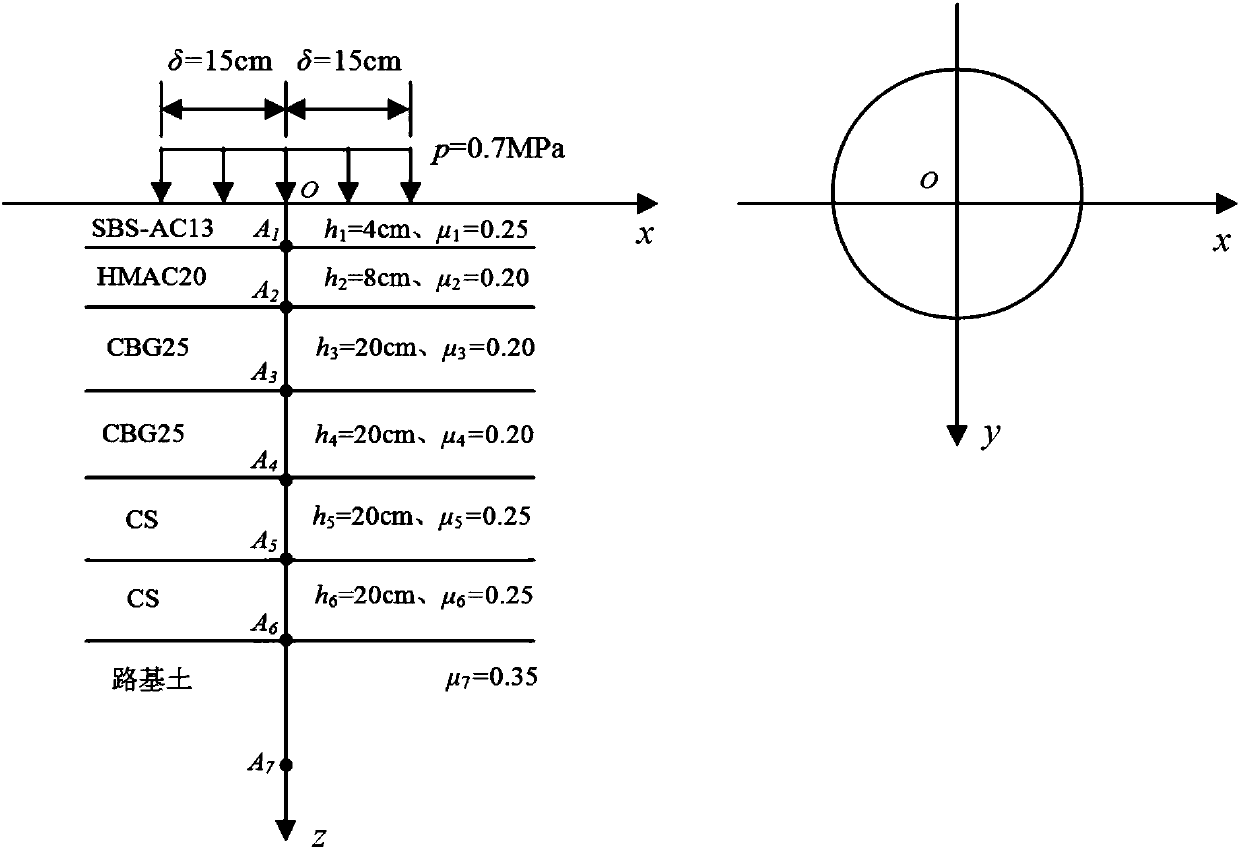

[0070] (1) Select as figure 1 The long-life asphalt pavement structure with semi-rigid base is shown as the pavement structure to be analyzed. The structure has 7 layers, and the pavement thickness and materials from top to bottom are: 4cm SBS-AC13 asphalt layer, 8cm HMAC20 asphalt layer, 20cm cement stabilized macadam CBG25 semi-rigid base, 20cm cement stabilized macadam CBG25 semi-rigid base, 20cm Cement-stabilized soil CS semi-rigid base, 20cm cement-stabilized soil CS semi-rigid base, road base.

[0071] (2) The Poisson's ratio of SBS-AC13 and cement-stabilized soil CS is 0.25, the Poisson's ratio of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com