Light emitting diode

A light-emitting device and light-emitting element technology, which is applied in the direction of electrical components, electric solid-state devices, circuits, etc., can solve the problems of unsatisfactory brightness and difficulty in providing full-circle light color rendering, so as to improve performance and reliability, improve color rendering, Improve the falloff effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

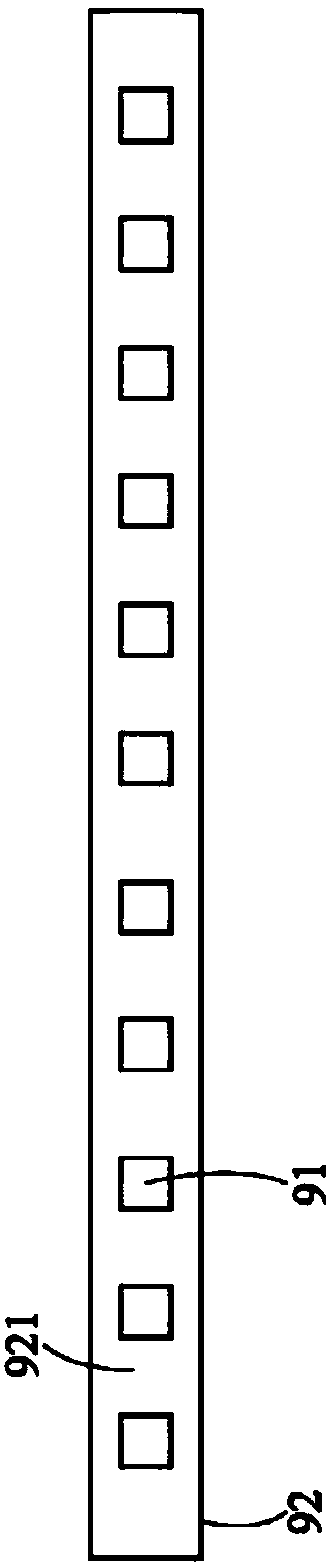

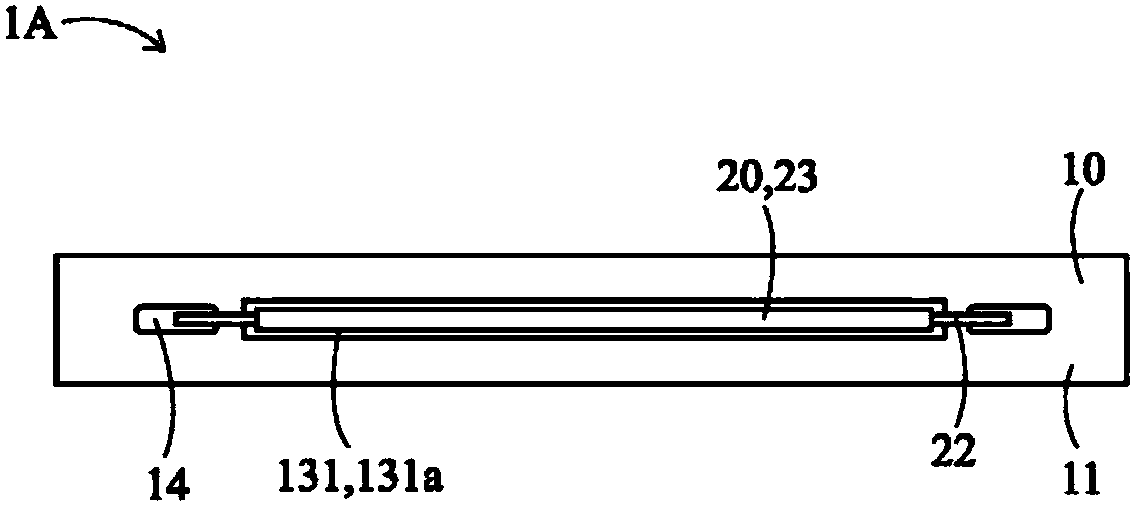

[0056] see Figure 2A to Figure 3A As shown, it is the top view, bottom view and front view of the light emitting device according to the first preferred embodiment of the present invention. The light emitting device 1A includes a substrate 10 and at least one LED light emitting element 20 , and the technical content of each element is described as follows.

[0057] The substrate 10 can be a printed circuit board (PCB), which includes a first surface 11 , a second surface 12 , at least one light-transmitting region 13 and at least two metal pads 14 . The first surface 11 and the second surface 12 are arranged opposite to each other, and both are the light-emitting surfaces of the light-emitting device 1A, which means that light can be emitted from the first surface 11 and the second surface 12 in two opposite directions away from the substrate 10 (ie, the normal direction). , so that the light-emitting device 1A can provide a full-circle light effect.

[0058] At least one l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com