Testing device and method for calibrating response frequency of shear sensitive liquid crystal coating

A technology of liquid crystal coating and response frequency, which is applied in the field of test devices for calibrating the response frequency of shear-sensitive liquid crystal coatings, can solve problems such as difficulty in calibrating the response frequency of shear-sensitive liquid crystal coatings, and achieves simple structure, low equipment requirements, and convenience. The effect of disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

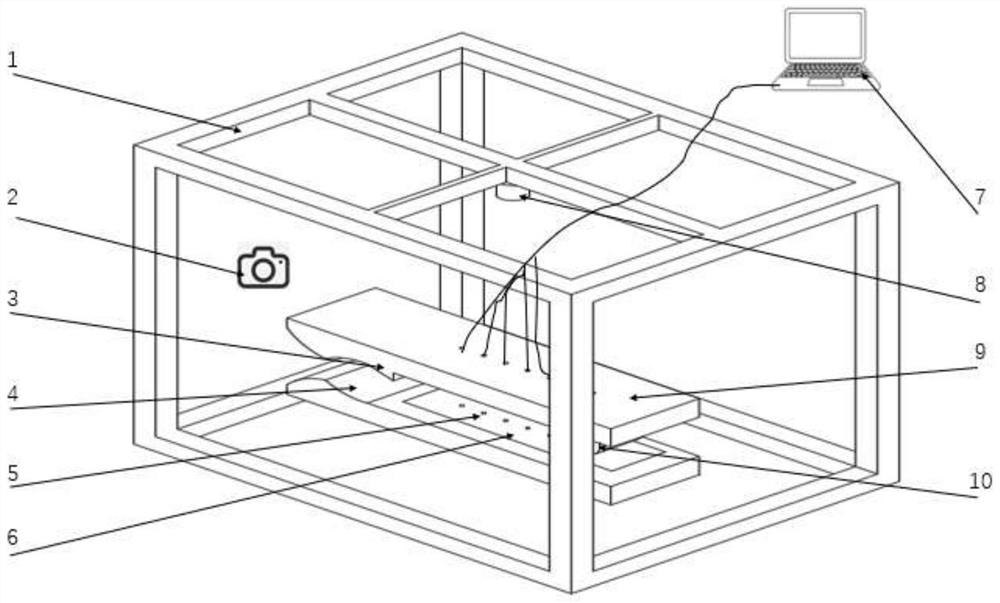

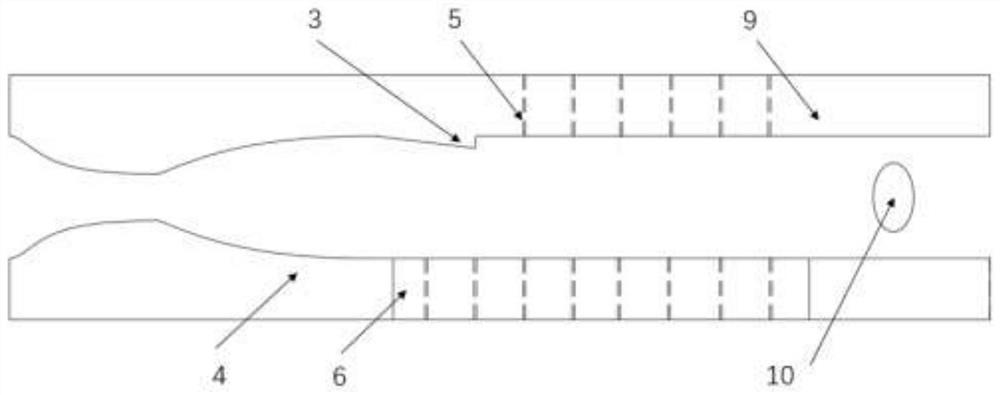

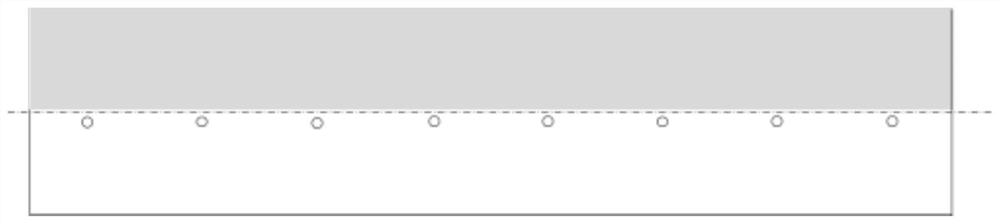

[0034] refer to figure 1 As shown, a test device for calibrating the response frequency of the shear-sensitive liquid crystal coating flow field of the present invention includes: a support 1, a high-speed camera 2, a wedge 3, a Laval nozzle 4, a high-frequency dynamic pressure sensor 5, and The disassembled lower wall plate 6, dynamic pressure acquisition system 7, light source 8, equal straight pipe 9, rotating cam 10; wherein,

[0035] The supersonic gas flow at the outlet of the Laval nozzle 4 generates an incident shock wave at the leading edge of the wedge 3 and extends to the lower wall of the straight pipe 9, interacting with the turbulent boundary layer to produce a symmetrical flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com