Blue ceramic pigment and preparation method thereof

A ceramic pigment and blue technology, which is applied in the field of high-temperature resistant pigments, can solve the problems of reducing the blueness of pigments and reducing the coloring ability of pigments, and achieve the effect of improving color rendering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A preparation method of blue ceramic pigment, comprising the following steps:

[0031] S1: Mix Mg, Al, Si, Co raw materials and mineralizers uniformly according to the stoichiometric ratio. The raw materials of Mg, Al, Si, and Co are oxides, nitrates, carbonates, Acetate, the mineralizer is one or a combination of NaCl, KCl, LiCl, sodium carbonate, lithium carbonate, potassium carbonate, calcium oxide, and the addition of the mineralizer is Mg, Al, Si, Co raw materials 0-20% of the total weight;

[0032] S2: calcining the mixed powder, the calcination temperature is set to 1100-1500°C, and the calcination time is 1-10h;

[0033] S3: The obtained product is pulverized again, washed with water, and the washing times are 1-5 times;

[0034] S4: the washed product is dried to obtain the final product, and the drying temperature is set at 40-150°C.

Embodiment 1

[0035] Example 1: Mg 1.2 Al 1.6 Si 0.2 Co 0.05 O 4 preparation

[0036] Accurately weigh 2.358g MgO, 3.976g Al 2 O 3 ,0.586g SiO 2 ,1.091g Co(NO 3 ) 2 , put it into a mortar, add an appropriate amount of anhydrous ethanol, grind and mix evenly. The ground mixed powder was placed in a corundum crucible and dried at 80°C for 2 hours. The dried samples were transferred to a muffle furnace, calcined at 800°C for 3 hours, cooled to room temperature and then ground and mixed uniformly. It was calcined again at 1400°C for 5 hours. After cooling, it was ground into fine powder, washed with water, and dried at 80°C for 12 hours to obtain the final product.

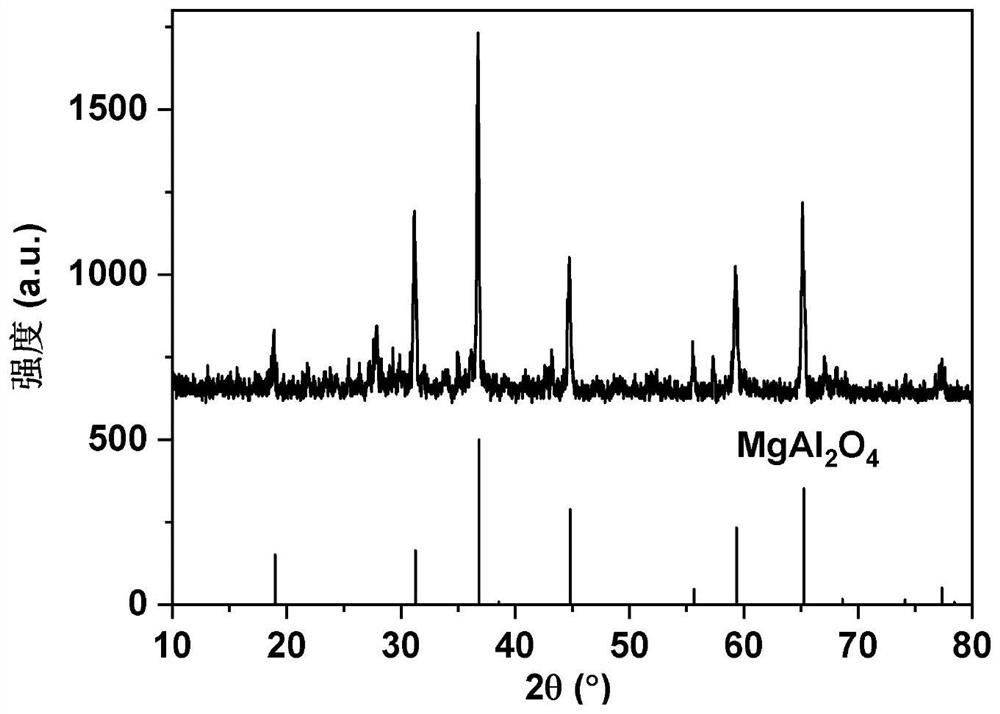

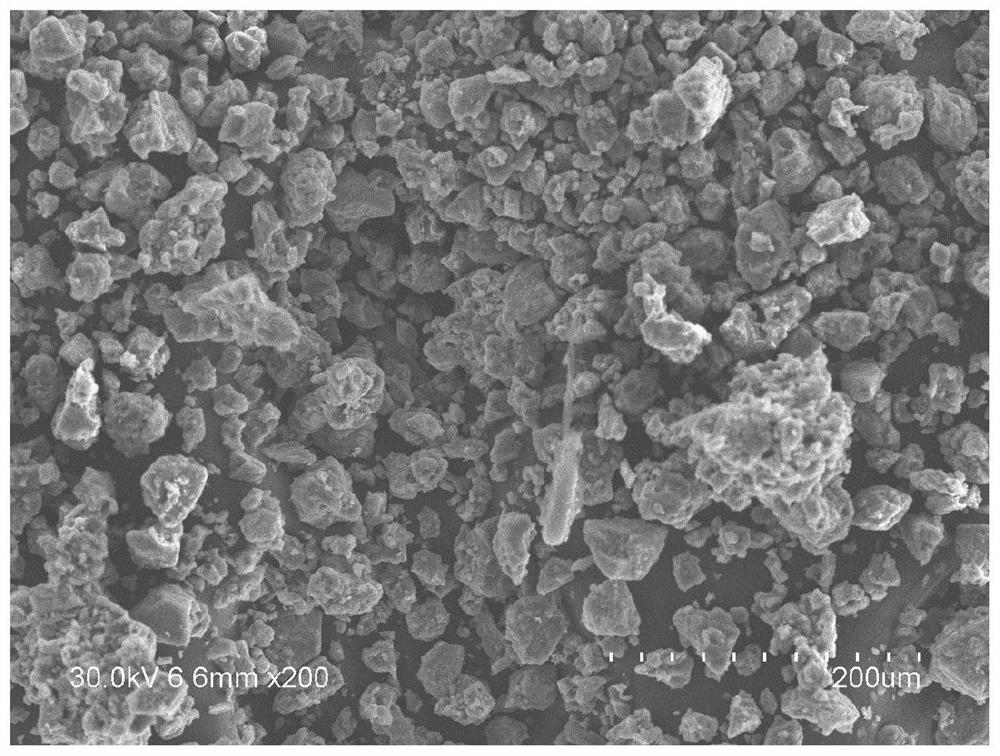

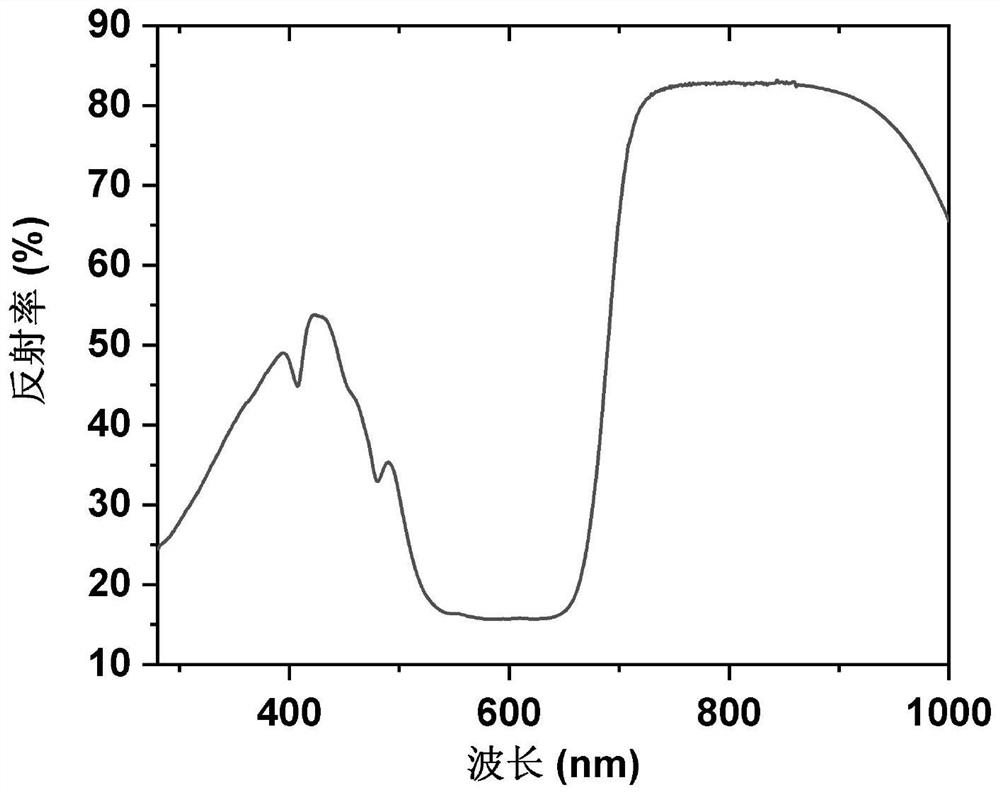

[0037] figure 1 Mg calcined at 1400°C 1.2 Al1.6 Si 0.2 Co 0.05 O 4 X-ray powder diffraction (XRD) patterns of ceramic pigments, such as figure 1 As shown, the main crystal phase of the obtained sample is MgAl 2 O 4 Spinel phase. figure 2 Mg calcined at 1400°C 1.2 Al 1.6 Si 0.2 Co 0.05 O 4 SEM photos of ce...

Embodiment 2

[0038] Example 2: Mg 1.4 Al 1.2 Si 0.4 Co 0.05 O 4 preparation

[0039] Accurately weigh 2.751g MgO, 2.982g Al 2 O 3 , 1.172g SiO 2 , 1.091g Co(NO 3 ) 2 , put it into a mortar, add an appropriate amount of anhydrous ethanol, grind and mix evenly. The ground mixed powder was placed in a corundum crucible and dried at 80°C for 2 hours. The dried samples were transferred to a muffle furnace, calcined at 800°C for 3 hours, cooled to room temperature and then ground and mixed uniformly. It was calcined again at 1400°C for 5 hours. After cooling, it was ground into fine powder, washed with water, and dried at 60°C for 24 hours to obtain the final product. Tested by Konica Spectrophotometer (CM-5), the chromaticity parameters of the sample are L=44.78, a=4.43, b=-30.62.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com