Special rope overline device for power grid

A wire-passing device and rope technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of difficulty in crossing obstacles, rope damage, etc., and achieve the effect of reducing labor intensity, improving work efficiency and good use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

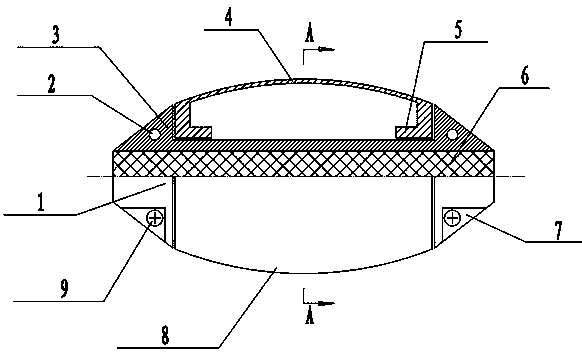

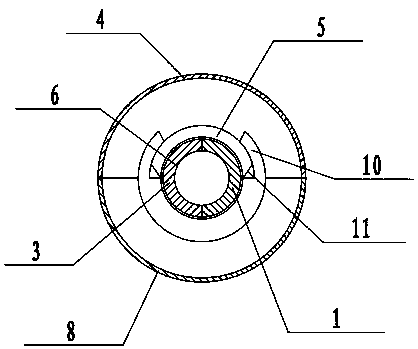

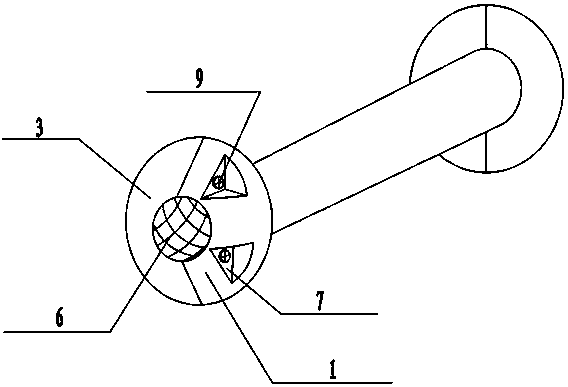

[0016] Such as figure 1 , figure 2 , image 3 , Figure 4 A special rope threader for power grids shown includes a fixed sleeve and a rotating roller. The fixed sleeve is arranged horizontally, and the rotating roller is arranged on the outer circle of the middle part of the fixed sleeve; the fixed sleeve is an I-shaped wheel structure. The front half bushing 1, the rear half bushing 3 and the fixing bolt 9 are composed. The middle of the front half bushing 1 is a horizontal semi-cylindrical body, the front part is an arc surface, and the rear part is a plane. The two ends of the front half bushing 1 are arranged symmetrically. A half-cone is provided, and the front part of the half-cone on both sides is provided with a concave bolt platform 7, and the bolt platform 7 is provided with a bolt through hole. Fixed groove 6, the inner surface of the fixed groove 6 is provided with a textured texture, which can increase the friction force during fixing and prevent the fixed sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com