Hybrid stepping motor with U-shaped permanent magnets embedded into stator

A stepping motor and permanent magnet technology, applied in the direction of magnetic circuit shape/style/structure, electrical components, electromechanical devices, etc., can solve the problems of low utilization rate of permanent magnets, difficult maintenance and replacement, and high processing difficulty, and achieve the goal of using permanent magnets. The effect of high rate, not easy to demagnetize, and large torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0024] The present invention will be further described below in conjunction with the drawings and embodiments.

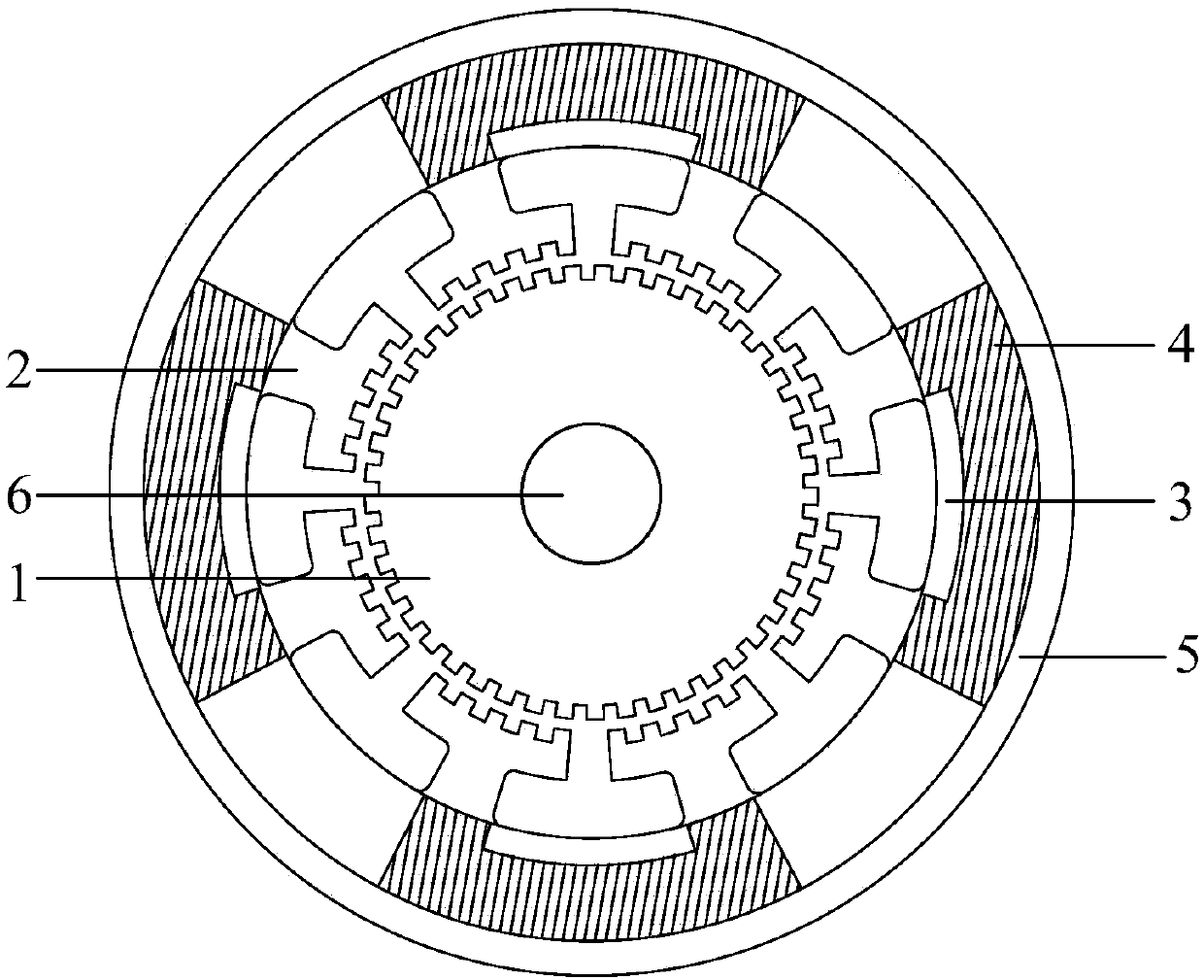

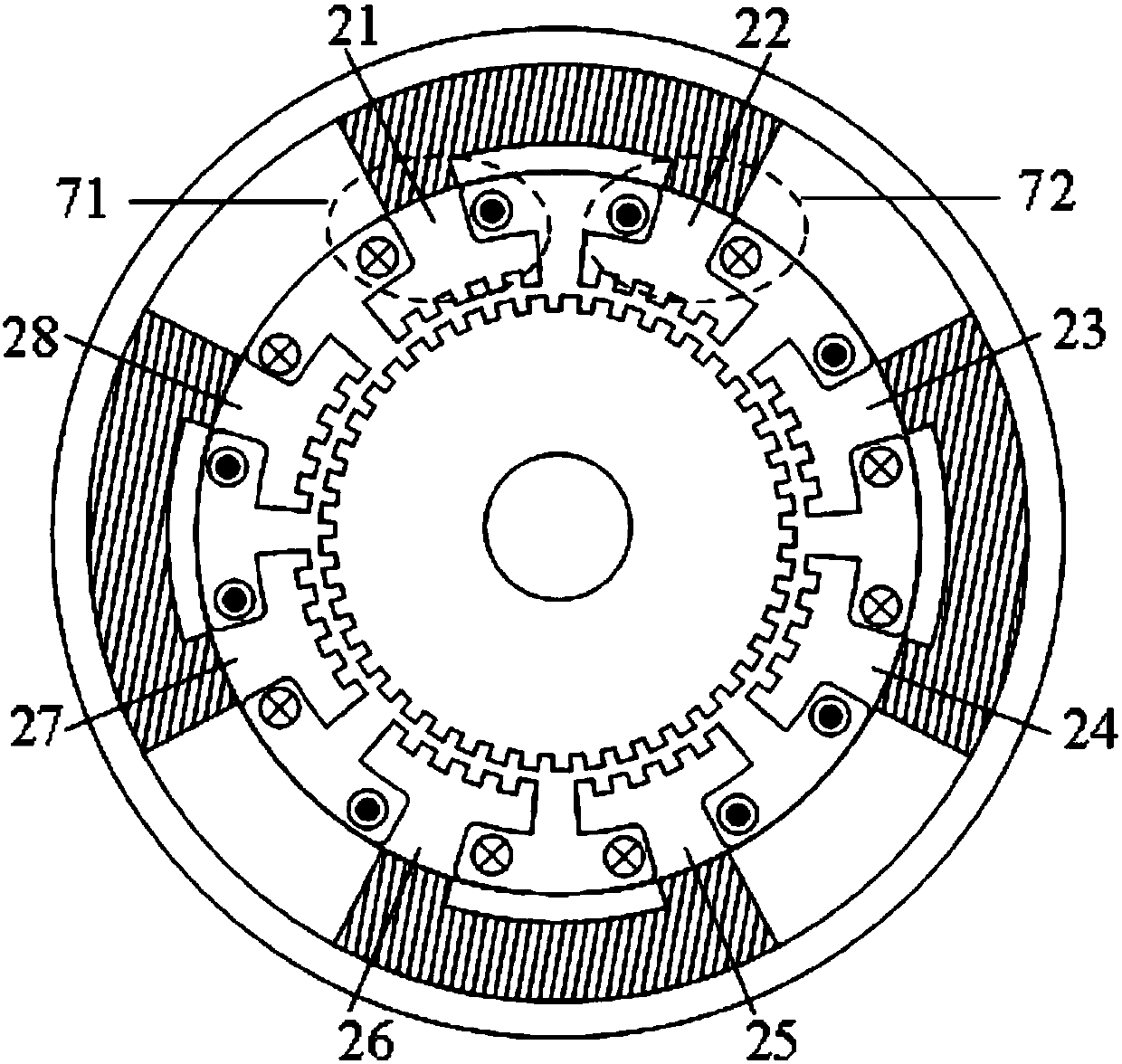

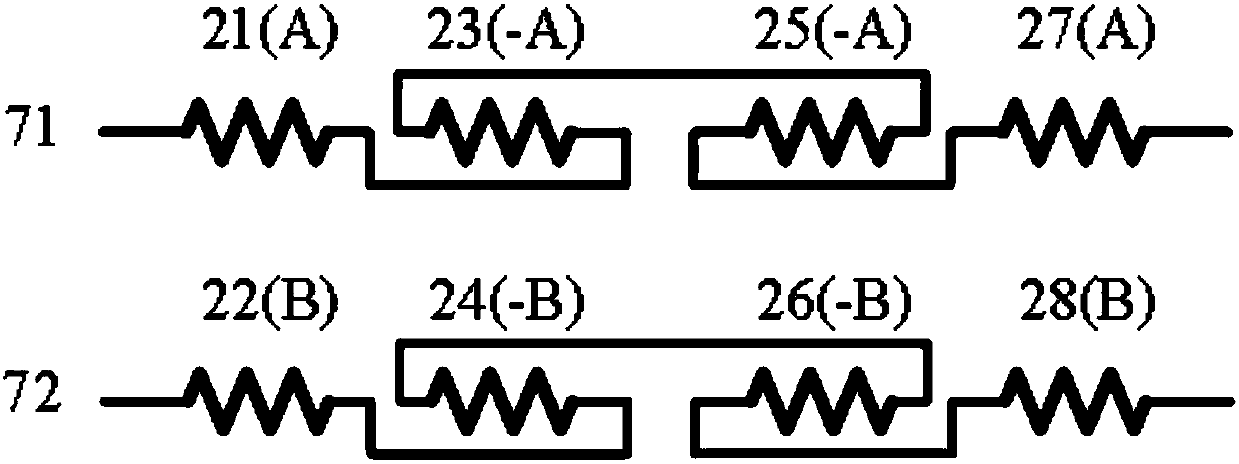

[0025] The present invention is a hybrid stepping motor with U-shaped permanent magnets embedded in the stator, such as figure 1 with 2 As shown, the stator is composed of stator magnetic poles 2, insulation 3, permanent magnets 4, stator coil A-phase winding 71 and stator coil B-phase winding 72. 8 stator magnetic poles 2, which are represented in turn as first stator magnetic pole 21, second stator magnetic pole 22, third stator magnetic pole 23, fourth stator magnetic pole 24, fifth stator magnetic pole 25, sixth stator magnetic pole 26, and seventh stator magnetic pole 27 and the eighth stator magnetic pole 28, the pole shoes of each stator magnetic pole 2 are distributed with 5 small teeth with the same pitch as the rotor teeth, and the pole shoes of each stator magnetic pole 2 are installed with a phase stator winding. The rotor is composed of a laminated rotor c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com