An automatic oil immersion mechanism for cylinder sleeve hardware

A hardware and cylindrical sleeve technology, applied in the field of automatic oil immersion mechanism of cylindrical sleeve hardware, can solve the problems of affecting the qualified rate, large manual labor, low efficiency, etc., and achieve uniform oil immersion, good effect and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

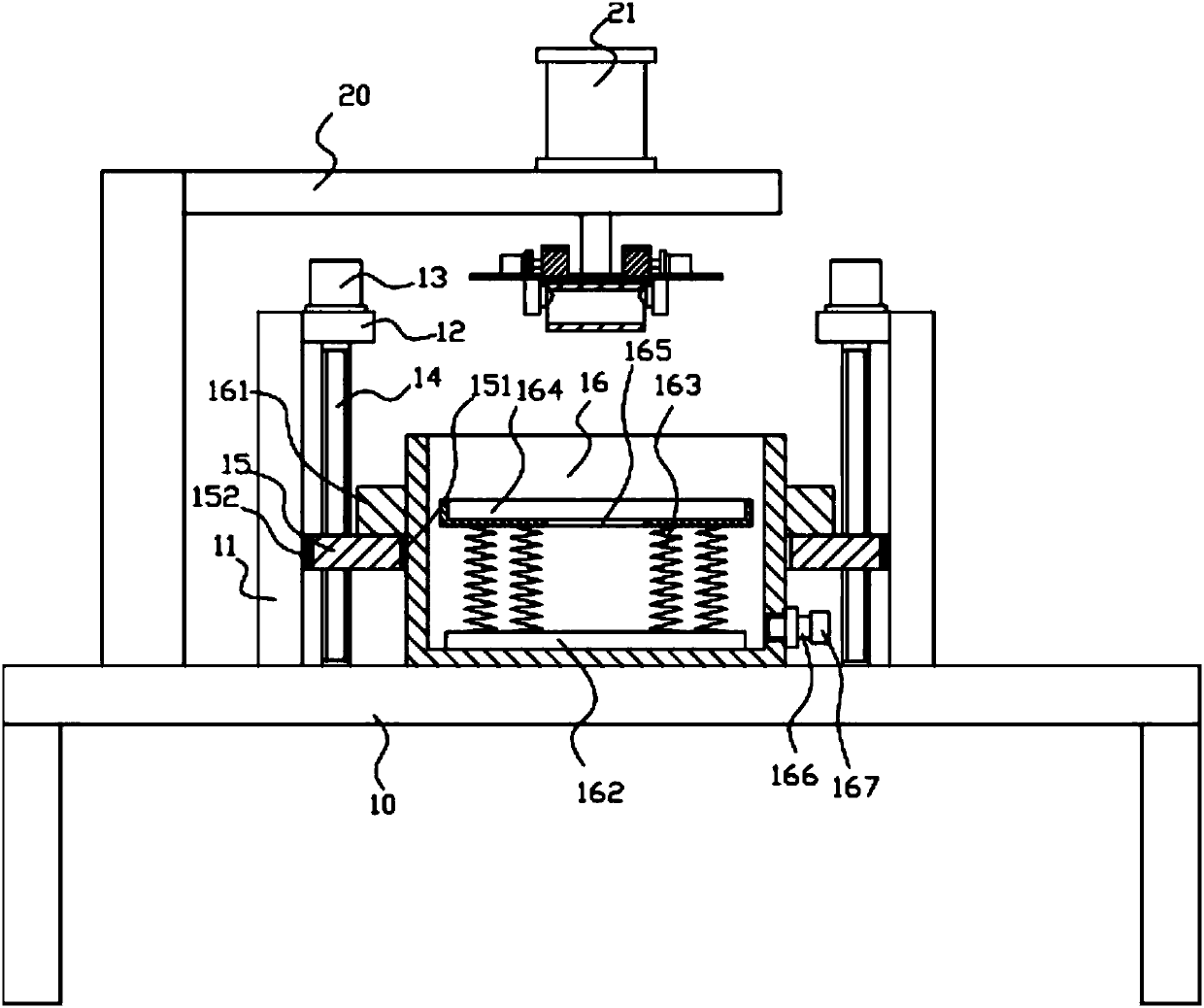

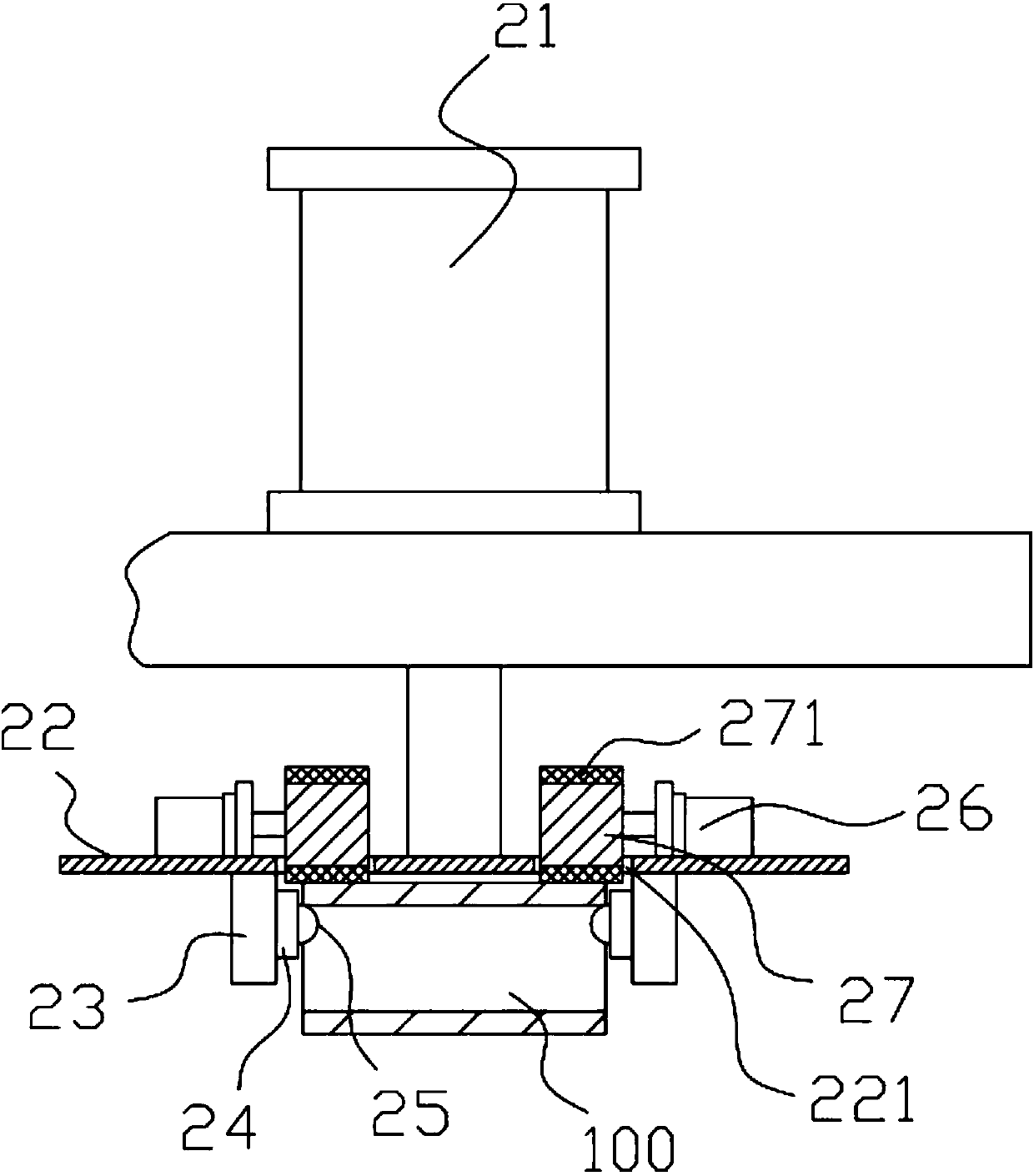

[0016] Example: see Figure 1 to Figure 2 As shown, an automatic oil immersion mechanism for cylindrical sleeve hardware includes a frame 10, an upper support frame 20 is fixed on the top surface of the top plate of the frame 10, and a main lifting frame is fixed on the top surface of the top plate of the upper support frame 20. Cylinder 21, the push rod of main lifting cylinder 21 passes through the top plate of upper support frame 20 and is fixed with grab lifting plate 22, grabs the bottom surface of both sides of lifting plate 22 and is fixed with vertical grab plate 23, two vertical grabs The side connection block 24 is fixed on the opposite wall surface of the plate 23, and the ball plunger 25 is screwed on the opposite wall surface of the two side connection blocks 24. The cylindrical sleeve 100 to be processed is between the two side connection blocks 24, and the The steel ball of the head plunger 25 extends into the cylindrical sleeve 100 to be processed and presses a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com