Oil immersion mechanism for mechanical production

An oil-immersed and mechanical technology, applied in the mechanical field, can solve problems such as uneven distribution of parts, affecting quality, and omissions, and achieve the effect of simple overall structure, strong practicability, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

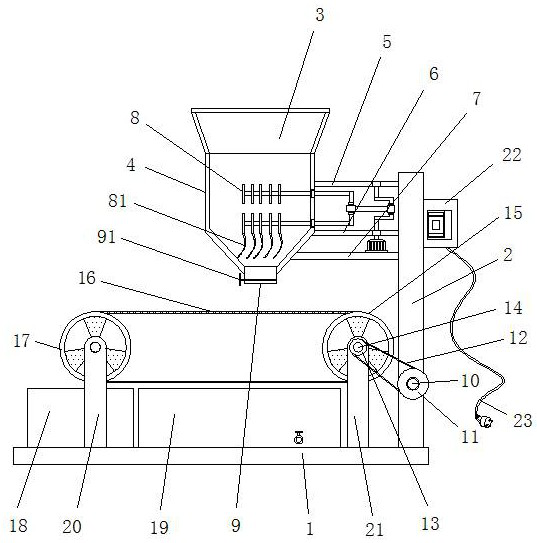

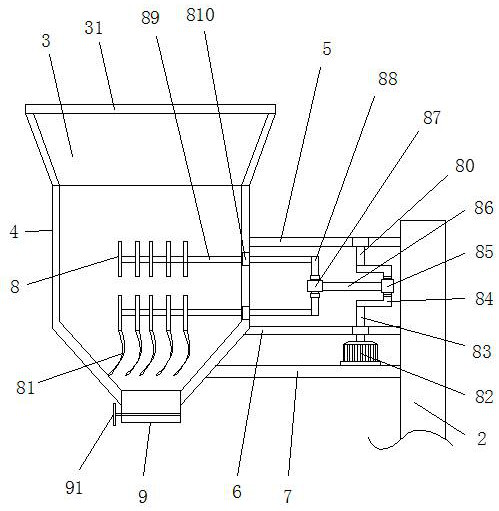

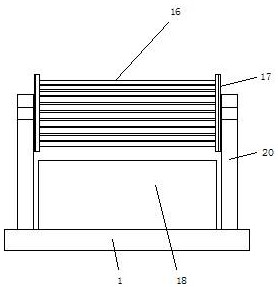

[0025]referenceFigure 1-5In this embodiment, a mechanical production is proposed, including a bottom plate 1, and the top right end of the bottom plate 1 is fixedly mounted having a fixing frame 2, and the left side of the fixing frame 2 is provided for immersion of zero. The oil's immersion can 4, and the soaking canister 4 and the holder 2 are sequentially connected by the first support frame 5, the second support frame 6, the third support frame 7, and the immersion can 4 The inner setting is a mixed mechanism for soaking the zero substance, and the top of the tank can 4 is provided with a feed port 3, and the bottom of the immersion can 4 is provided with a discharge opening 9, which is discharged. The lower part of the port 9 is provided with an oil filter belt 16. The right side of the bottom plate 1 is fixed to the right bracket 21, and the right bracket 21 is located on the left side of the fixing frame 2, and the right bracket 21 is rotated and installed with the first netw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com