Efficient flax thread oil immersion device for spinning

A high-efficiency, twine technology, applied in the textile field, can solve the problems of poor oil immersion effect and low efficiency, and achieve the effect of reducing labor intensity, preventing damage and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

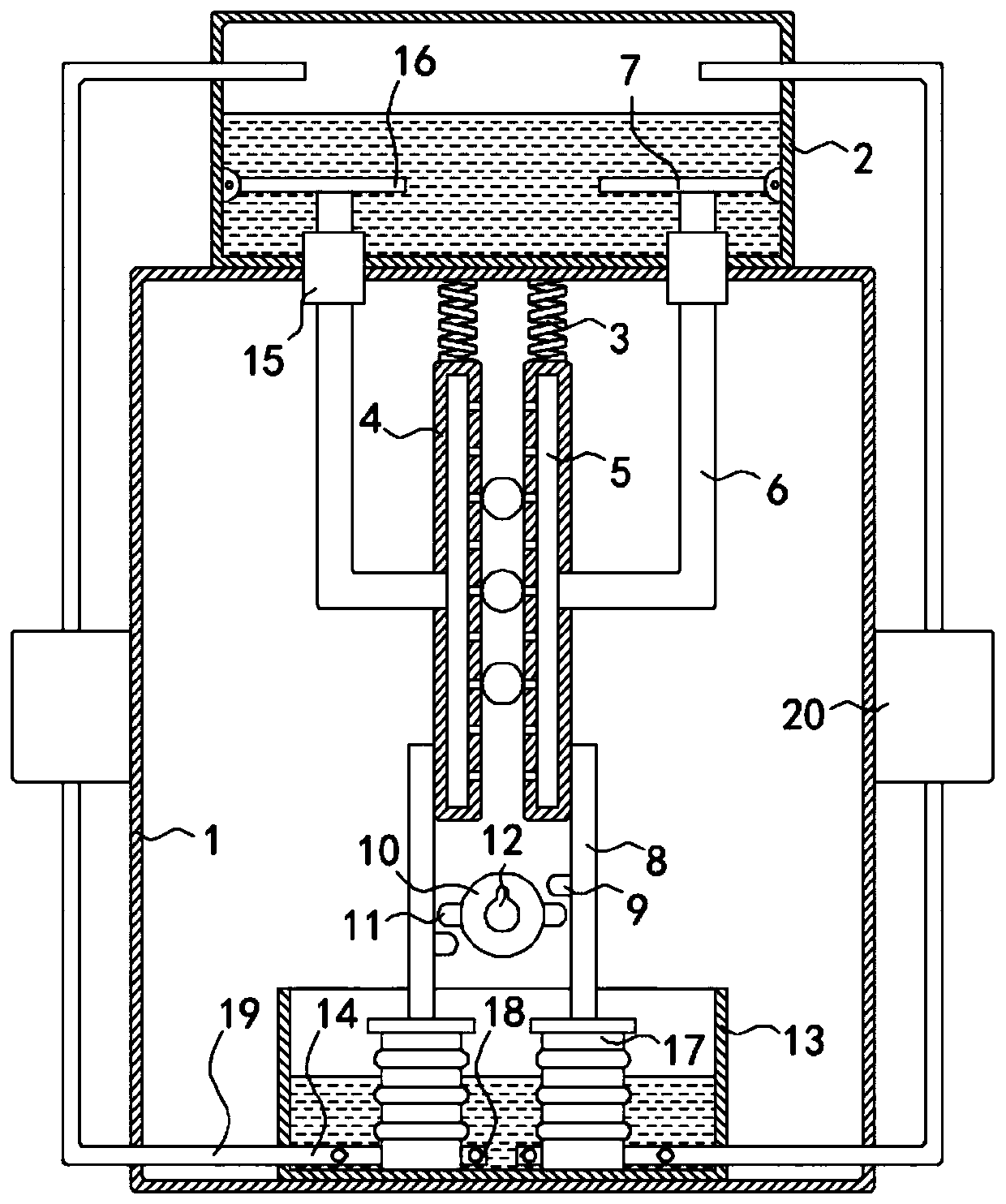

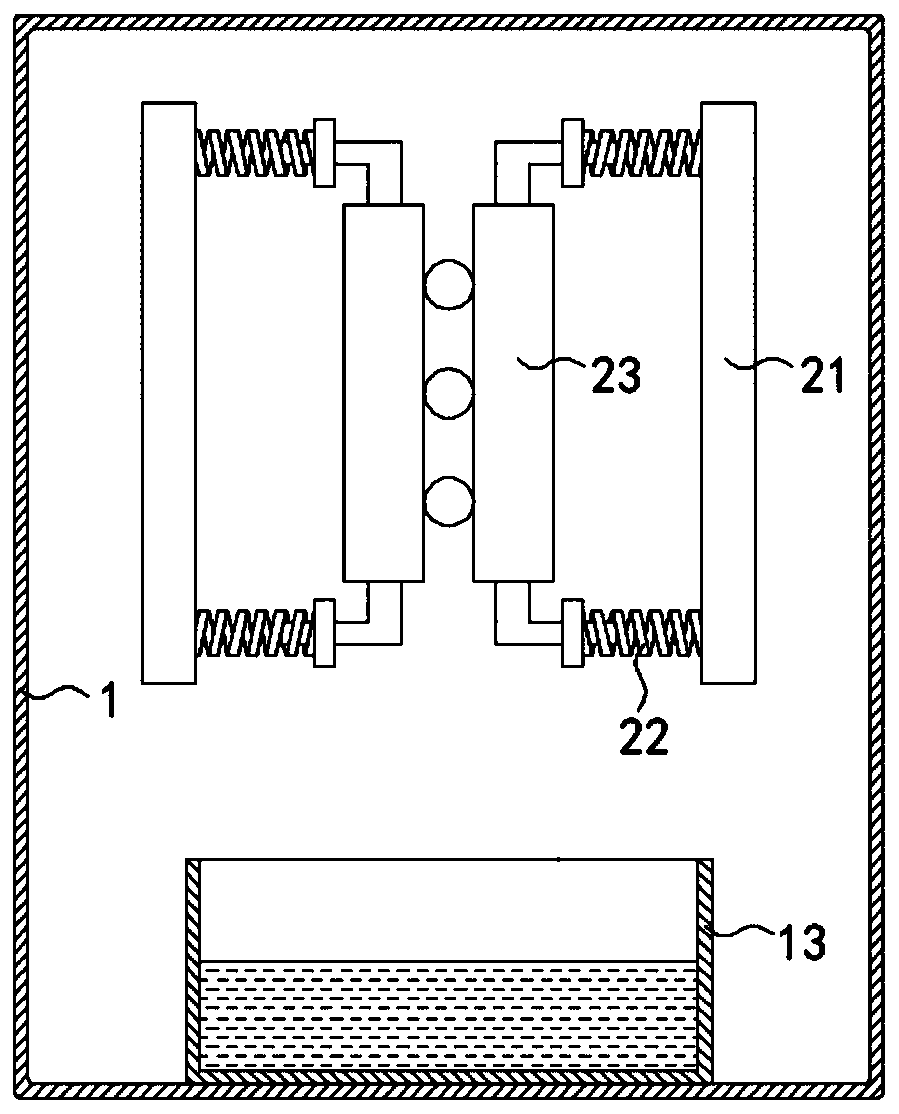

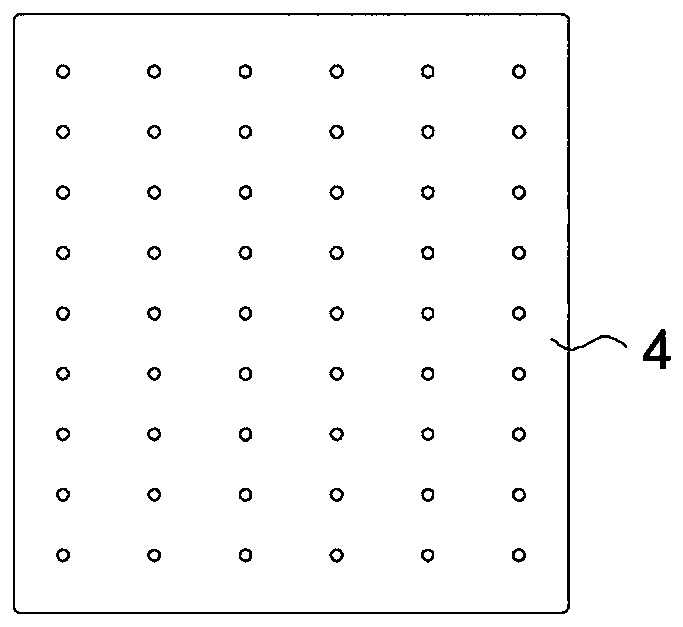

[0027] Such as Figure 1-4 As shown, a high-efficiency hemp thread oil immersion device for textiles includes a housing 1, and the side walls of the front and rear sides of the housing 1 are respectively provided with inlet holes and wire outlet holes, and the wire inlet holes and wire outlet holes are all arranged in a strip shape. It can accommodate multiple hemp threads to pass side by side. The upper end of the housing 1 is fixedly connected with the oil storage tank 2. The inner top surface of the housing 1 is fixedly connected with two rubbing boards 4 arranged side by side and vertically through two return springs 3. The interior of the kneading board 4 is provided with an oil storage chamber 5, and the side walls of the two kneading boards 4 that are close to each other are provided with a plurality of oil outlet holes that communicate with the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com