Welding device for kettle spout

A technology of welding device and spout, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve problems such as unstable welding operation, poor welding effect, and irregular weld shape, and achieve stable, efficient, and good welding Practical application and promotion value, the effect of simple and exquisite structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

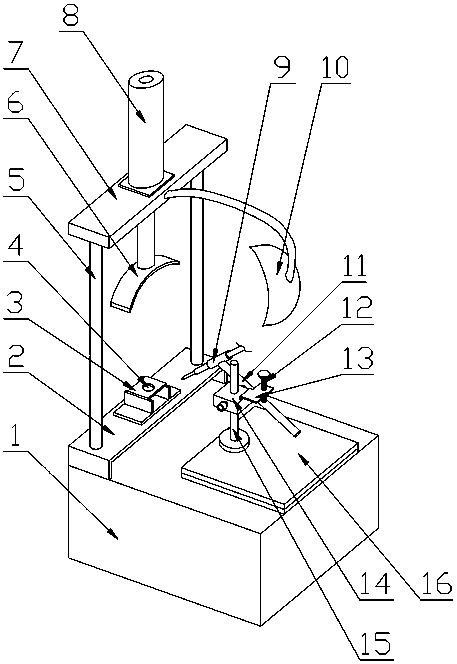

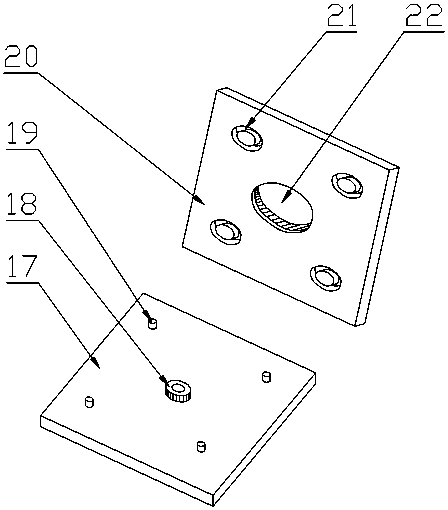

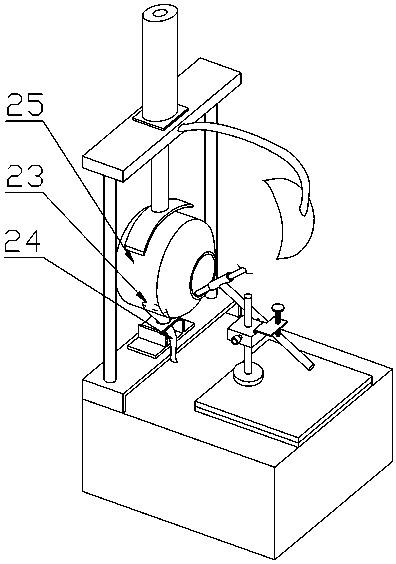

[0013] see figure 1 , figure 2 , the present invention is a kettle spout welding device, which has a base 1, a bracket plate 2 is arranged on one side of the base, a spout shelf 3 is framed in the middle of the bracket plate, a spout hole 4 is arranged on the spout shelf, and the bracket There are struts 5 on both sides of the plate, a cylinder plate 7 is erected on the upper part of the strut, a press cylinder 8 is arranged vertically downward on the cylinder plate, and an arc-shaped pressing sheet 6 is arranged at the lower end of the piston rod of the press cylinder. The arc-shaped pressing piece is arranged opposite to the spout hole; the base on the other side opposite to the spout shelf is provided with a spout welding seam profiling plate 16, and the spout welding seam profiling plate There is a column 15 on the upper surface, the column is aligned with the spout hole, the column is provided with a mounting seat 14 that can be adjusted up and down along the column, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com