Cutting machine with automatic feeding function, and use method of cutting machine

An automatic feeding and cutting machine technology, applied in special forming/shaping machines, manufacturing tools, wood processing appliances, etc., can solve problems such as low work efficiency of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

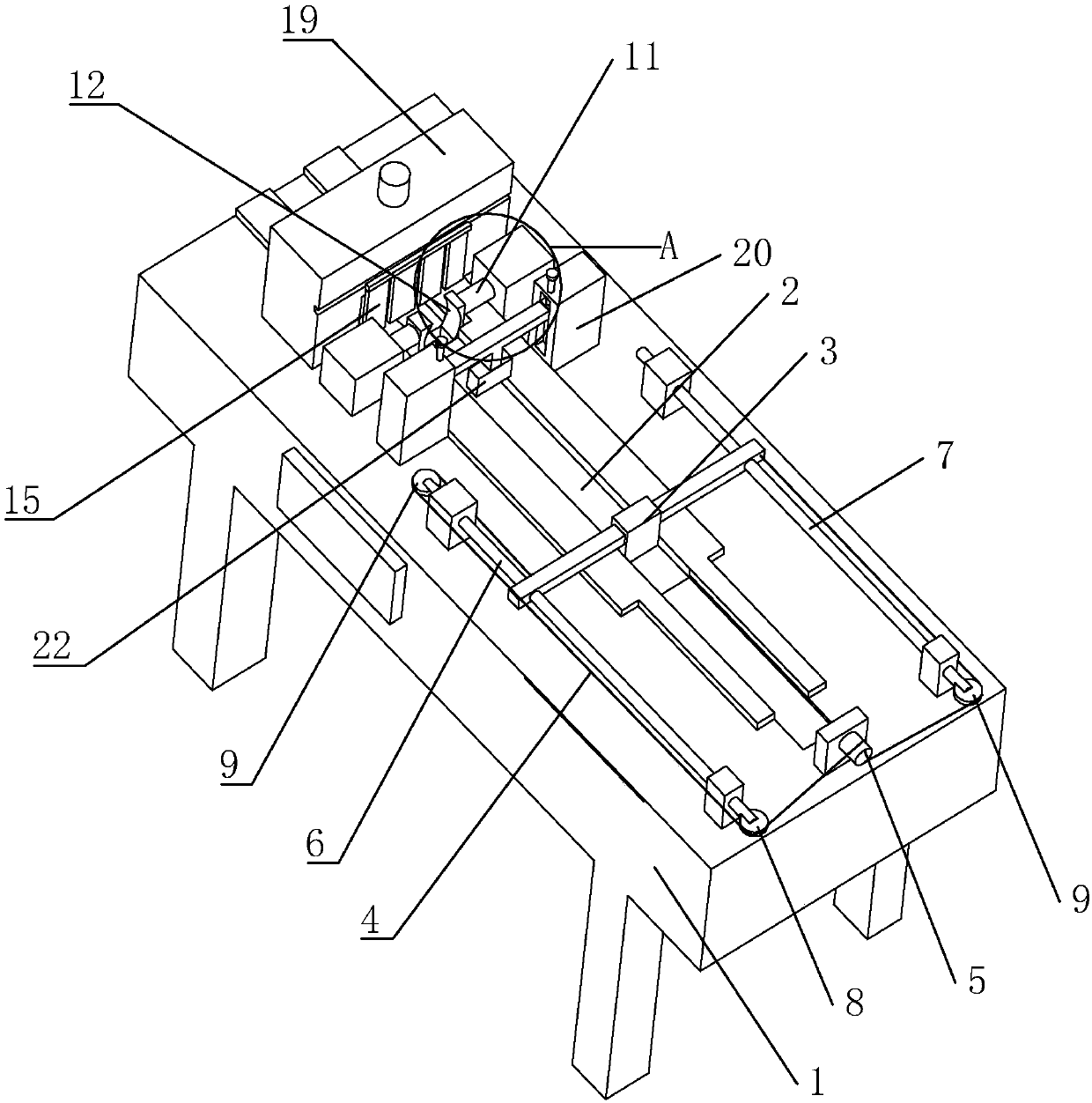

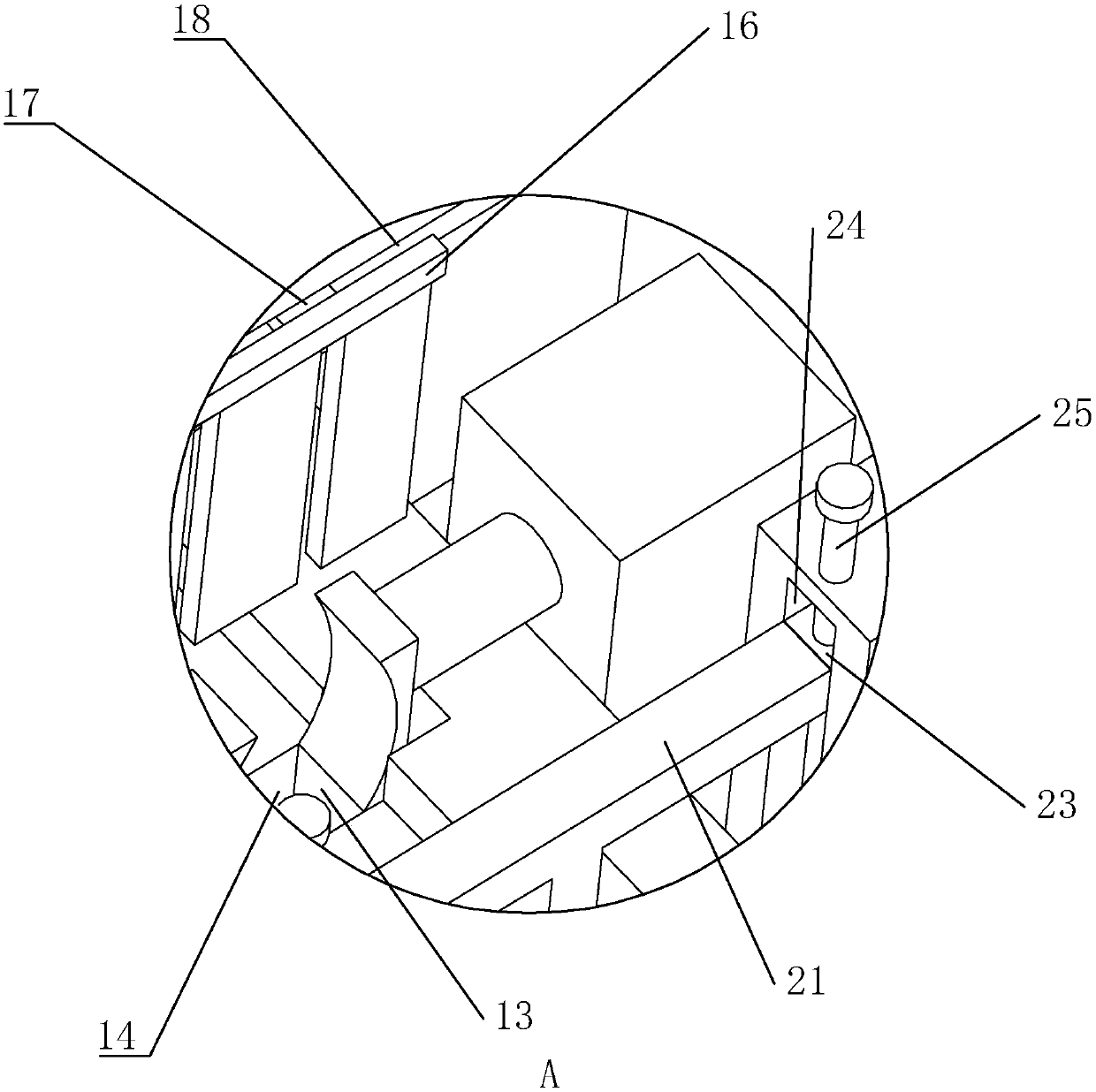

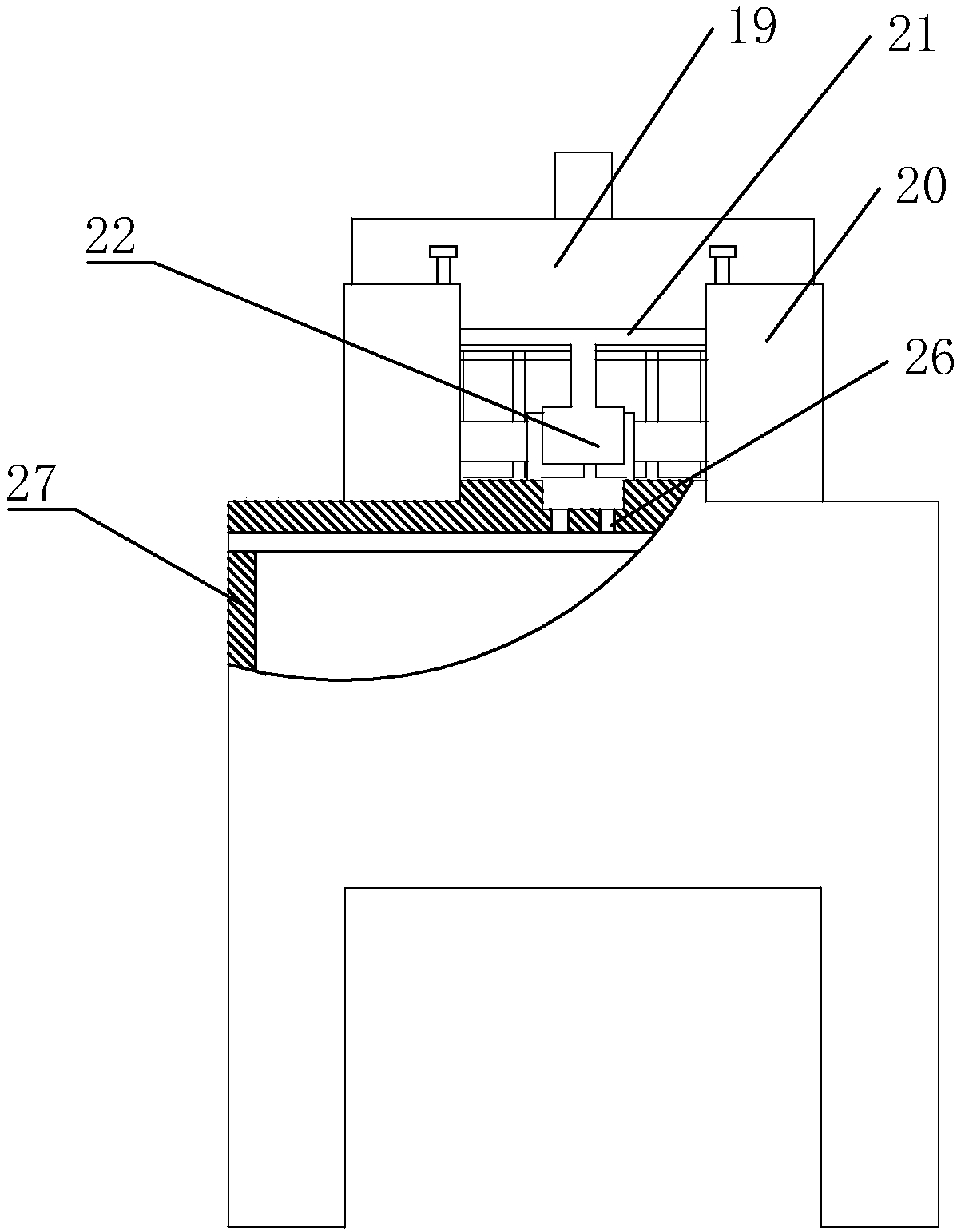

[0022] refer to Figure 1 to Figure 3 As shown, a cutting machine with automatic feeding function implemented in this case includes a body 1, the body 1 is provided with a material guide trough 2 and a support frame 19, and the material guide trough 2 includes a discharge end and a feeder end, the support frame 19 is provided with a tool corresponding to the guide groove 2, and a push cylinder is provided between the tool and the support frame 19, and one end of the push cylinder is connected with the support frame 19, and the other end is connected with the tool , the support frame 19 is provided with a feed end and a discharge end, and the body 1 is provided with a mounting frame 20 near the feed end, and the mounting frame 20 is provided with an adjusting rod 21, and the adjusting rod 21 is supported in the guide Above the material trough 2, the adjusting rod 21 is provided with a hairbrush 22, the two ends of the adjusting rod 21 are provided with a movable block 23, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com