Cutting machine for automatic loading of furniture plates and using method of cutting machine

An automatic feeding and cutting machine technology, which is applied in the direction of sawing components, manufacturing tools, sawing equipment, etc., can solve the problem of low work efficiency of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

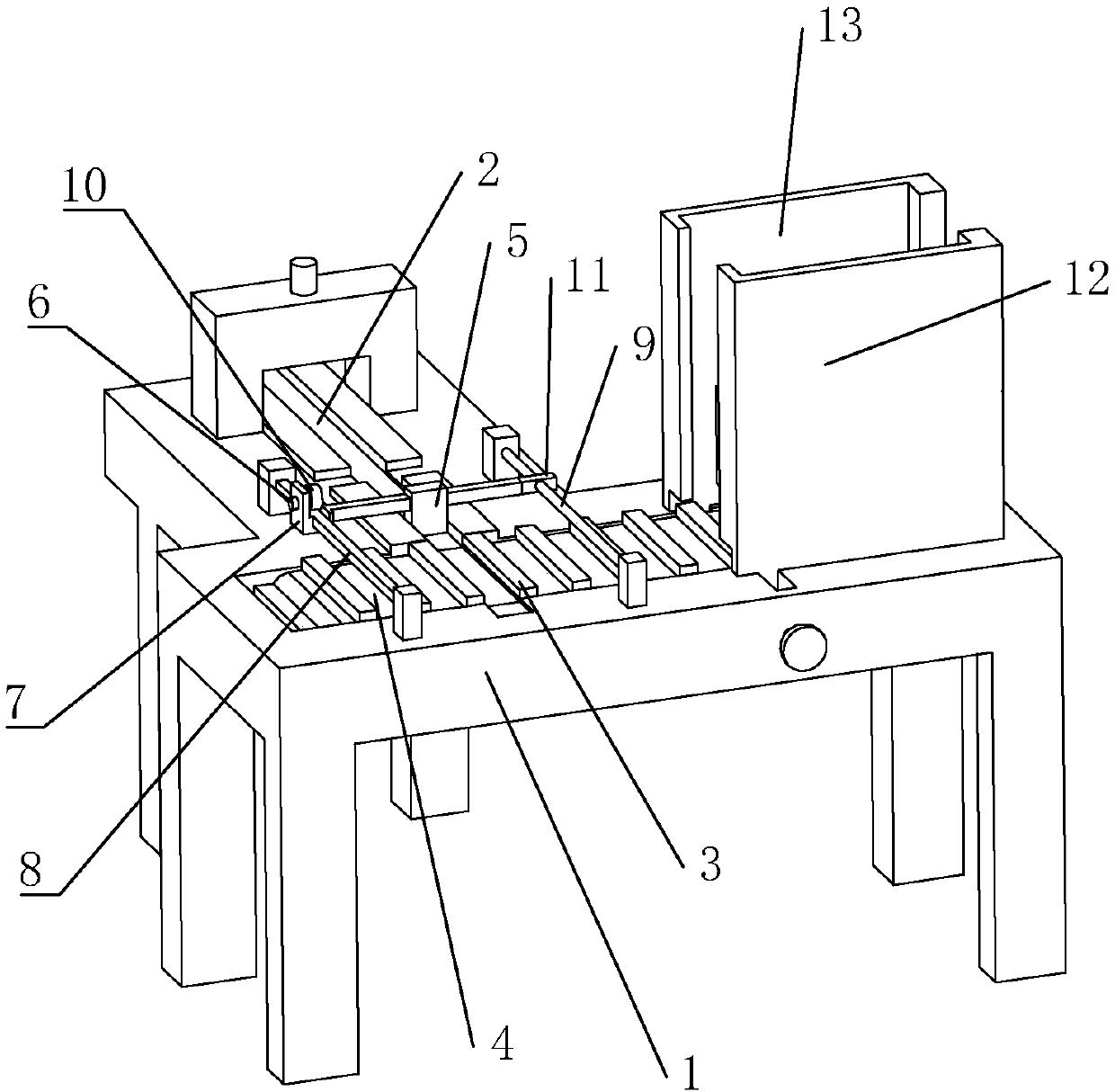

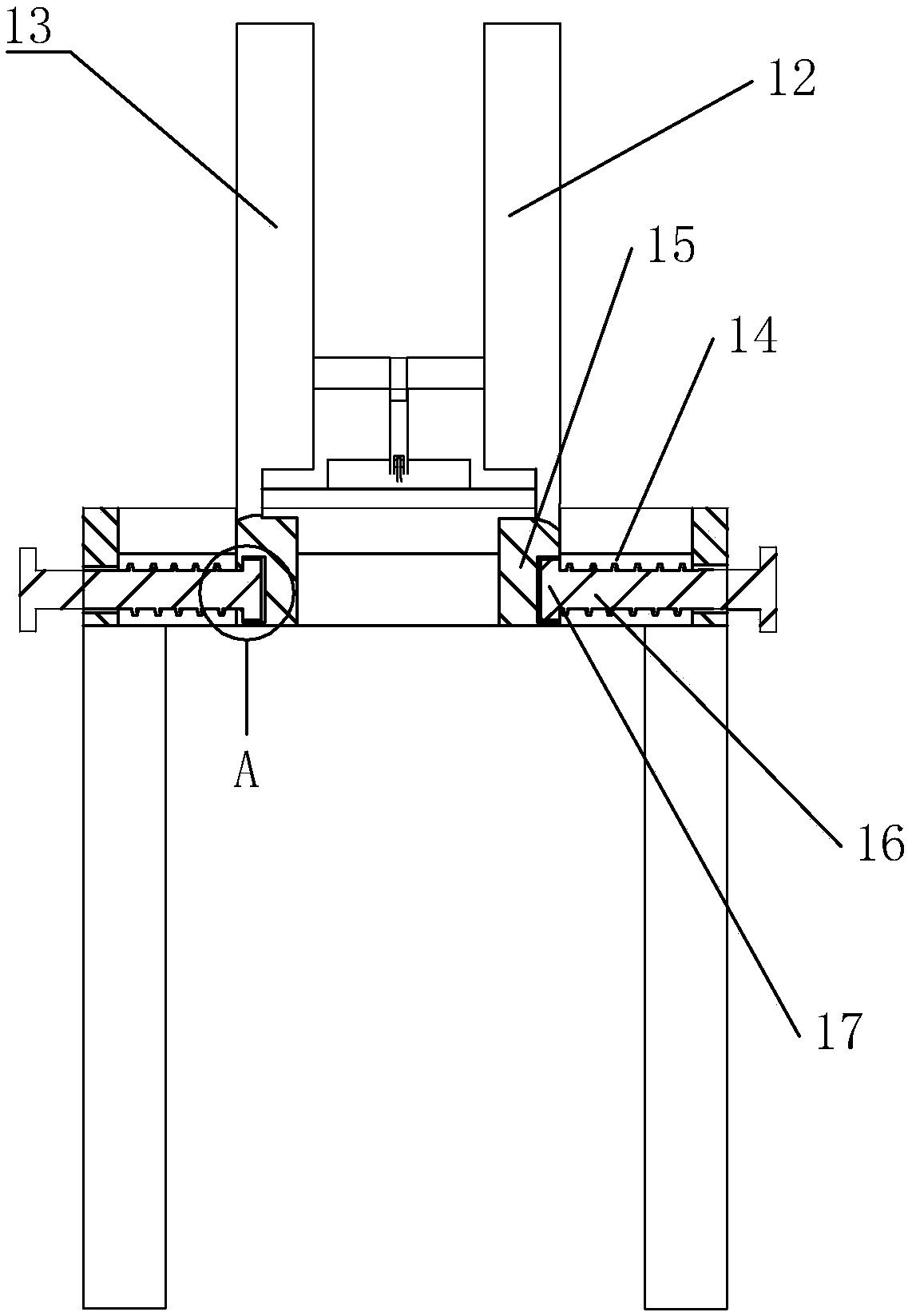

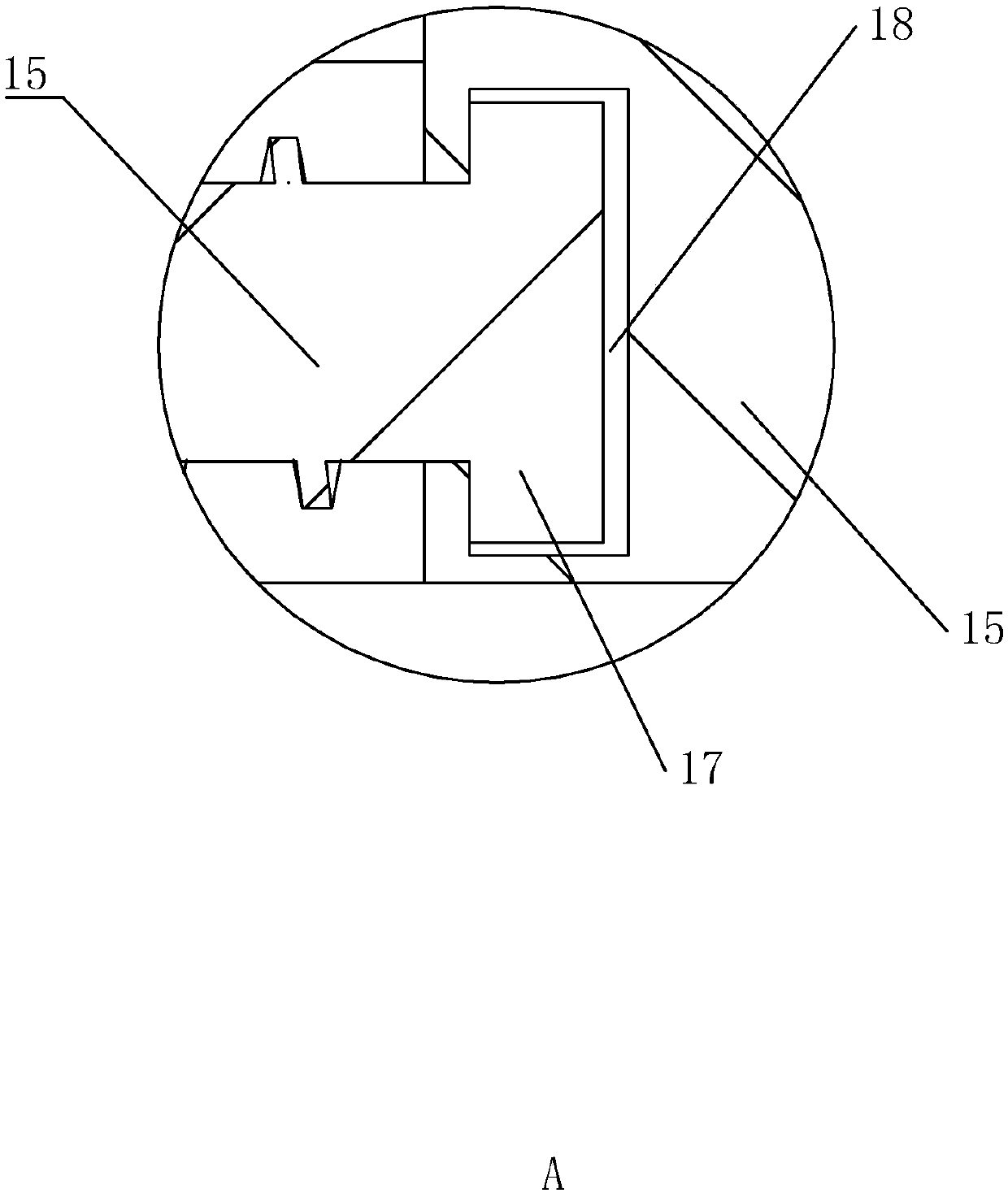

[0020] refer to Figure 1 to Figure 3 As shown, a cutting machine for automatic loading of furniture panels implemented in this case includes a body 1, and the body 1 is provided with a material guide trough 2, and the material guide trough 2 includes a discharge end and a feed end. The body 1 is also provided with a material box, and a conveyor belt 3 is provided between the material box and the body 1. The conveyor belt 3 is provided with some discharge troughs 4 corresponding to the feed end, and the material box is provided with There is a discharge port corresponding to the discharge trough 4, the width of the discharge port matches the diameter of the wood, the material box includes a first box body 12 and a second box body 13, and the body 1 is provided with a first A chute 14 that slides between a box body 12 and the second box body 13, the first box body 12 and the second box body 13 are provided with a slide block 15 that cooperates with the chute 14, and the body 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com