Cutting machine and method for applying same

A cutting machine and machine body technology, applied in the direction of sawing components, sawing equipment, circular saws, etc., can solve the problem of low work efficiency of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

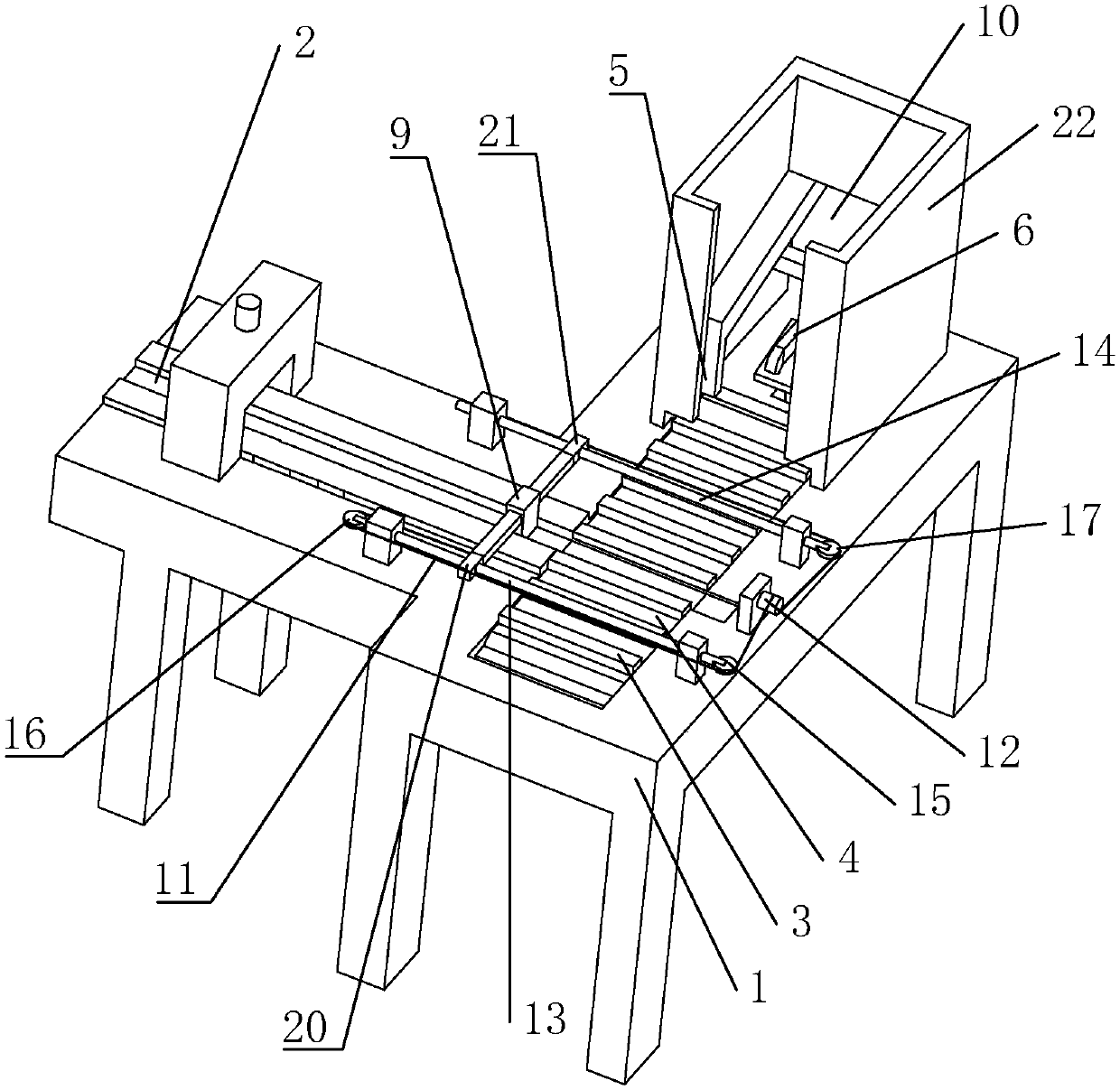

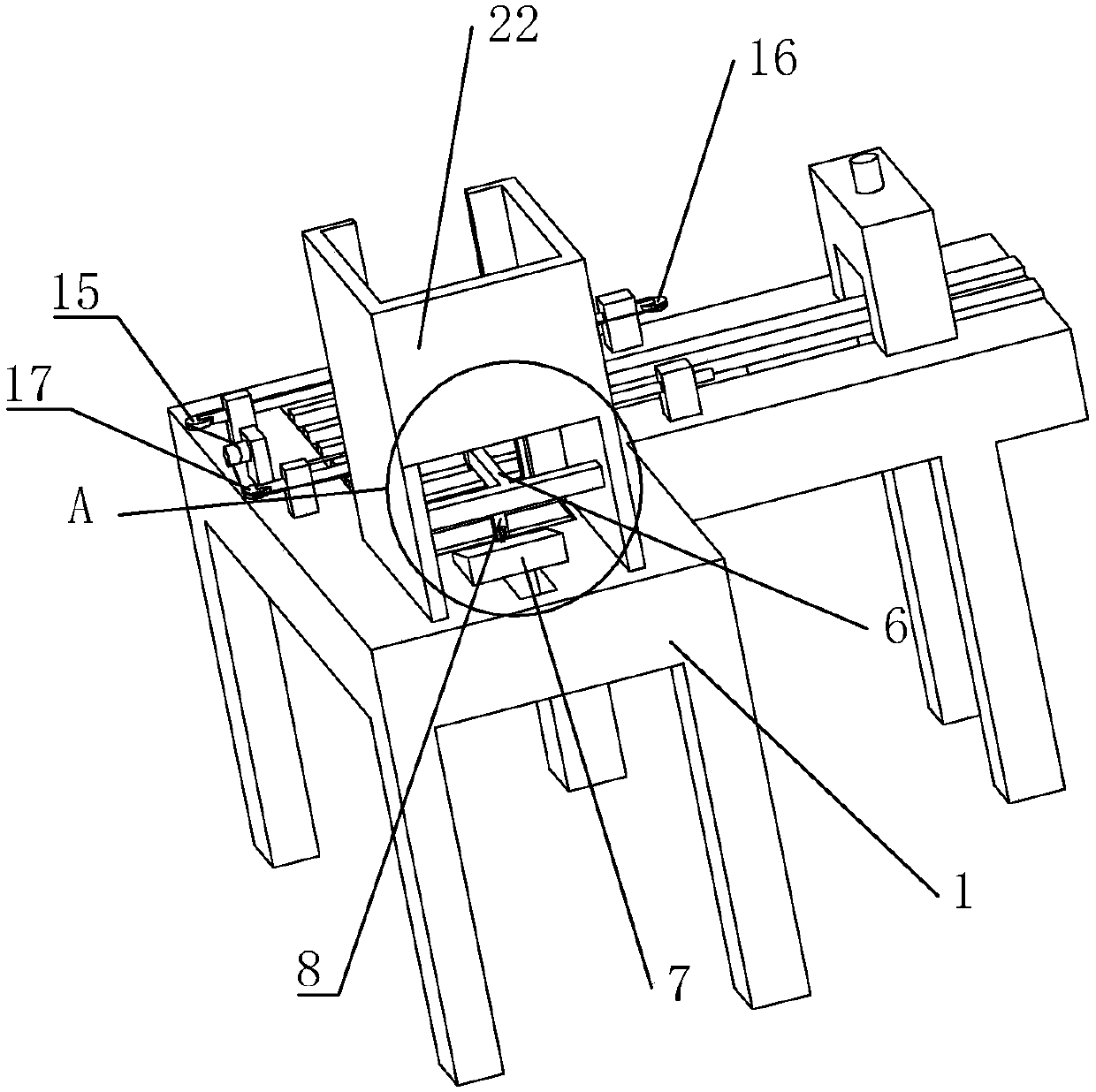

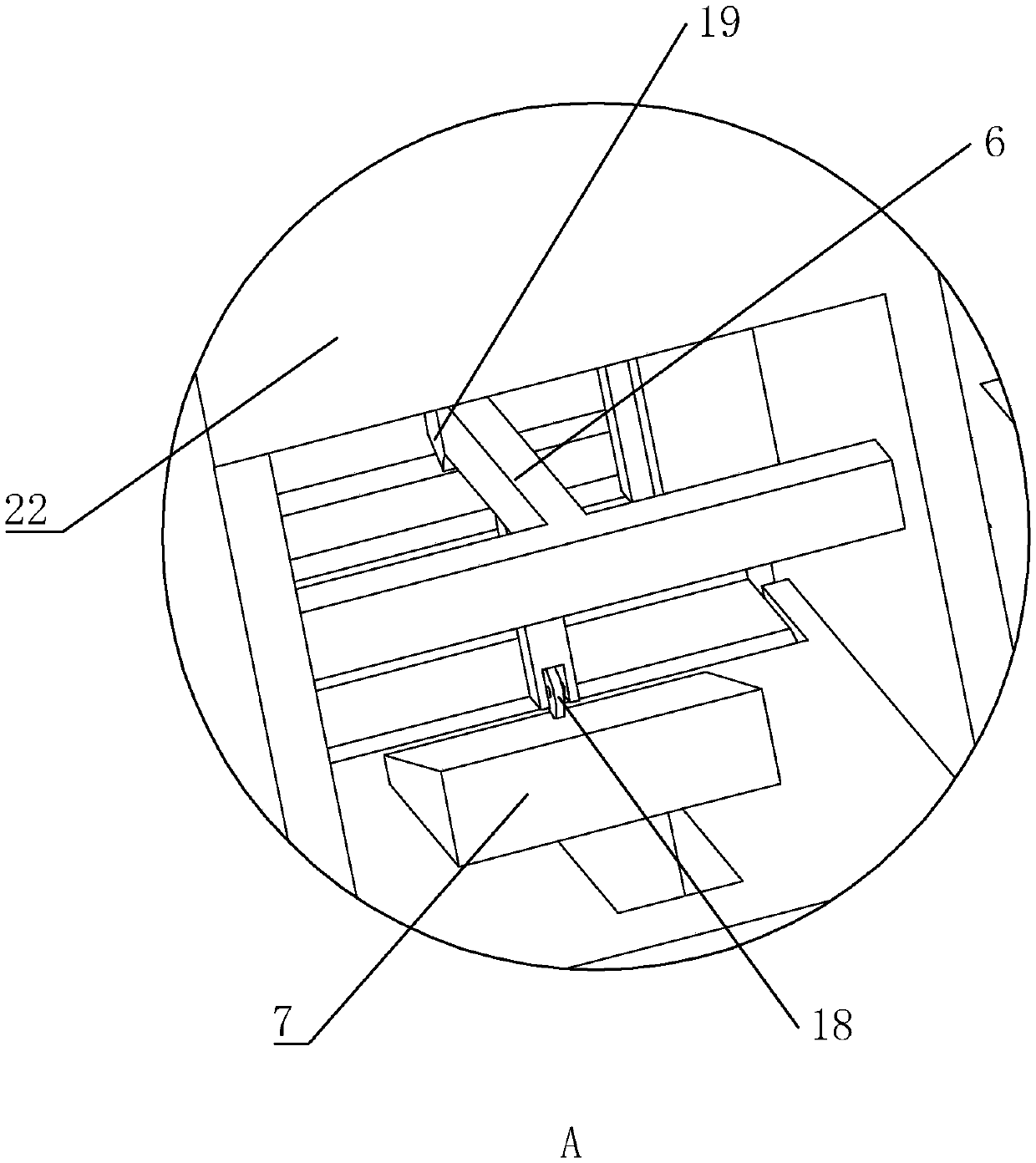

[0020] refer to Figure 1 to Figure 3 As shown, a cutting machine implemented in this case includes a body 1, the body 1 is provided with a material guide trough 2, the material guide trough 2 includes a discharge end and a feed end, and the body 1 is also provided with a material Box 22, a conveyor belt 3 is provided between the hopper 22 and the body 1, and a number of discharge troughs 4 corresponding to the feed end are provided on the conveyor belt 3, and a discharge chute 4 corresponding to the feed end is provided on the hopper 22. The discharge port 5 corresponding to the trough 4, the width of the discharge port 5 matches the diameter of the wood, and an adjusting device for regulating the entry of the wood into the discharge port 5 is provided between the body 1 and the feed box 22. The adjustment device includes an adjustment rod 6 and an adjustment plate 7, a support rod 8 is provided between the adjustment rod 6 and the adjustment plate 7, the adjustment rod 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com