Plastic extruder

A plastic extruder and extrusion die technology, applied in the field of plastic extruder equipment, can solve the problems of plastic decomposition, easily destroying molecular chains, affecting the quality of extruded plastics, etc., and achieves good plasticizing effect and high extrusion efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

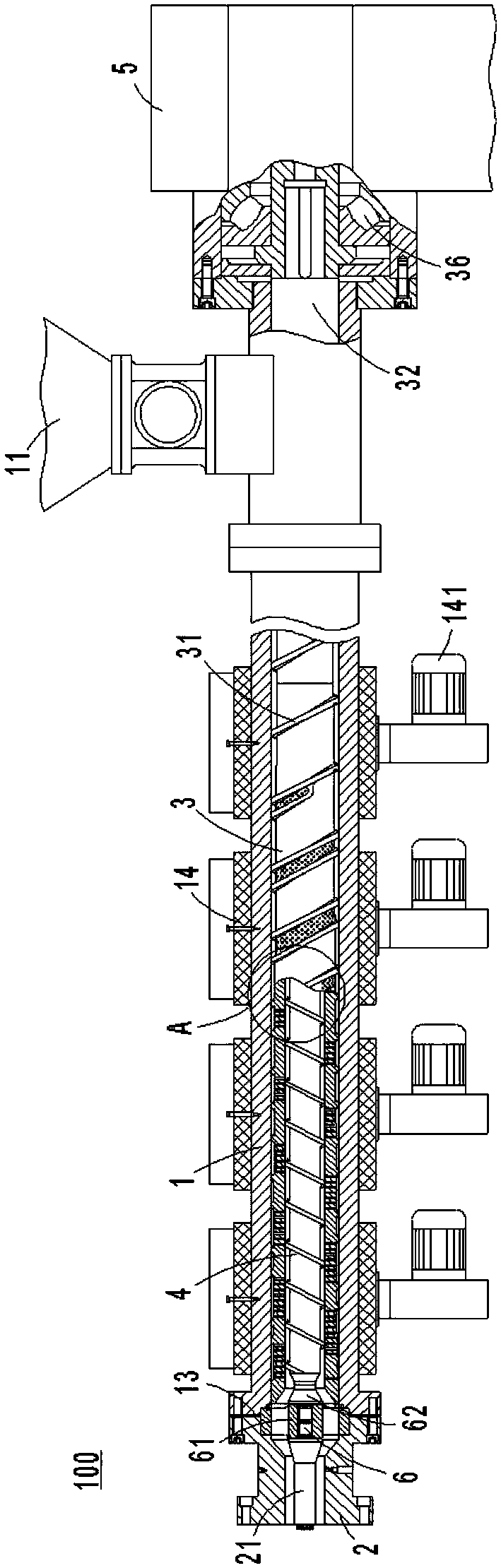

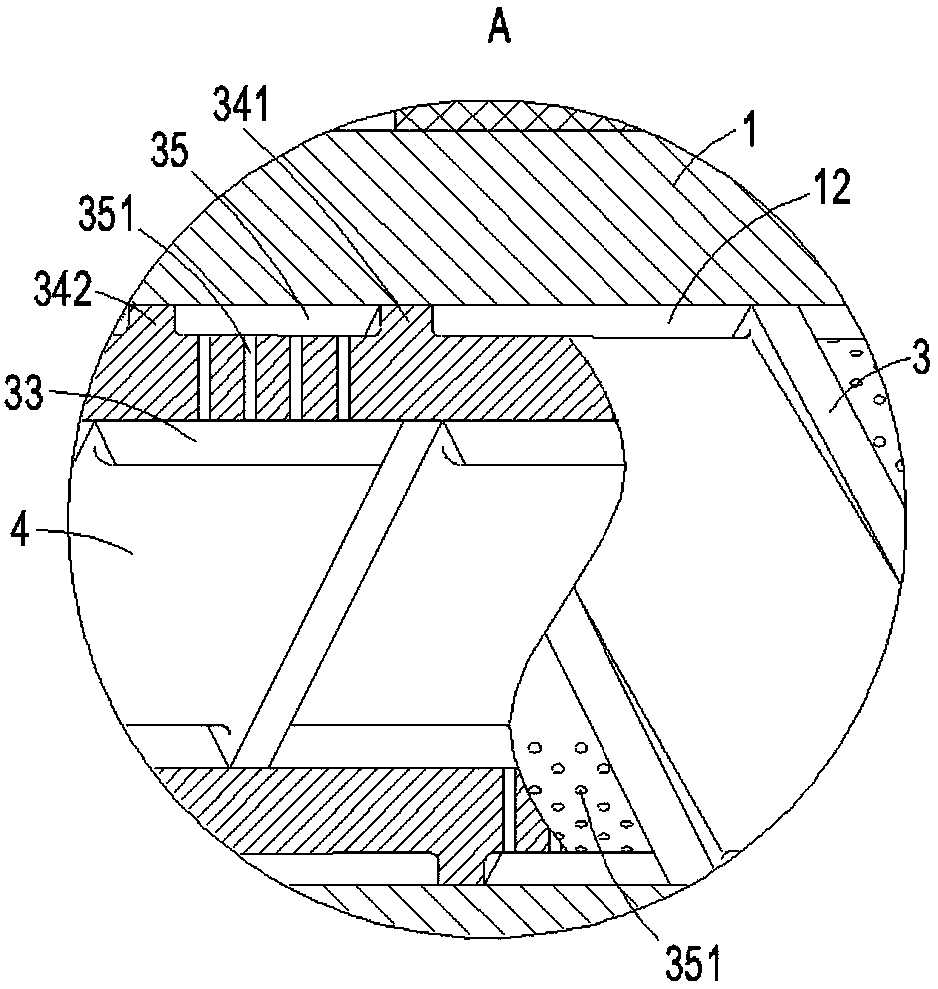

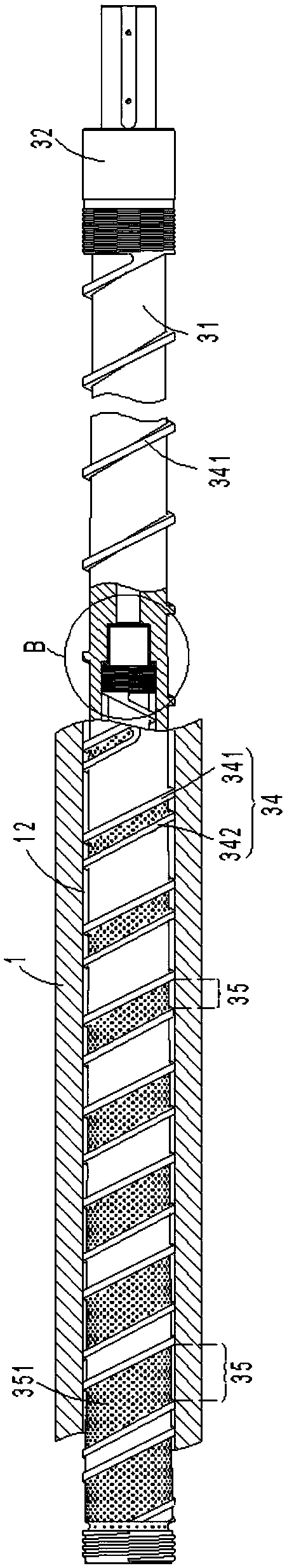

[0029] In order to describe the technical content, structural features, achieved goals and effects of the invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings. Among them, the "front" and "rear" mentioned in this embodiment are respectively attached figure 1 The left and right directions shown in the figure 1 The direction extending left and right along the outer screw / inner screw / extruder barrel shown in , "circumferential" is attached figure 1 The direction around the outer circumference of the outer screw / inner screw / extrusion barrel shown in , "radial" refers to the attached figure 1 The directions extending along the radius of the cross-sectional circle of the outer screw / inner screw / extruder barrel shown in .

[0030] as attached figure 1 The shown plastic extruder 100 comprises a long cylindrical extruder barrel 1, the inside of the extruder barrel 1 is a hollow structure and forms a heating chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com