Improved paint barrel

A technology for paint buckets and bucket bodies, which is used in coverings/exterior paints, parts of bottles/cans, caps with auxiliary devices, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

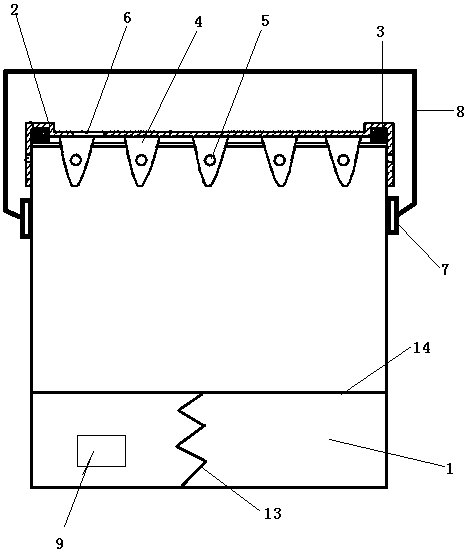

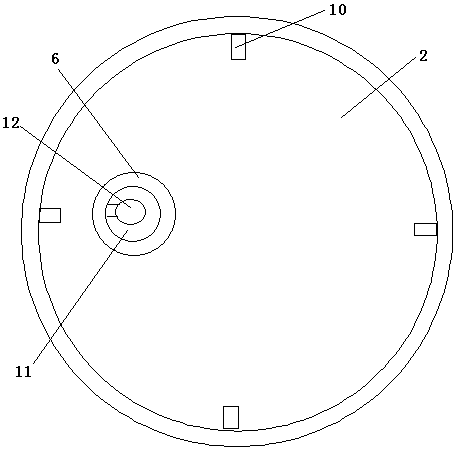

[0013] Example: such as figure 1 and figure 2 As shown, an improved paint bucket includes a cylindrical barrel body 1 and a circular barrel cover 2, the barrel cover 2 is provided with a circular discharge port 6, and a telescopic hose can be connected to the discharge port 6, which can facilitate When the paint is poured without opening the barrel cover 2, the telescopic hose is sealed by the sealing cover 11, and the sealing cover 11 is connected with the mouth of the telescopic hose through glue, which has a good sealing effect. The sealing cover 11 is provided with a pull ring 12 , the pull ring 12 is convenient for the paint user to pull the sealing cover 11 from the telescopic hose. Several reinforcing ribs 10 are evenly distributed on the front of the barrel cover 2, which plays a certain role in stability. The connected sealing ring 3 can effectively prevent the paint from volatilizing from the gap between the barrel cover 2 and the barrel body 1. The barrel cover 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com