Material box frame of industrial transportation vehicle

A technology for industrial transport vehicles and material boxes, applied in the field of material box racks, can solve problems such as inability to slow down material vibration, material box damage, and material stacking pressure, and achieve good ventilation effects, pressure reduction, and good cushioning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

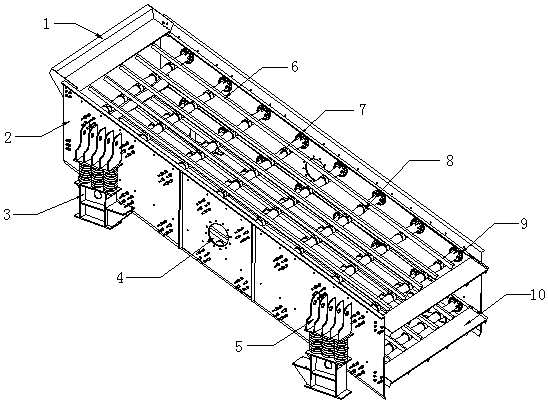

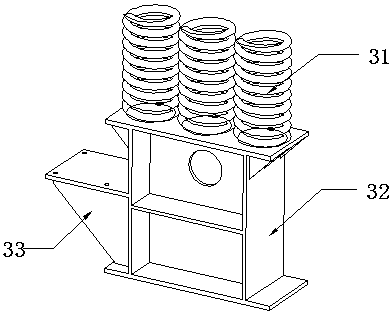

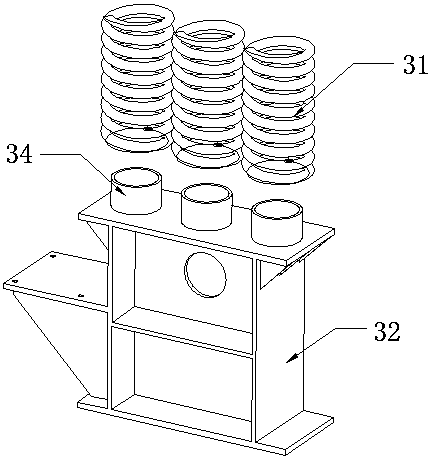

[0017] see Figure 1-3 As shown, a material box frame of an industrial transport vehicle includes a frame 2, a front plate 1 and a rear plate 10 are respectively installed at both ends of the top end of the frame 2, and two fixing plates 5 are provided on the side walls of the frame 2, and each The bottom of the fixed plate 5 is equipped with a shock absorber 3, the inside of the frame 2 is provided with several evenly distributed beams 6, the side wall of the frame 2 is provided with ventilation holes 4, and the inside of the frame 2 is provided with several support rods 7 , the surface of each support rod 7 is provided with several snap rings 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com