Blind corrugation end gland structure of container

A container and blind wave technology, which is applied in the field of containers, can solve the problem that the container blind wave end head structure does not have wire slots, etc., and achieve the effect of reducing the problem of wiring, reducing the overall quality, and improving the overall quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

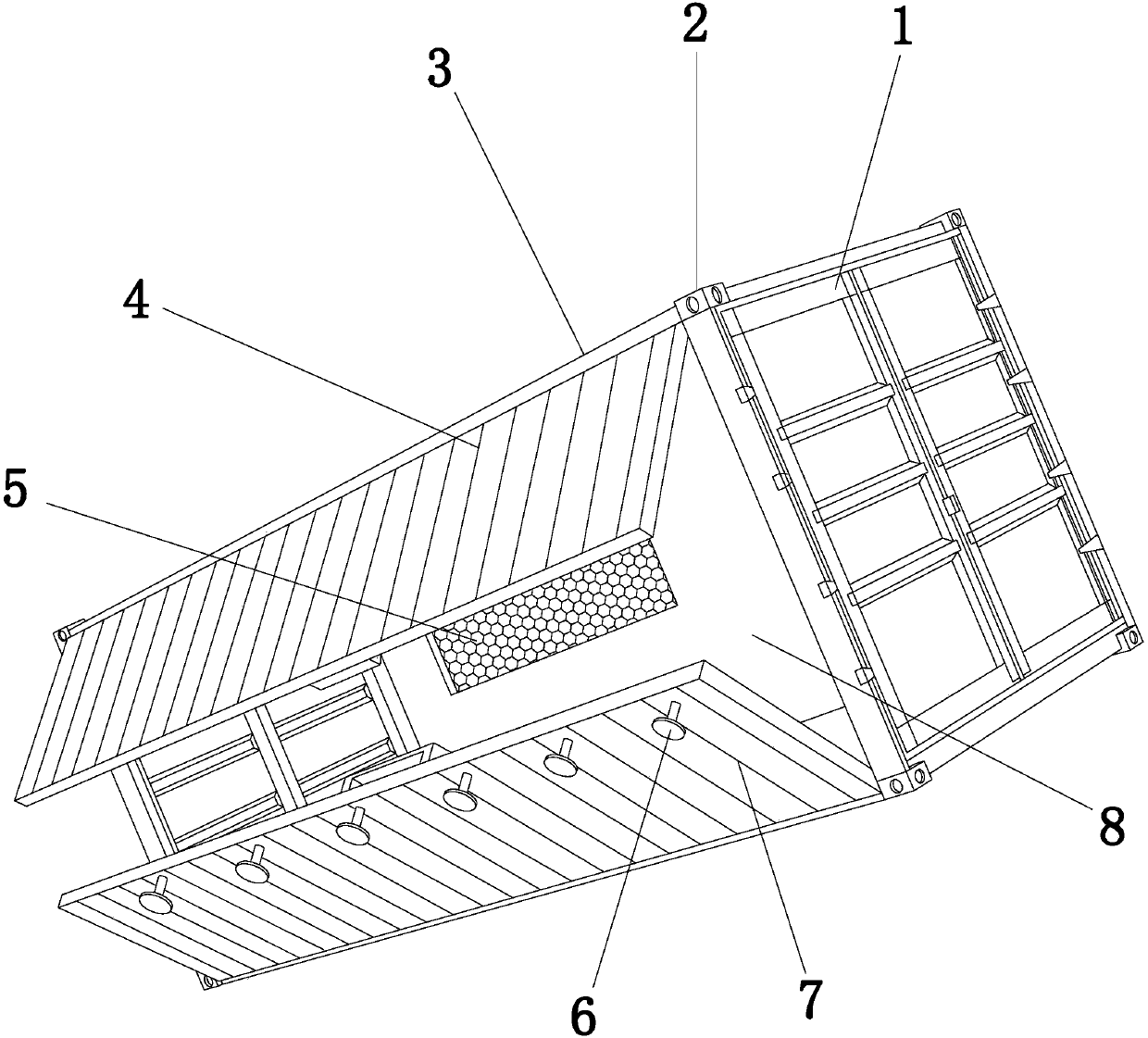

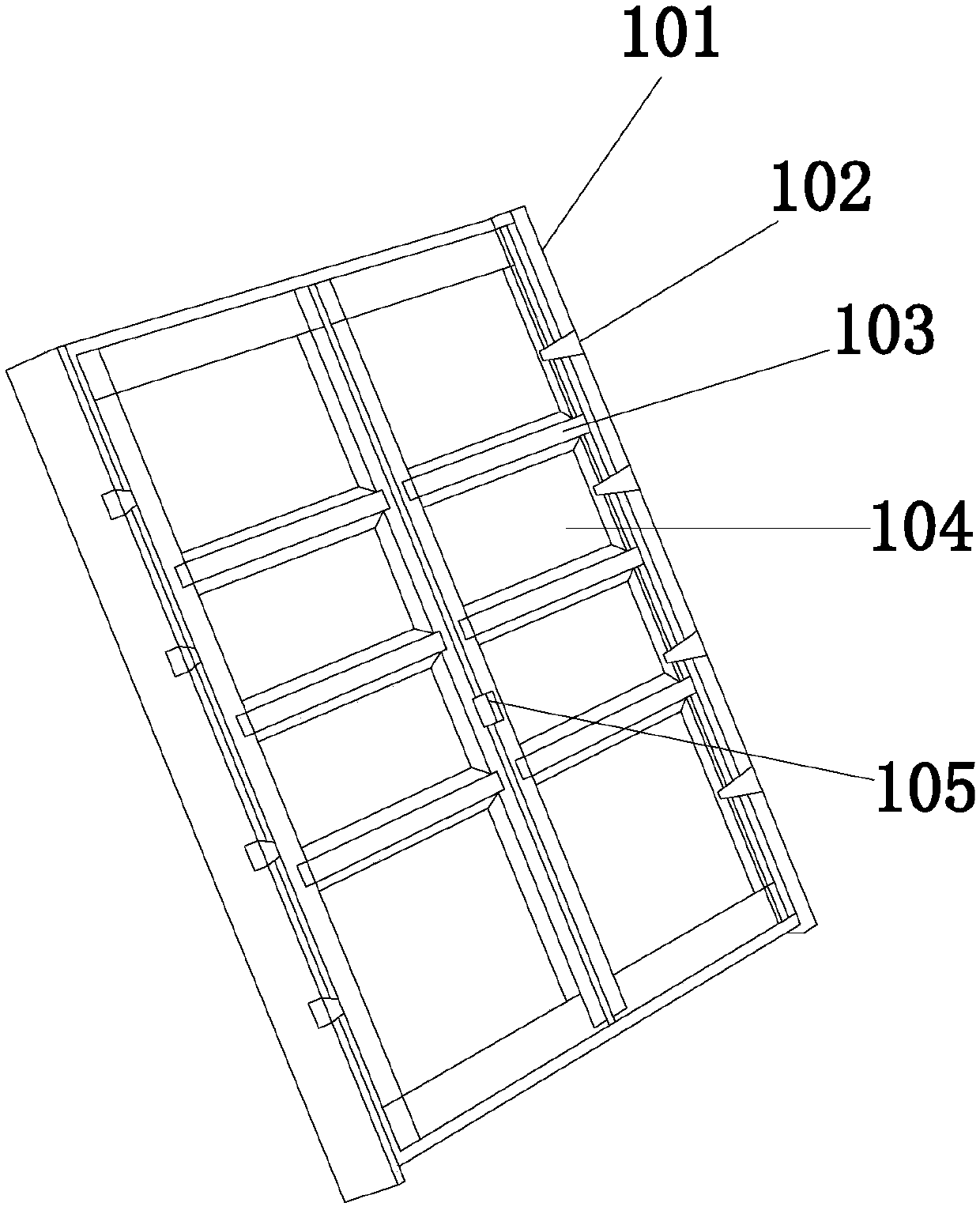

[0031] see Figure 1-Figure 7 , the present invention provides a container blind wave end head structure, which structure includes assembly door 1, blind wave end head 2, box body 3, No. 1 side sealing cover 4, sliding window 5, shock-absorbing auxiliary support feet 6 , No. 2 side seal cover 7, side wall panel 8;

[0032]The box body 3 has a rectangular structure and an assembly door 1 is provided at the front and rear ends, and the assembly door 1 is fastened and fixed on the box body 3, and the left side of the box body 3 is provided with a No. 1 side surface from top to bottom. Sealing cover 4 and No. 2 side sealing cover 7, described No. 1 side sealing cover 4 and No. 2 side sealing cover 7 are hingedly connected with casing 3, described No. 1 side sealing cover 4 and No. 2 side sealing cover 7 Matching, the outer wall of the No. 2 side sealing cover 7 is equidistantly provided with six shock-absorbing auxiliary supporting feet 6, and the described auxiliary shock-absorb...

Embodiment 2

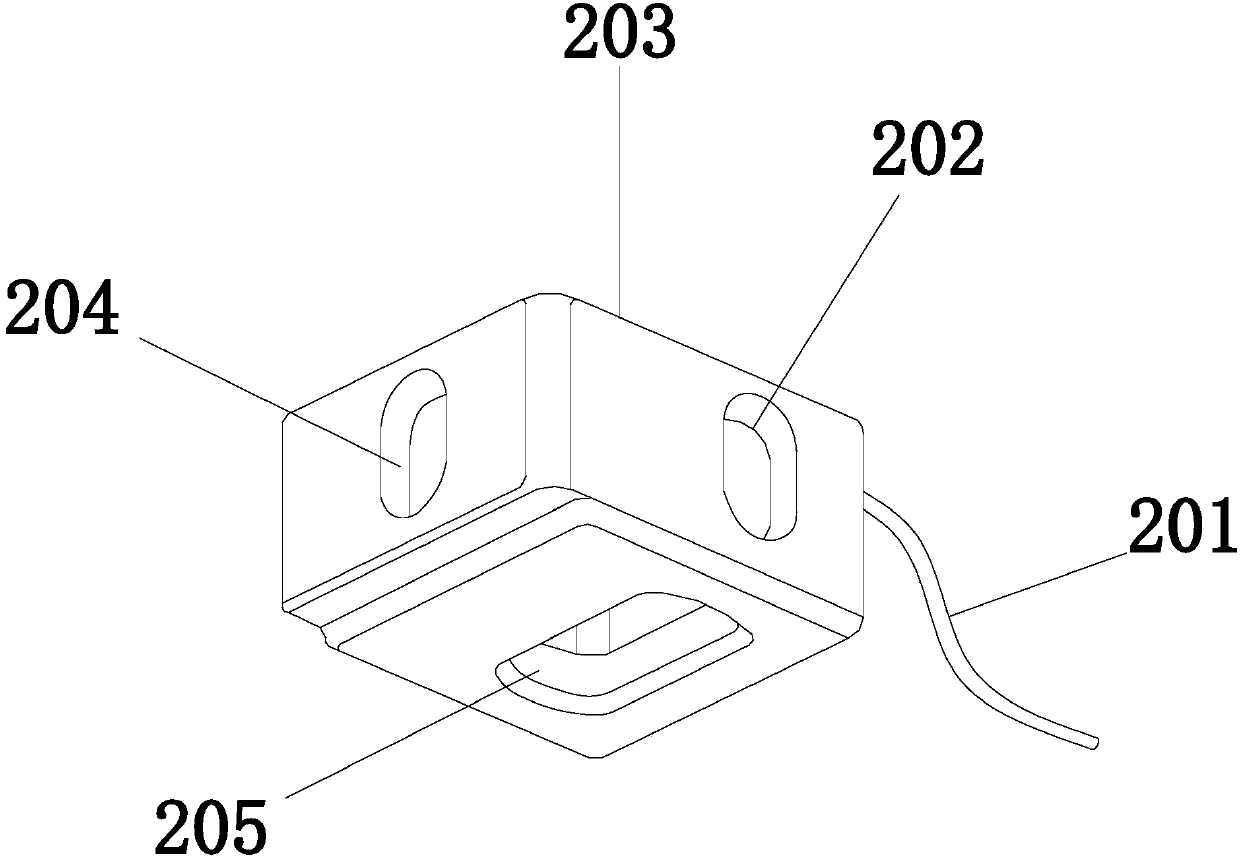

[0036] see Figure 1-Figure 8 The shock-absorbing auxiliary support foot 6 of the present invention is composed of bolts 601, hexagonal lock nuts 602, gaskets 603, load-bearing plate 604, and rubber body 605. The load-bearing plate 604 is a circular structure and the center position of the top is set There are bolts 601, and the bolts 601 are vertically fixed on the load-bearing plate 604, and three hexagonal lock nuts 602 are equidistantly arranged on the said bolts 601, and the said hexagonal locknuts 602 and the bolts 601 adopt clearance fit, so The washer 603 is fastened on the bolt 601 and matched with the hex lock nut 602 , and the rubber body 605 is tightly fixed on the bottom of the bearing plate 604 .

[0037] How the shock-absorbing auxiliary support foot works:

[0038] The shock-absorbing auxiliary supporting foot 6 bolt 601 is provided with a hexagonal lock nut 602 and a washer 603, and the bolt 601 can pass through the supporting foot mounting hole 702 on the No...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com