Highly-erected steel bar grating

A steel grating, high-profile technology, applied in the field of steel grating, can solve the problems of low height and inability to meet installation requirements, and achieve the effect of improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

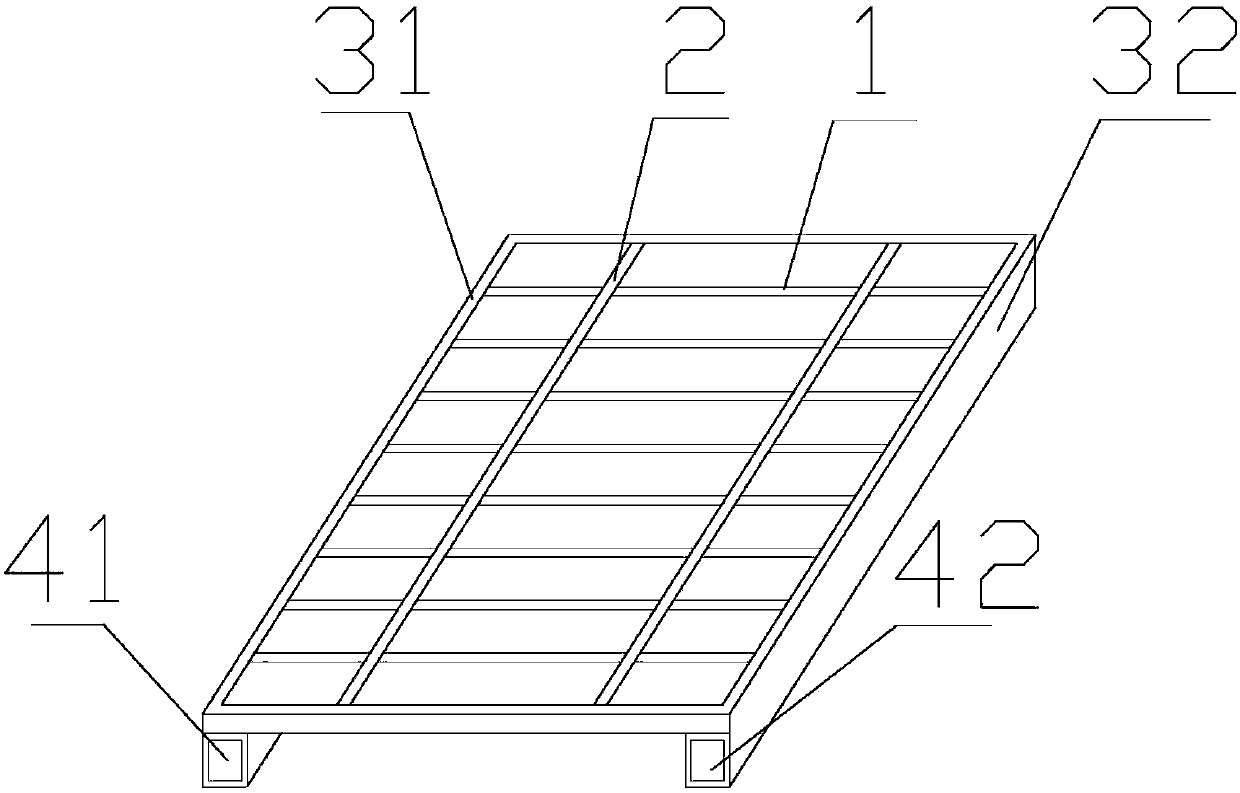

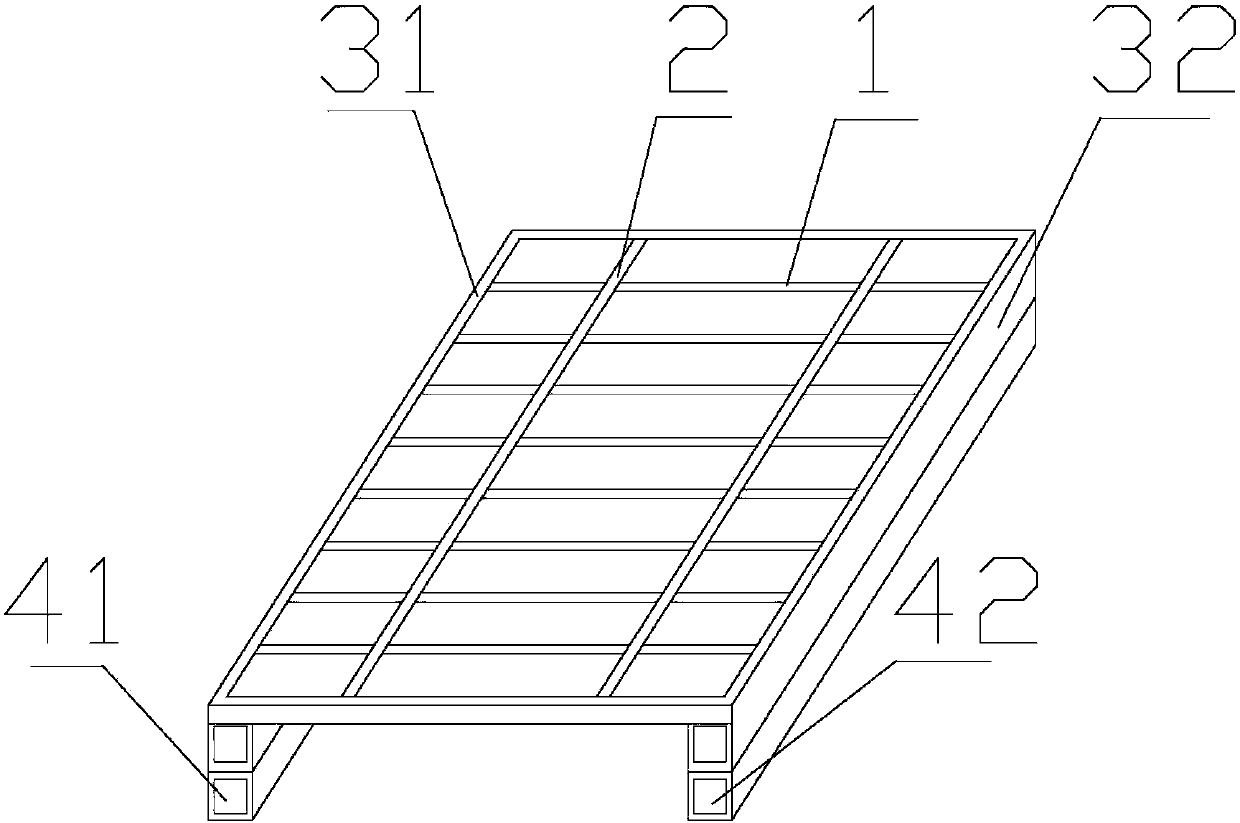

[0010] Such as figure 1 and figure 2 as shown, figure 1 It is a structural schematic diagram of an elevated steel grating proposed by the present invention, figure 2 It is a schematic structural diagram of an elevated steel grating proposed in the second embodiment of the present invention.

[0011] refer to figure 1 and figure 2 , an elevated steel grating proposed by the present invention, including a plurality of flat steels 1, a plurality of twisted square steels 2, two surrounding steels 31, 32 and two equal-height overhead fittings 41, 42, two The overhead fittings 41, 42 are both made of a square steel pipe or the two overhead fittings 41, 42 are welded up and down by two square steel pipes; a plurality of twisted square steel bars 2 are placed horizontally on a plurality of evenly arranged The flat steel 1 is fixedly connected by pressure welding, the two surrounding steel 31, 32 are transversely welded on the two end faces of the multiple flat steel 1, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com