Efficient honey extrusion device

An extrusion device and high-efficiency technology, which is applied in the field of high-efficiency honey extrusion devices, can solve the problems of low honey extraction rate, achieve the effect of improving honey output rate, avoiding troubles, and avoiding missing points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

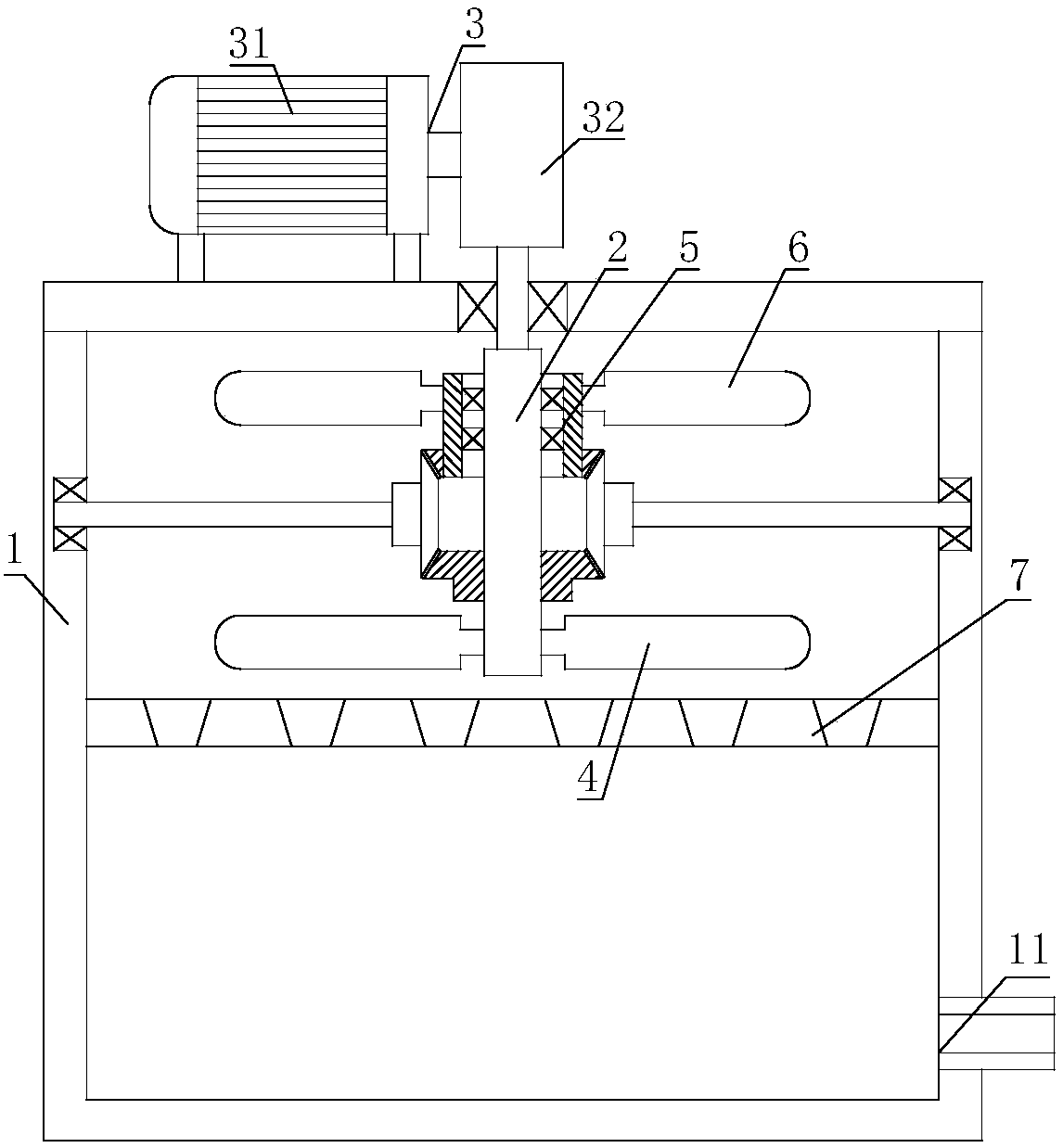

[0022] Such as figure 1 with figure 2 As shown, the present invention includes a box body 1, and a rotating shaft 2 is connected to the box body 1 through a bearing, a driving mechanism 3 for driving the rotating shaft 2 to rotate is installed on the box body 1, and a forward stirring paddle 4 and a rotating shaft 2 are respectively installed on the rotating shaft 2. The reversing mechanism 5 and the reversing mechanism 5 are equipped with a reverse stirring paddle 6; a filter plate 7 is arranged in the box body 1, and the filter plate 7 is located below the rotating shaft 2, and a honey outlet 11 is arranged at the bottom of the box body 1.

[0023] A reversing mechanism 5 is installed on the rotating shaft 2 of the present invention, so that after reversing, the rotation direction of the reverse stirring paddle 6 is opposite to that of the forward stirring paddle 4 . The forward stirring paddle 4 and the reverse stirring paddle 6 fully hit the honeycomb from two directions...

Embodiment 2

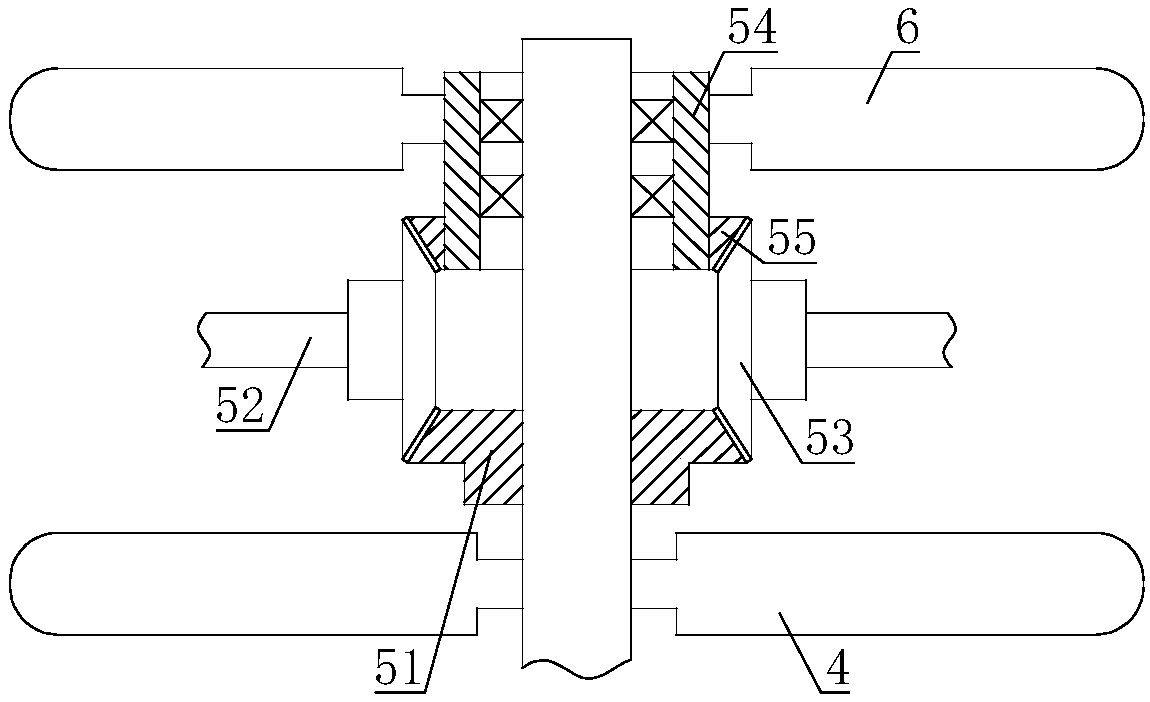

[0025] On the basis of Embodiment 1, the reversing mechanism 5 includes a driving bevel gear 51, the driving bevel gear 51 is fixed on the rotating shaft 2, an intermediate rod 52 is connected to the box body 1 through a bearing, and a transmission cone is fixed on the intermediate rod 52 Gear 53, the driving bevel gear 51 meshes with the transmission bevel gear 53; the rotating shaft 2 is connected with a sleeve 54 through a bearing, the sleeve 54 is fixed with a driven bevel gear 55, and the driven bevel gear 55 meshes with the transmission bevel gear 53; The stirring paddle 6 is fixed on the sleeve 54 .

[0026] When the rotating shaft 2 rotates in a certain direction, the driving bevel gear 51 is transmitted with the driving bevel gear 53, and the driving bevel gear 53 is transmitting with the driven bevel gear 55, then the driven bevel gear 55 and the driving bevel gear 51 rotate in the opposite direction. The cylinder 54 and the reverse stirring paddle 6 rotate together ...

Embodiment 3

[0028] On the basis of the first or second embodiment, the forward stirring paddles 4 and the reverse stirring paddles 6 are in several groups, and the forward stirring paddles 4 and the reverse stirring paddles 6 are arranged at intervals.

[0029] Multiple groups of forward stirring paddles 4 and reverse stirring paddles 6 are arranged at intervals, so that honey can be squeezed out more fully to avoid missing points.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com