Method for improving yield of humic acid salt prepared from weathered coal

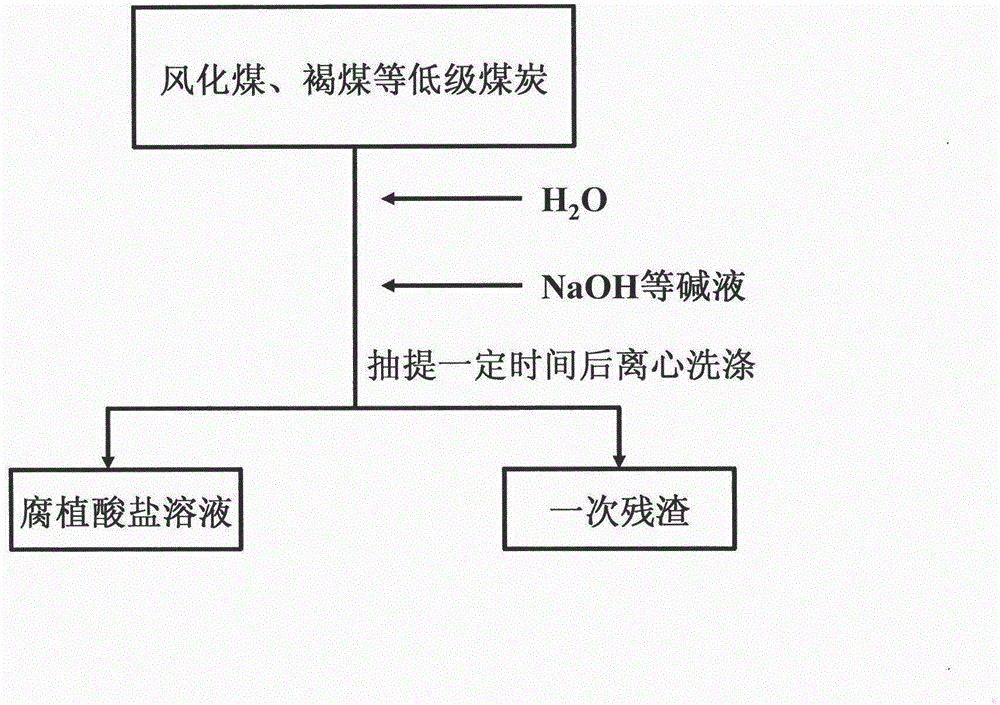

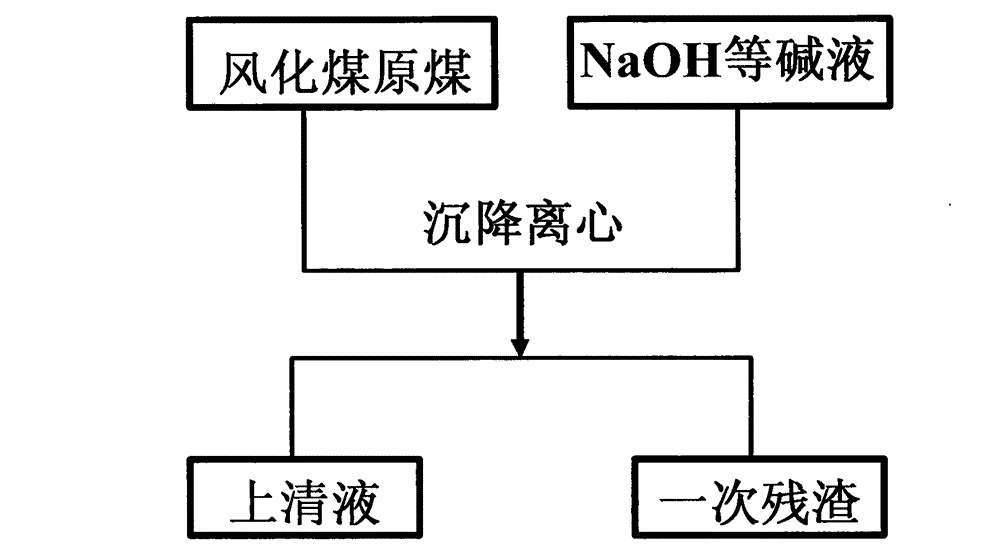

A humate yield and weathered coal technology, which is applied in the field of applied chemistry where nano-catalysts catalyze the conversion of weathered coal or lignite into humic acid, can solve the problems of long reaction time, low energy consumption, and short cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

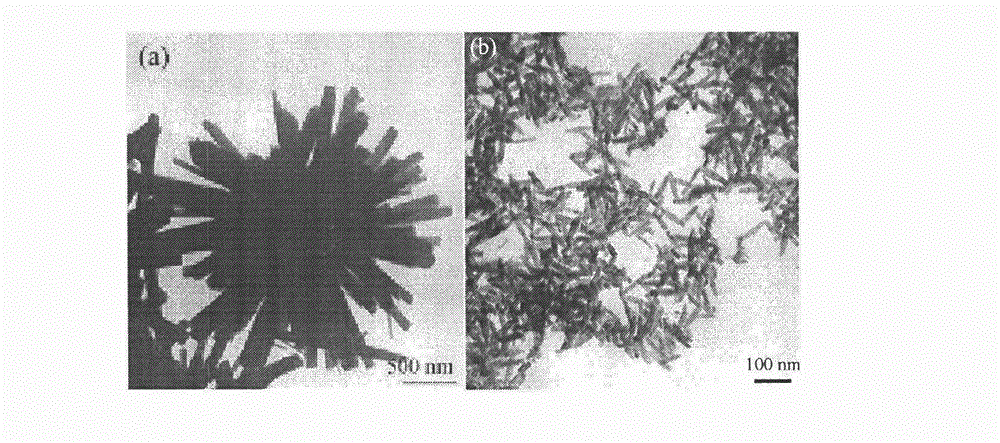

[0022] (1) Take by weighing 5g weathered coal or lignite residue after humic acid extraction (called primary residue), add 0.165g NaOH to it successively, 0.085g nano-CuO, 16.5ml concentration is 1% sodium hypochlorite or potassium hypochlorite, normal temperature Stir vigorously for 1 hour, and centrifuge to separate the humate solution and secondary residue. (2) Add 0.165g NaOH, 16.5ml sodium hypochlorite or potassium hypochlorite with a concentration of 1% to the secondary residue in sequence, stir vigorously at room temperature for 1 hour and then centrifuge to separate the humate solution and the tertiary residue. (3) Add 0.165g NaOH, 16.5ml sodium hypochlorite or potassium hypochlorite with a concentration of 1% to the third residue, stir vigorously at room temperature for 1 hour, and centrifuge to separate the humate solution and the fourth residue. (4) Add 0.165g NaOH, 16.5ml sodium hypochlorite or potassium hypochlorite with a concentration of 1% to the four residues,...

Embodiment 2

[0025](1) Take by weighing 5g weathered coal or lignite residue after humic acid extraction (called primary residue), add 0.165g NaOH to it successively, 0.134g nano-ZnO, 16.5ml concentration is 0.5% sodium hypochlorite or potassium hypochlorite, normal temperature Under vigorous stirring for 1 hour, centrifuge to separate the humate solution and secondary residue. (2) Add 0.165g NaOH, 16.5ml sodium hypochlorite or potassium hypochlorite with a concentration of 0.5% to the secondary residue, stir vigorously at room temperature for 1 hour and then centrifuge to separate the humate solution and the tertiary residue. (3) Add 0.165g NaOH, 16.5ml sodium hypochlorite or potassium hypochlorite with a concentration of 0.5% to the third residue, stir vigorously at room temperature for 1 hour, and centrifuge to separate the humate solution and the fourth residue. (4) Add 0.165g NaOH and 16.5ml of 0.5% sodium hypochlorite or potassium hypochlorite to the four residues, stir vigorously at...

Embodiment 3

[0028] (1) Take by weighing 5g weathered coal or lignite residue after humic acid extraction (called primary residue), add 0.165g NaOH to it successively, 0.2g nanometer FeOOH, 16.5ml concentration is 2% sodium hypochlorite or potassium hypochlorite, normal temperature Stir vigorously for 1 hour, and centrifuge to separate the humate solution and secondary residue. (2) Add 0.165g NaOH, 16.5ml sodium hypochlorite or potassium hypochlorite with a concentration of 2% to the secondary residue, stir vigorously at room temperature for 1 hour, and then centrifuge to separate the humate solution and the tertiary residue. (3) Add 0.165g NaOH, 16.5ml sodium hypochlorite or potassium hypochlorite with a concentration of 2% to the three residues, stir vigorously at room temperature for 1 hour, and centrifuge to separate the humate solution and the four residues. (4) Add 0.165g NaOH, 16.5ml of 2% sodium hypochlorite or potassium hypochlorite to the four residues, stir vigorously at room te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com