Method for recovering indium from indium-containing material

A material and content technology, applied in the direction of improving process efficiency, can solve the problems of low leaching rate, high product impurity content, low extraction rate, etc., and achieve the effect of strong operability, simple process operation and obvious technical advantages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

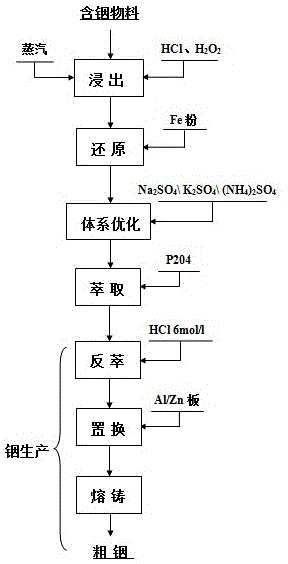

[0038] The implementation of the present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

[0039] to combine figure 1 As shown, the specific production process of recovering indium from indium-containing materials according to the embodiment of the present invention is as follows.

[0040] 1. Leaching

[0041] According to In in the material 2 S 3 Add a certain proportion of hydrochloric acid, and add steam to heat, and then add oxidant when heated to a certain temperature, the specific parameters are as follows:

[0042] (1) When leaching, add hydrochloric acid according to the liquid-solid ratio of 3~5:1;

[0043] (2) Acidity (i.e. hydrogen ion concentration) is 6~8mol / l;

[0044] (3) The amount of oxidant to be added takes hydrogen peroxide as an example, according to the In 2 S 3 content according to In 2 S 3 :H 2 o 2 Add hydrogen peroxide at a molar ratio of 1:1.5~3;

[0045] (4) The leaching temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com