A method and system for automatic control of tundish liquid level

A technology of automatic liquid level control and tundish, applied in the field of continuous casting, can solve problems such as reducing metal yield, and achieve the effects of improving metal yield, reducing influence and eliminating vortex slag entrainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

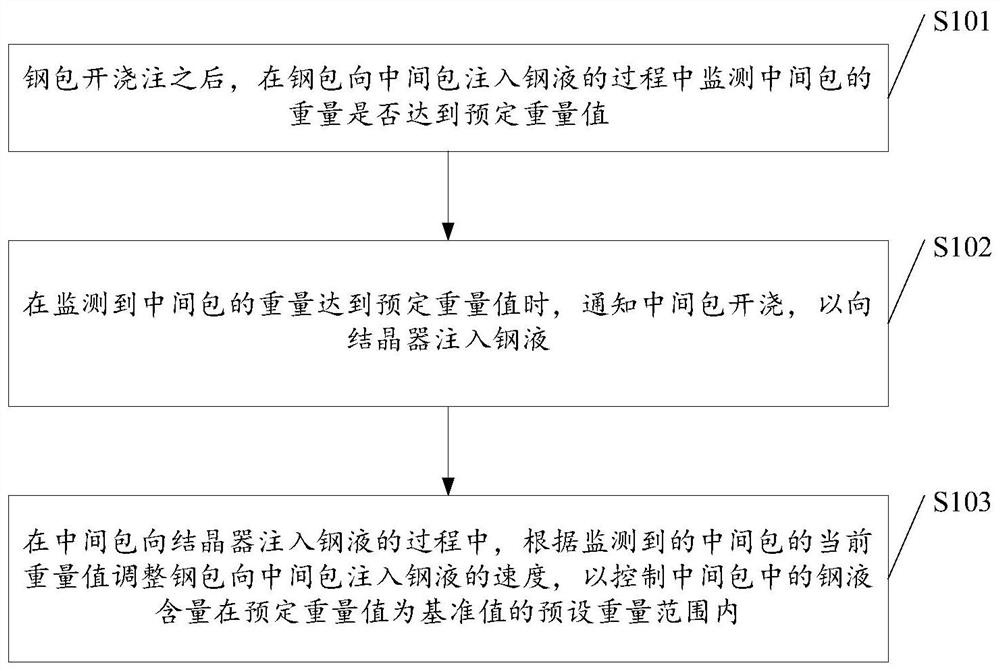

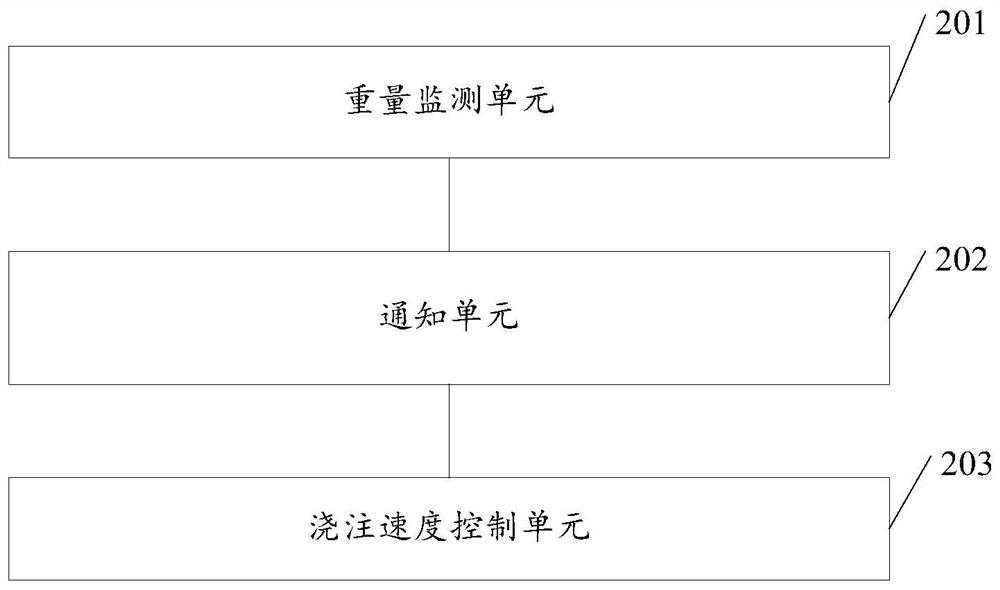

[0044] In view of the technical problem in the prior art that the technical means to prevent ladle slag curling will reduce the metal yield, the embodiment of the present invention provides an automatic control method and system for the tundish liquid level, the general idea is as follows:

[0045] When the weight of the tundish is monitored to reach the predetermined weight value, the tundish is notified to start pouring to inject molten steel into the mold; during the process of injecting molten steel into the mold, the ladle is adjusted according to the monitored current weight value of the tundish The speed of injecting molten steel into the tundish is to control the content of molten steel in the tundish within the preset weight range of the predetermined weight value as the reference value, thereby interfering with the generation of vortices in the ladle, thereby effectively eliminating the vortex slag of the ladle, In order to improve the purity of molten steel, the spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com