A method and system for automatic control of tundish liquid level

A liquid level automatic control and tundish technology, applied in the field of continuous casting, can solve the problems of limited adjustable angle of the ladle slide, easy to produce large errors, interference with the ladle, etc., to improve the purity of molten steel, avoid detection errors, improve Effect of strand quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

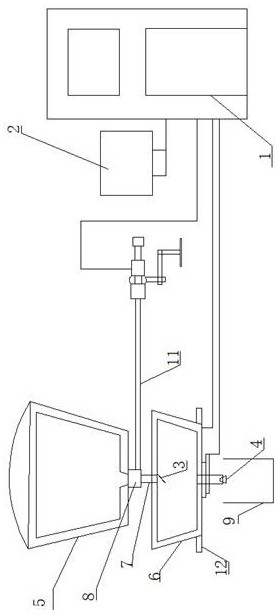

[0039] like Figure 1-4 As shown, the embodiment of the present invention provides a tundish liquid level automatic control system, including a PLC controller 1, an intelligent control terminal 2, a bale 5, a tundish 6, a long water pipe 7, a bale slide 8, and a crystallizer 9 , the bale slide 8 is set at the liquid outlet at the bottom of the bale 5, on which a pulse switch is arranged, the liquid outlet at the bottom of the bale 5 is connected with the tundish 6 through the long water pipe 7, and the lower end of the tundish 6 is symmetrical on both sides A set of weighing heads 12 is provided, a pouring pipe is provided at the bottom of the tundish 6, a proportional valve is provided in the pouring pipe, and a crystallizer 9 is provided below; it also includes:

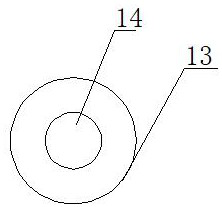

[0040] A group of pressure sensors 13 adapted to the weighing head 12 for realizing the weight measurement of the tundish;

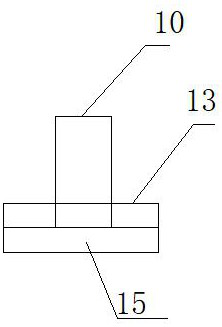

[0041] A hydraulic telescopic rod 10 for lifting the weighing head 12 so that the weighi...

Embodiment 2

[0050] like Figure 5 As shown, the embodiment of the present invention provides an automatic control method for the liquid level of the tundish, including the following steps:

[0051] S1. Inject a sufficient amount of molten steel into the ladle 5, and at the same time adjust the hydraulic telescopic rod so that the weighing head is offset against the pressure sensor 13;

[0052] S2. Open the ladle slide 8 through the PLC controller, so that the molten steel in the ladle 5 is injected into the tundish 6 through the liquid outlet at the bottom through the long water pipe 7, and monitor the tundish 6 in real time through the pressure sensor during the injection of molten steel the weight of;

[0053] S3. The PLC controller receives the weight signal sent by the pressure sensor, and realizes the evaluation of the weight signal, and controls the proportional valve, the snake-shaped manipulator, and the pulse switch according to the evaluation result to realize the control of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com