Blade rear edge bonding angle male die preparing method and blade rear edge bonding angle preparing method

A blade trailing edge and bonding angle technology, which is applied in the preparation of blade trailing edge bonding angle male molds and blade trailing edge bonding angles, and can solve problems such as irregular trailing edge cavity structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

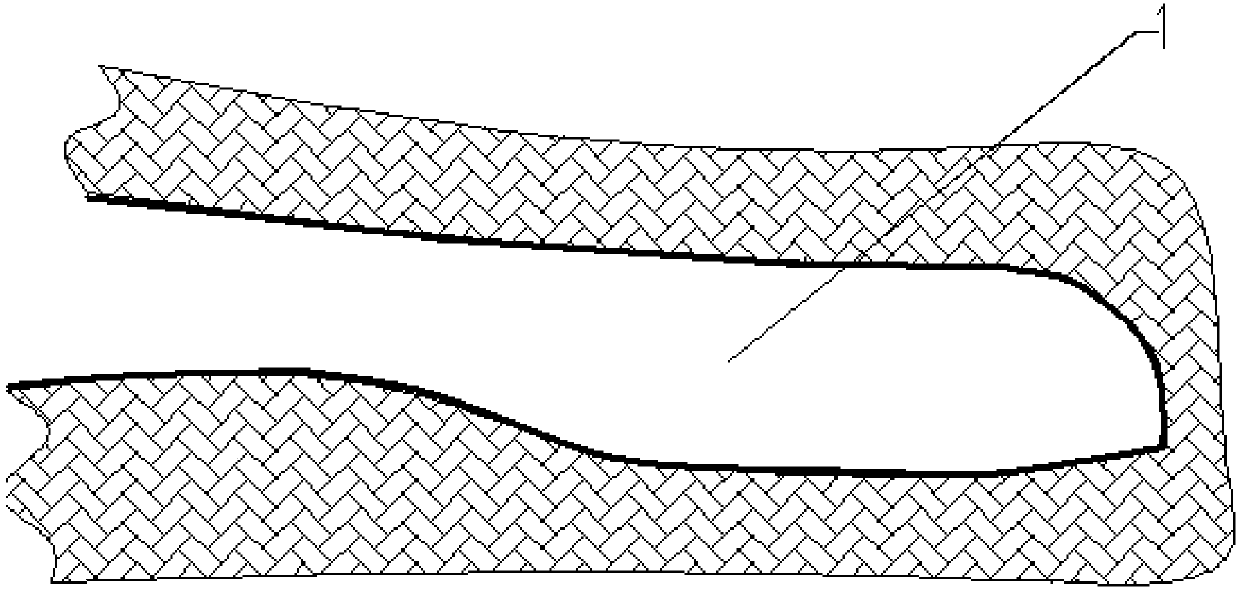

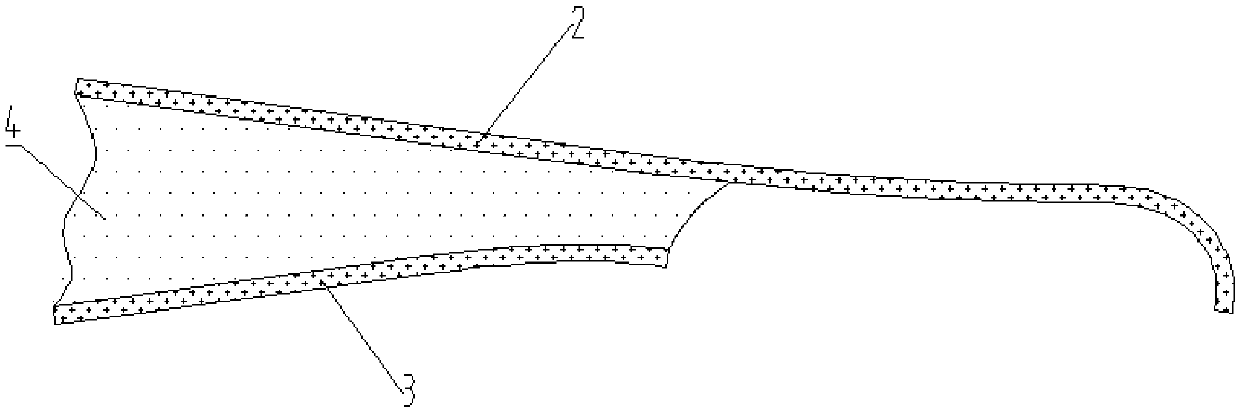

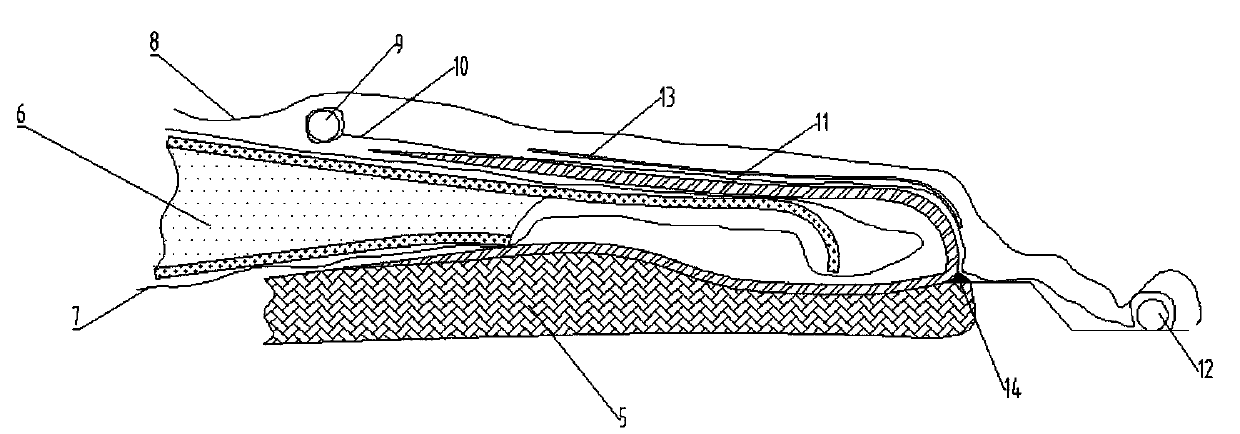

[0037] Refer to attached figure 1 As shown, the present invention is used to prepare a trailing edge bonding angle male mold and a trailing edge bonding angle suitable for an irregular cavity with a large space at both ends and a small space in the middle, which is suitable for the inner cavity of the trailing edge of a wind power blade. From attached figure 1 It can be seen that the bonding angle area 1 of the trailing edge of the blade is an "Ω"-shaped structure with a small mouth and a large cavity. If the bonding angle male mold is prepared according to the conventional bonding angle male mold preparation method, the After it is finished, it will not be able to be removed from the "Ω"-shaped structure with a small mouth and a large cavity. For this shortcoming, refer to the attached figure 2 As shown, the preparation method of the blade trailing edge bonding angle male mold of the present invention is as follows, comprising steps:

[0038] (1) Simulate the bonding angl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com