A polymer for high temperature resistant acid fracturing and its preparation method

An acid fracturing and polymer technology, applied in the field of drilling, which can solve the problems of slow water solubility and acid solubility, uncontrolled cross-linked acid, high viscosity, and inability to meet the requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

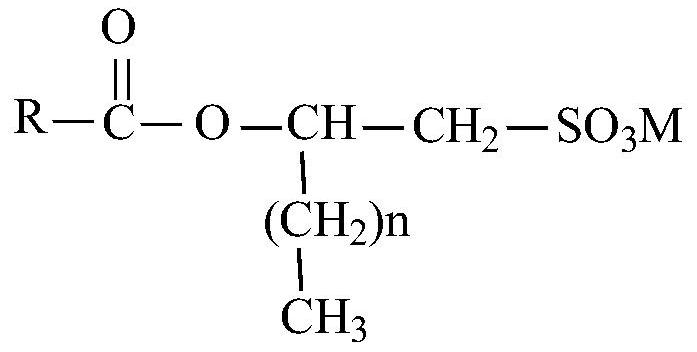

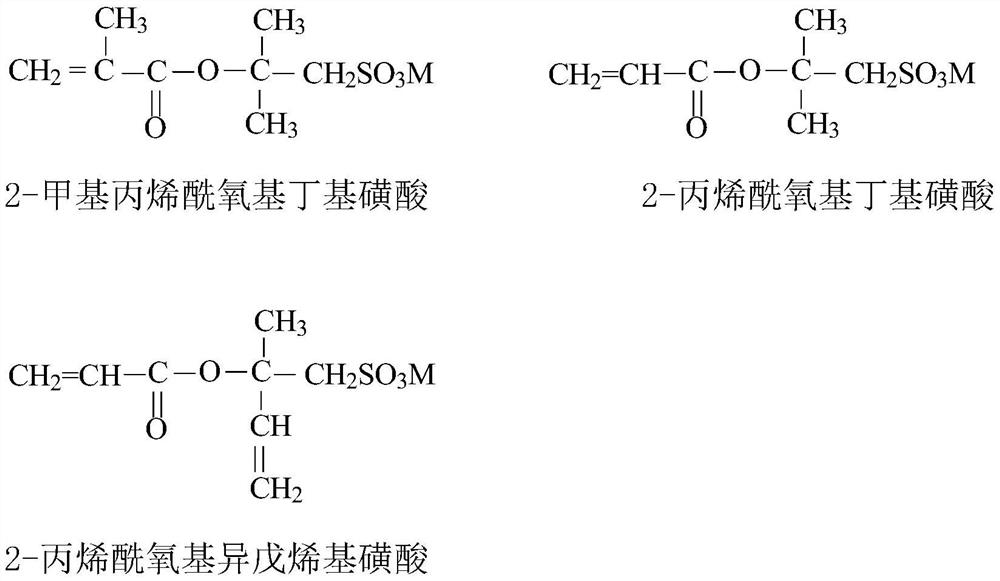

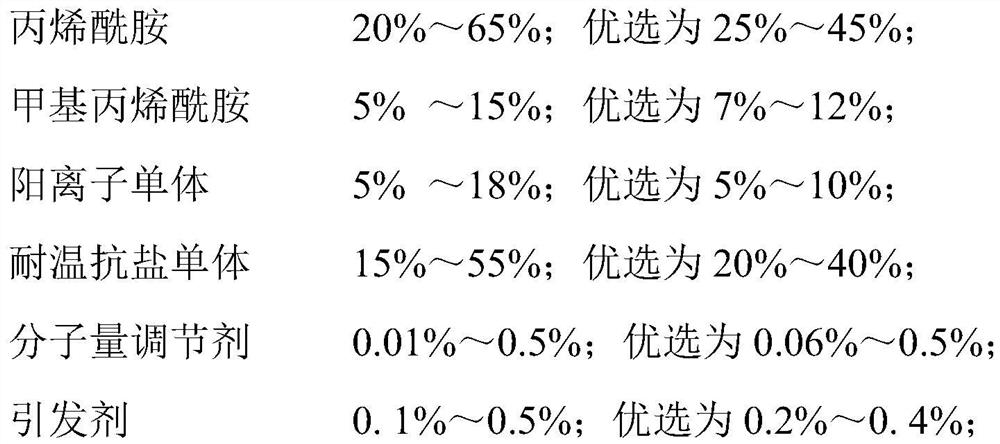

Method used

Image

Examples

Embodiment 1

[0036] 20g of acrylamide, 4g of methacrylamide, 5g of 75% solution of methacryloyloxyethyltrimethylammonium chloride, 28g of temperature-resistant and salt-resistant monomer (2-methacryloyloxybutylsulfonic acid) Stirring at 300r / min, add 160ml of water into the reactor placed in a constant temperature water bath, stir well, add 0.05g of molecular weight modifier polyoxyethylene diacrylate, adjust the polymerization system with 20% sodium hydroxide aqueous solution The pH value is 7. Stir for about 30 minutes by blowing nitrogen to deoxygenate, raise the temperature of the polymerization solution to 45°C, then add 0.06 g of potassium persulfate and sodium sulfite respectively to initiate polymerization, and continue to keep blowing nitrogen for about 20 minutes; polymerize at a constant temperature in a constant temperature water bath After 8 hours, take out and shear granulate, dry and pulverize to obtain the polymer for high temperature resistant acidification fracturing.

Embodiment 2

[0038] 30g of acrylamide, 6g of methacrylamide, 8g of acryloyloxyethyltrimethylammonium chloride 75% solution, 20g of temperature-resistant and salt-resistant monomer (2-acryloyloxybutylsulfonic acid) at 300r / min Add 175ml of water successively to a reactor placed in a constant temperature water bath under stirring at a rotating speed. After stirring evenly, add 0.035g of molecular weight regulator ethylene glycol diacrylate, and adjust the pH of the polymerization system to 8 with 20% potassium hydroxide aqueous solution. , and stirred for about 25 minutes by blowing nitrogen to deoxygenate, raising the temperature of the polymerization solution to 35°C, then adding 0.12 g of potassium persulfate and sodium sulfite respectively to initiate polymerization, and continuing to keep blowing nitrogen for about 25 minutes; Cutting and granulating, drying and pulverizing to obtain the high-temperature-resistant polymer for acidification and fracturing.

Embodiment 3

[0040] 13g of acrylamide, 8g of methacrylamide, 8g of dimethyl diallyl ammonium chloride 70% solution, 32g of temperature-resistant and salt-resistant monomer (2-acryloyloxy isopentenyl sulfonic acid) at 300r / Add 180ml of water successively to the reactor placed in a constant temperature water bath under stirring at min speed, stir evenly, add 0.28g of molecular weight regulator butanediol diacrylate, adjust the pH of the polymerization system with 20% sodium hydroxide aqueous solution 9. Stir for about 30 minutes with nitrogen gas to deoxygenate, raise the temperature of the polymerization solution to 50°C, then add 0.23 g each of potassium persulfate and sodium sulfite to initiate polymerization, and continue to maintain nitrogen gas for about 20 minutes; keep the constant temperature polymerization reaction in a constant temperature water bath for 10 hours, take out Shear granulation, drying, crushing to obtain high temperature resistant polymer for acidification fracturing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com