Double-layer integrated weaving control method of drum bagging cloth

A control method and drum technology, applied to textiles, papermaking, textiles, looms, etc., can solve problems such as inability to realize automatic production, complicated operation, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

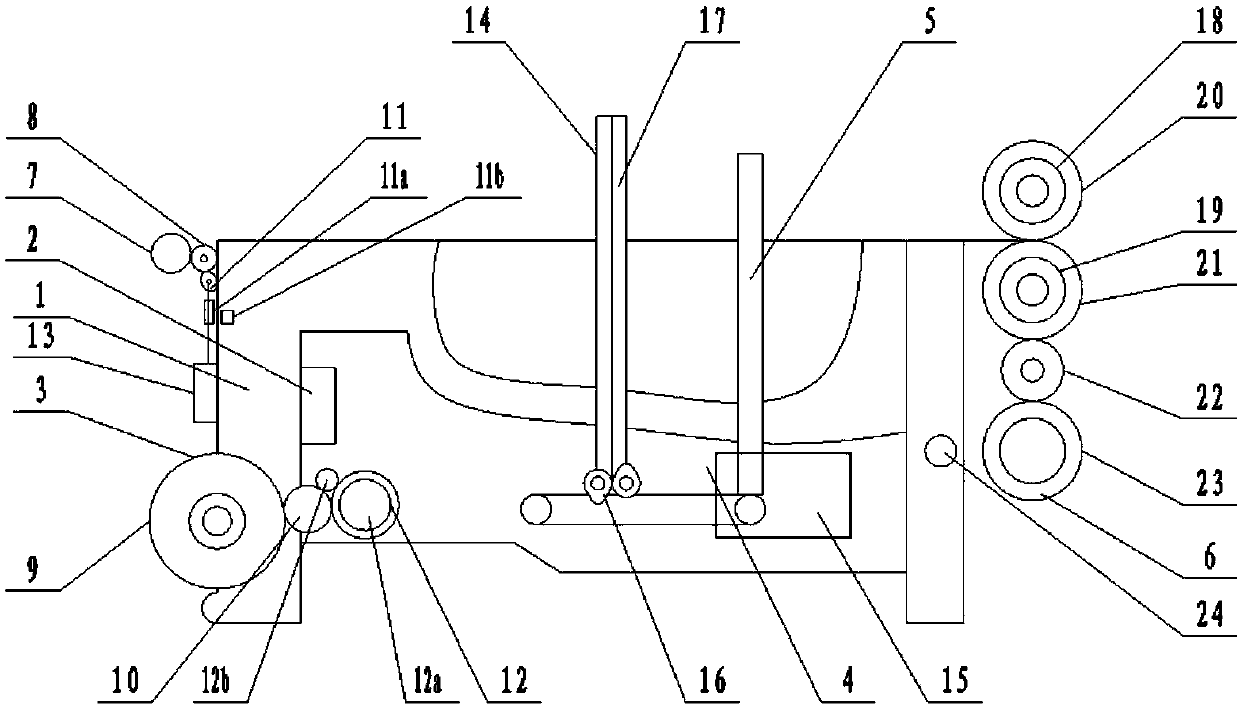

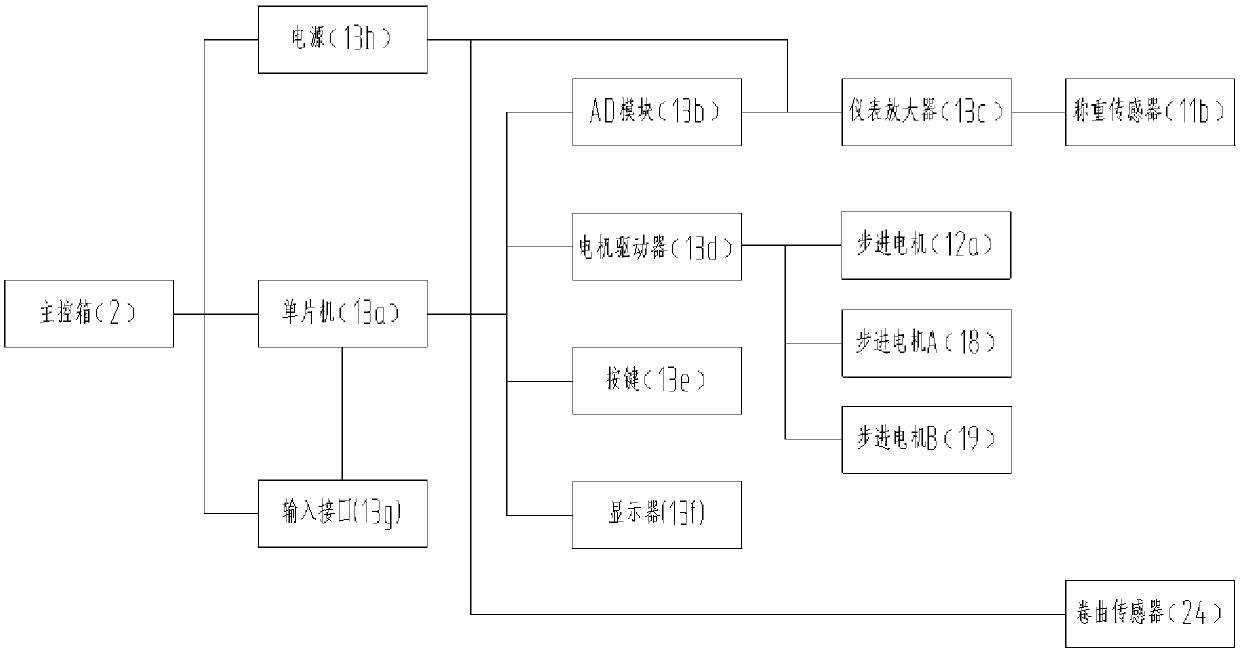

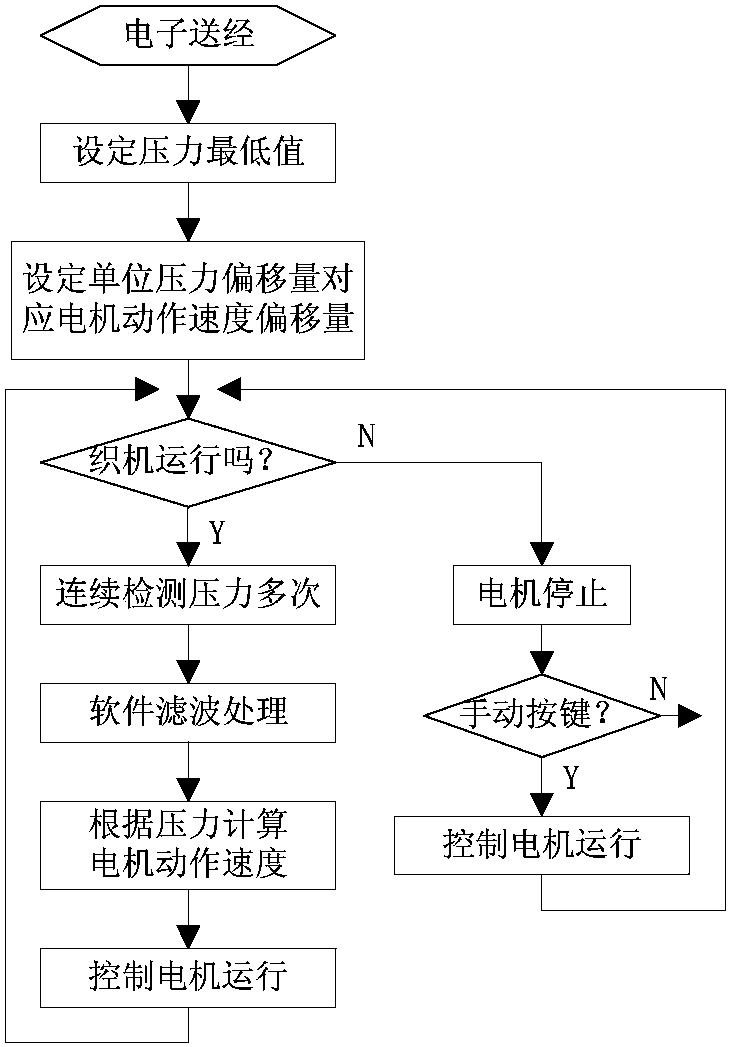

[0024] Such as figure 1 , figure 2 As shown, the present invention designs an intelligent drum bagged cloth weaving control device, the main body is a shuttle loom support 1, a main control box 2 is arranged on the shuttle loom support 1, and the front end of the shuttle loom support 1 is arranged There is an intelligent electronic warp let-off device 3, a heald frame opening device 4 is arranged inside the shuttle loom support 1, and a weft insertion device 5 and an intelligent crimping device 6 are provided at the rear end of the shuttle loom support 1.

[0025] Wherein the intelligent electronic let-off device 3 comprises an eccentric stick 7, a swing lever 8, a warp let-off beam 9, a gear linkage device A 10, a warp tension detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com