Turbomachine test bench with active noise control

A test bench and turbine technology, which is used in gas turbine engine testing, internal combustion engine testing, and engine testing, etc., can solve problems such as limited efficiency, and achieve the effects of cost reduction, outlet air passage shortening, and row number reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In the following description, the terms inner and outer refer to an orientation relative to the axis of rotation of the turbomachine. The axial direction corresponds to a direction along the rotational axis of the turbomachine. The radial direction is perpendicular to the axis of rotation. Upstream and downstream refer to the main flow direction in a turbomachine.

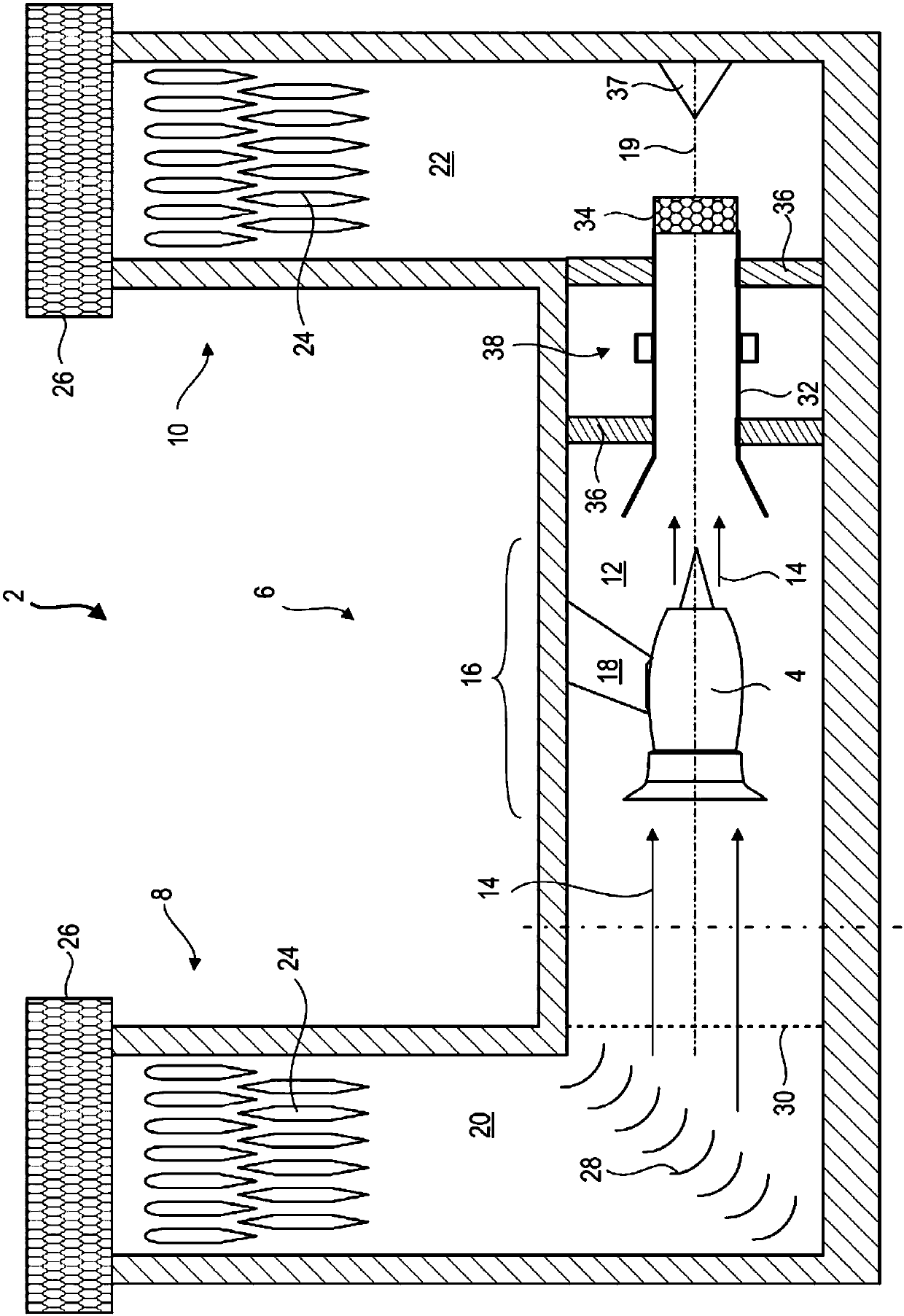

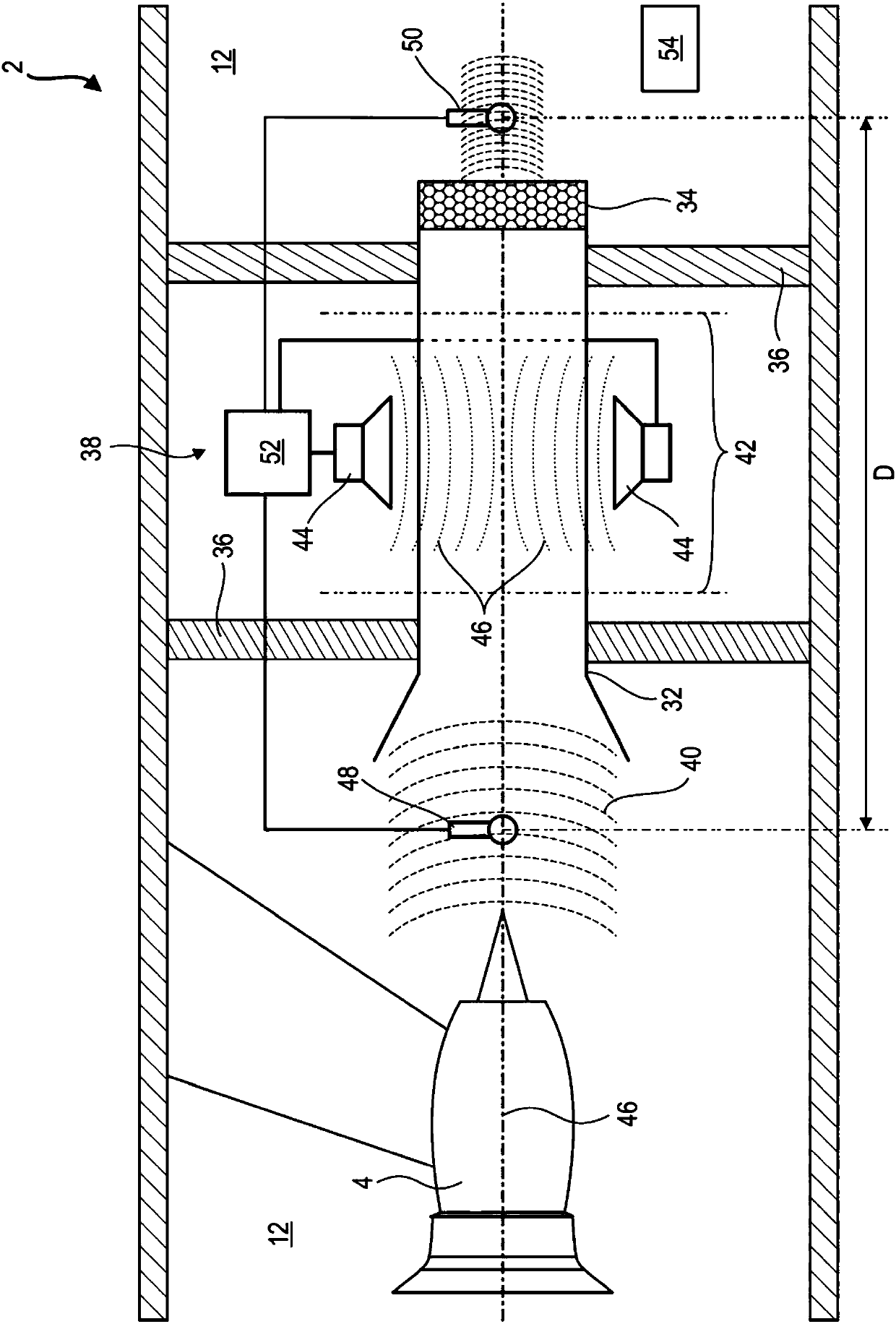

[0051] figure 1 A test rig 2 for an engine 4 is shown in a simplified manner, more specifically a test rig 2 for a turbine 4 , in particular for an aircraft turbojet engine 4 . The test stand 2 can accommodate a complete aircraft, or at least a part of an aircraft.

[0052] The test bench 2 forms the infrastructure, forming a structure. It comprises a channel 6 with an inlet 8 and an outlet 10 . The passageway 6 may comprise a corridor 12 which is substantially long and narrow. Its length may be greater than or equal to 60m. The length of the corridor 12 is such that the airflow 14 flows in a straight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com