Omission preventing tool box

A toolbox and tool technology, applied in the direction of manufacturing tools, tool storage devices, etc., can solve problems such as unfavorable use, complex locking structure, failure of alarm function, etc., and achieve the effects of improving versatility, reducing volume, and being easy to carry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

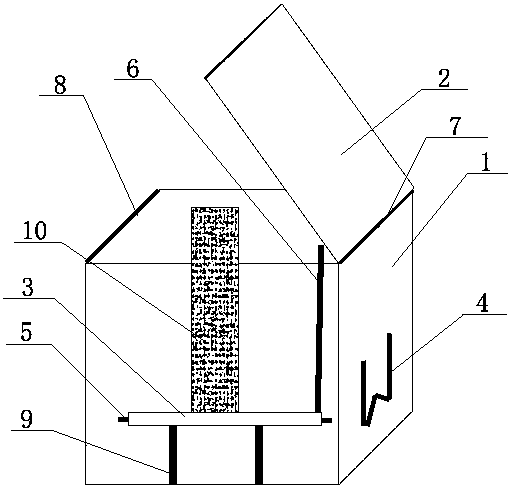

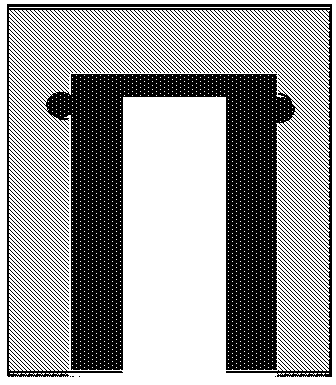

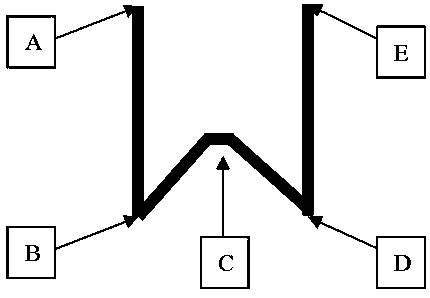

[0012] Such as figure 1 , figure 2 and image 3 As shown, an anti-missing toolbox of the present invention includes a plurality of tool storage boxes with different volumes for placing different types of tools, and two of the four outer sides of each of the tool storage boxes are set as Mutual-matching buckle structure, used for self-locking between adjacent tool storage boxes, the structure of the tool storage box is: including a box body 1, a box cover 2, a loading platform 3, and a limiting groove 4 , limit snap bead 5 and ejector rod 6, described box body 1 is the shell-like body of upper opening, and one end of described box cover 2 is hinged on the upper side of box body 1 by rotating shaft 7, makes box cover 2 The box body 1 can be movably matched, and the other end of the box cover 2 and the corresponding upper side of the box body 1 are provided with a magnetic locking bar 8, and the box cover 2 is locked in place by the magnetic locking bar 8. On the box body 1, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap