Automatic positioning imaging device for bridge crane

A bridge crane, automatic positioning technology, applied in the direction of walking bridge cranes, cranes, safety devices, etc., can solve problems such as blind spots of sight, achieve the effects of improved installation, rapid positioning, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

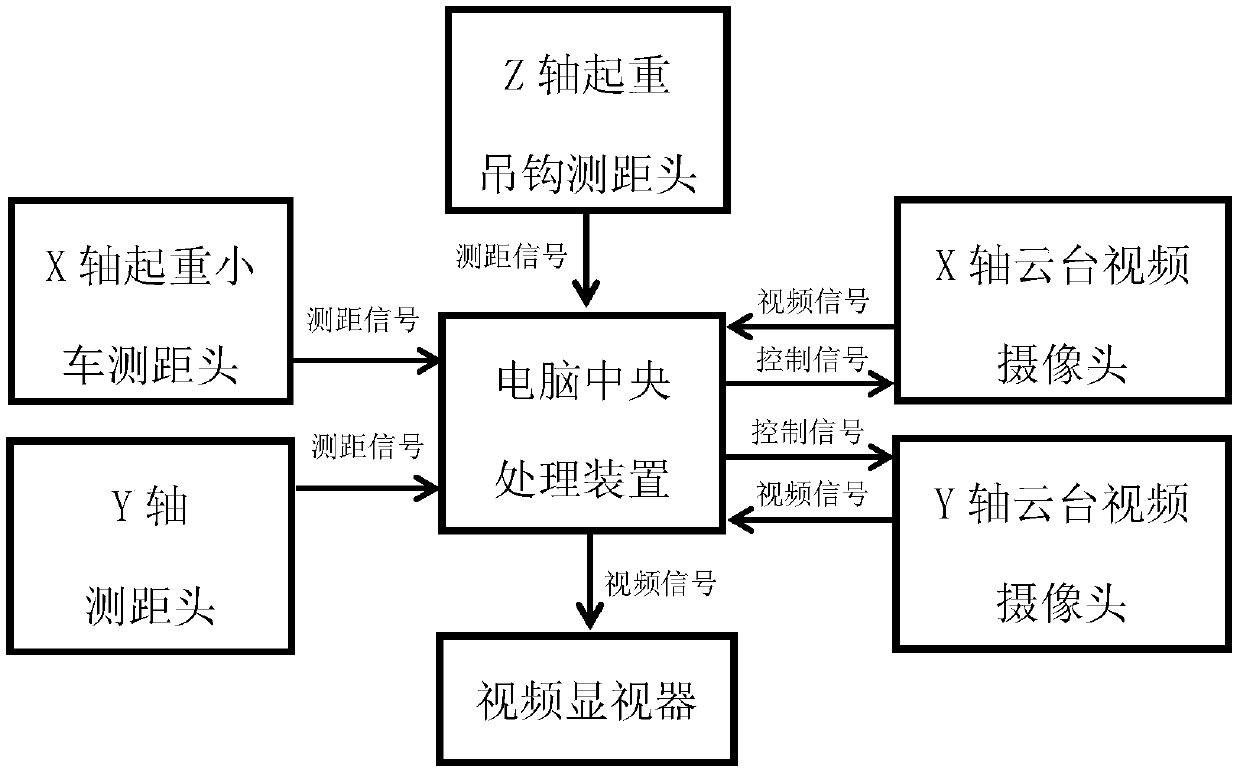

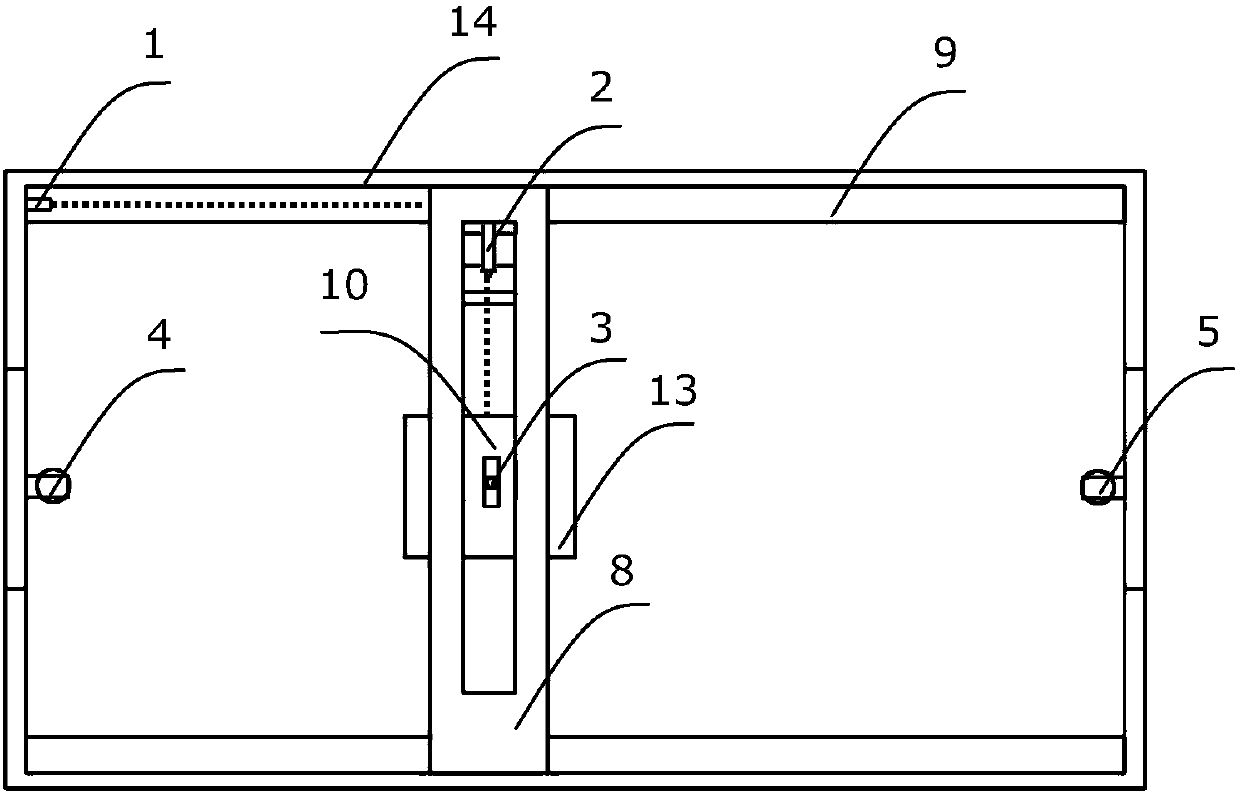

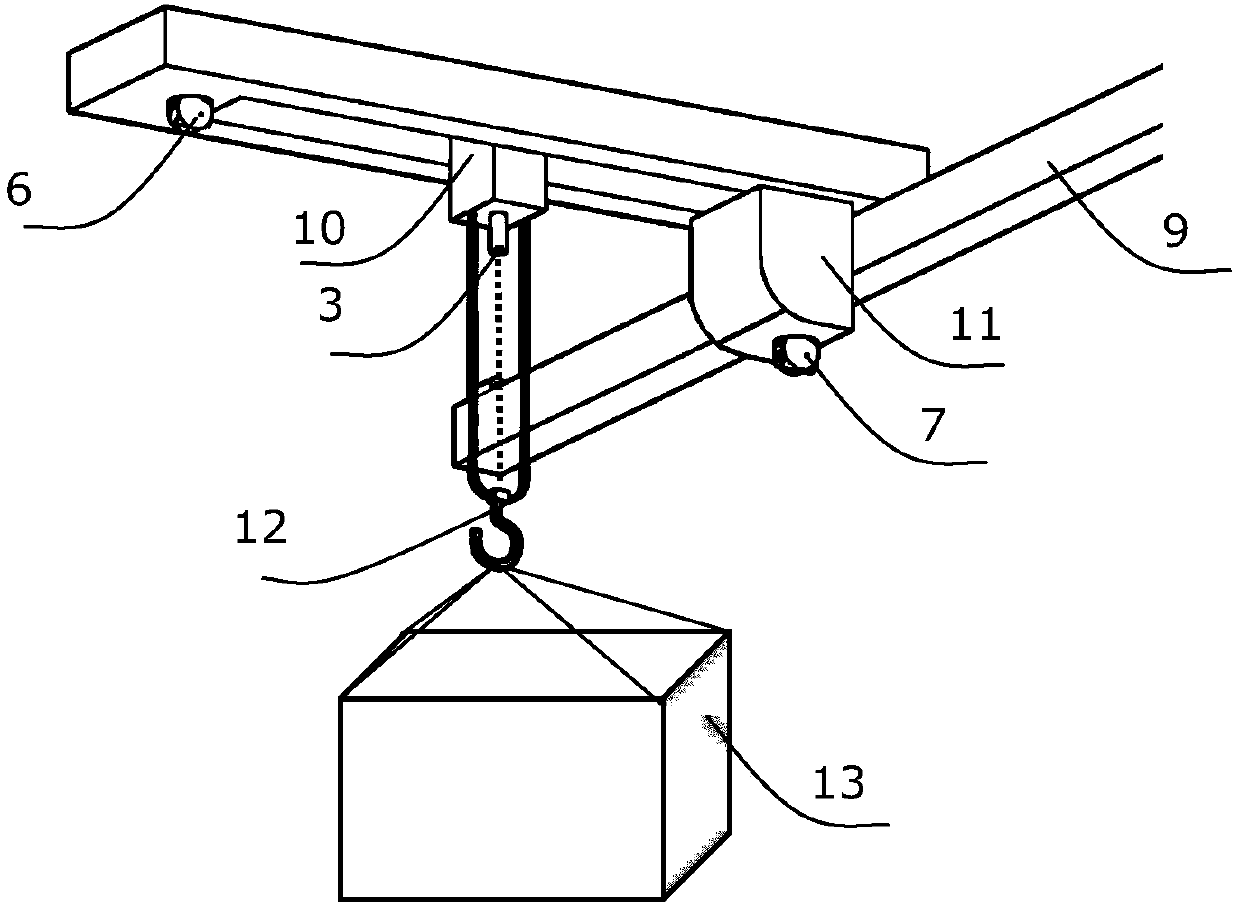

[0018] Depend on figure 1 As can be seen, the present invention comprises X-axis hoist trolley ranging head, X-axis cloud platform video camera, Y-axis ranging device, Z-axis lifting hook ranging head, Y-axis cloud platform video camera and central processing unit through wired or It is wirelessly connected, and the computer central processing unit is connected with the video monitor by wire or wirelessly.

[0019] The distance measuring head of the X-axis lifting trolley, the Y-axis distance measuring device, and the distance measuring head of the Z-axis lifting hook respectively obtain the moving distance data of the lifting trolley in the X-axis direction, the moving distance data of the main girder in the Y-axis direction, and the lifting distance data. The moving distance data of the hook in the Z-axis height direction is transmitted to the central processor through wired or wireless means, and the central processor transmits the spatial data of X, Y, and Z points to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com