Slide-plate-method slag-stopping tapping slide plate brick for converter

A sliding brick and sliding plate technology, which are applied in the field of refractory materials for converter tapping and slag-retaining tapping sliding bricks by the converter sliding plate method, can solve the problems affecting the working efficiency of the converter, affecting the service life of the product, and short service life, and reaching a wide range of industries. Application prospects, improving work efficiency, and reducing the effect of replacement frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

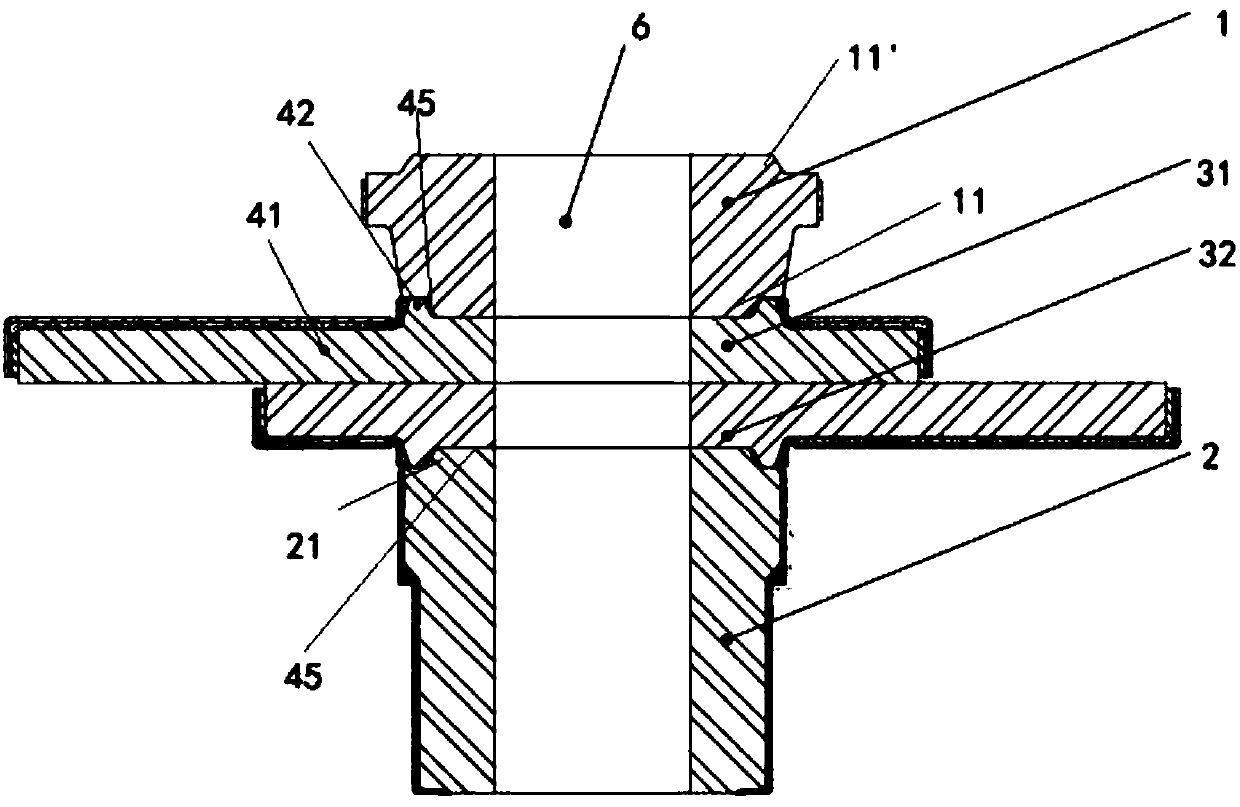

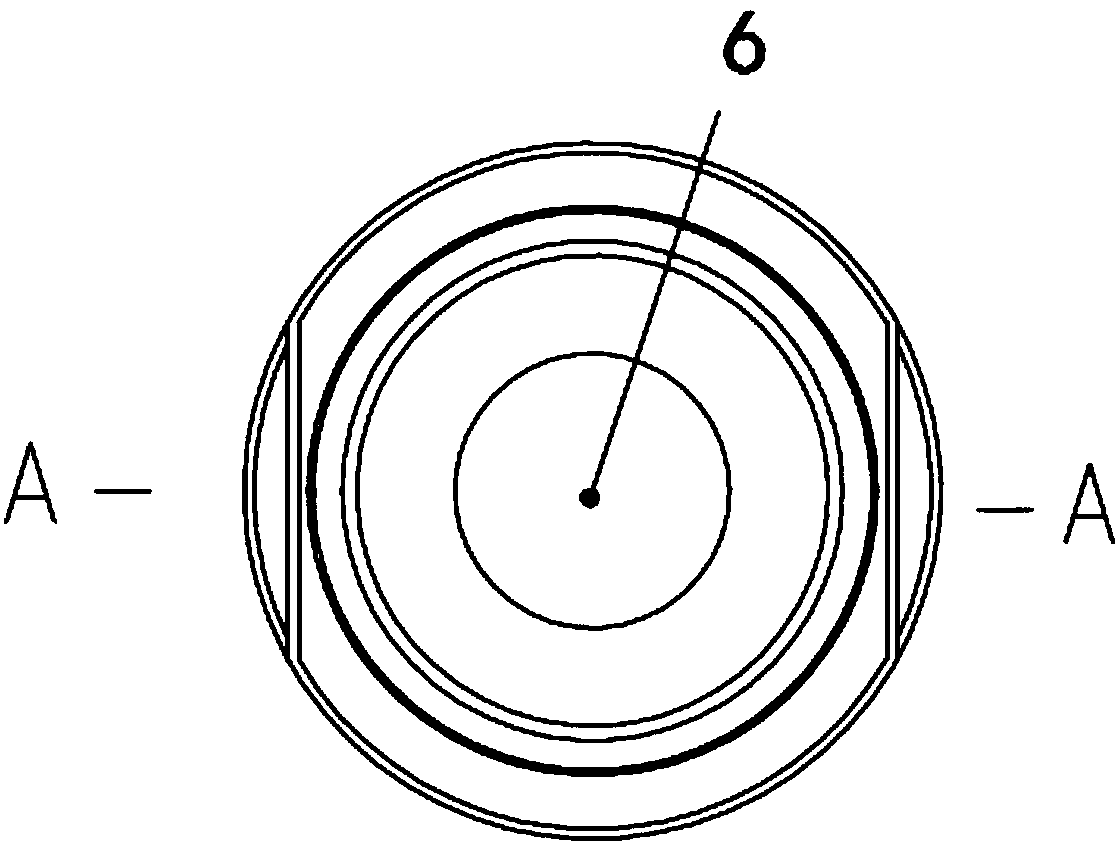

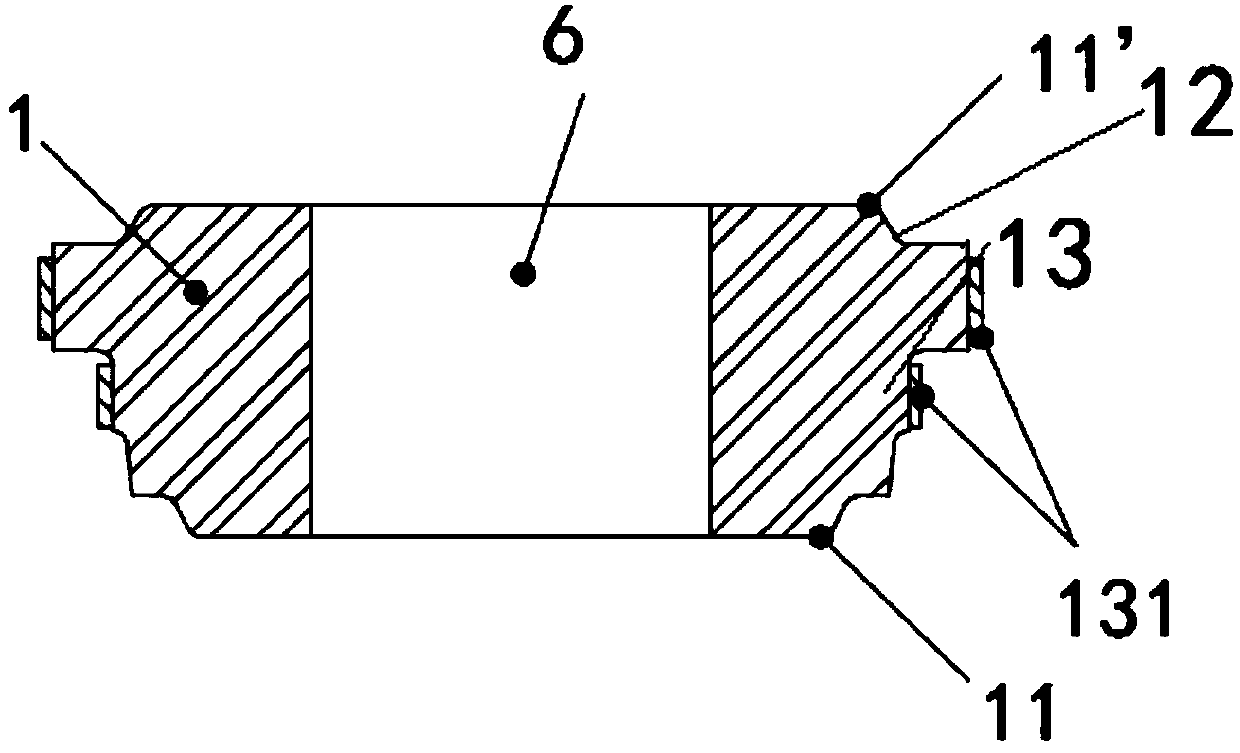

[0053] See Figure 1 to Figure 3 and Figure 18 As shown, in a preferred embodiment, a sliding brick for slag blocking and steel tapping by converter sliding method, including:

[0054] The inner nozzle brick 1, the upper and lower ends of the inner nozzle brick 1 are provided with first tenons 11 and 11'; the outer wall of the inner nozzle brick 1 is provided with a first annular boss 12 and a second annular boss 13 in turn; the first The annular boss 12 and the second annular boss 13 are respectively provided with a first steel hoop 131 .

[0055] The outer nozzle brick 2, the upper end of the outer nozzle brick 2 is provided with a second tenon 21.

[0056] The inner skateboard brick 31 and the outer skateboard brick 32, the structure of the inner skateboard brick 31 and the outer skateboard brick 32 are consistent,

[0057] Both the inner skateboard brick 31 and the outer skateboard brick 32 include a skateboard brick body 41 and a tenon 42; the skateboard brick body 41...

no. 2 example

[0065] Please see Figure 4 and 5 , the inner nozzle brick and the outer nozzle brick of this embodiment and figure 1 The inner nozzle brick 1 and the outer nozzle brick 2 of the first embodiment are the same. And the present embodiment also includes inner sliding bricks and outer sliding bricks with the same structure, and the installation methods of inner sliding bricks, outer sliding bricks, inner nozzle bricks and outer nozzle bricks are also the same as figure 1 The first embodiment is the same as in the first embodiment. At the same time, the flow steel hole 6 also runs through the inner nozzle brick, the inner slider brick, the outer slider brick and the outer nozzle brick in sequence. The difference is that:

[0066] Both the inner skateboard brick and the outer skateboard brick include a skateboard brick body 241, a tenon 242, a second steel hoop 243, a first steel sleeve 244, and a cement 245; the side of the skateboard brick body 241 is provided with a second stee...

no. 3 example

[0068] Please see Figure 6 and 7 , the inner nozzle brick and the outer nozzle brick of this embodiment and figure 1 The inner nozzle brick 1 and the outer nozzle brick 2 of the first embodiment are the same. And the present embodiment also includes inner sliding bricks and outer sliding bricks with the same structure, and the installation methods of inner sliding bricks, outer sliding bricks, inner nozzle bricks and outer nozzle bricks are also the same as figure 1 The first embodiment is the same as in the first embodiment. At the same time, the flow steel hole 6 also runs through the inner nozzle brick, the inner slider brick, the outer slider brick and the outer nozzle brick in sequence. The difference is that:

[0069] Both the inner skateboard brick and the outer skateboard brick include a skateboard brick body 341, a concave tenon 342, a second steel hoop 343, a first steel sleeve 344, a cement 345, an inlaid pipe brick 346 and a special cement 347; The tenon 342 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com